Showing results 2701 - 2800 of 4973

Right – EPA WaterSense-rated showerheads, faucets, and toilets contribute to both water and energy savings.

Right – Even house wrap is installed in the factory for these modular homes where each floor is factory assembled.

Right – Every seam and nail hole in these garage-to-house walls is sealed with tape.

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Fan with a cleanly cut and properly sized hole has been air sealed to drywall

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

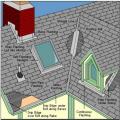

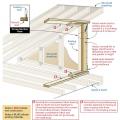

Right – Flashing is installed around chimney, skylight, vents, dormers, in valleys and at eaves

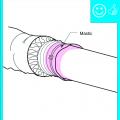

Right – Flex duct is properly connected to metal duct with a duct tie and connection is mastic sealed

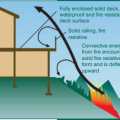

Right – Flex ducts are properly supported with straps that don’t pinch the insulation; closed-cell spray foam will be applied to the underside of the roof deck of this hot-humid climate home to provide an insulated attic space for the HVAC ducts.

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Foil-faced insulation was added after the crawlspace was dried and sealed by diverting water runoff, sealing off crawlspace windows and vents, and adding sump pumps and exhaust fan ventilation

Right – Foundation drainage mat was installed over the waterproof membrane that covers the sealed crawlspace window

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Furring strips provide a drainage and ventilation gap between the siding and the cork insulation.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Furring strips were installed to provide a 3/8-inch drainage plane over the rigid foam and under the fiber cement lap siding.

Right – Graphite enhanced EPS fills these SIP panels, providing additional insulation value.

Right – Half-inch furring strips provide a rain screen and air gap between the weather-resistant membrane and the fiber cement siding on the exterior walls of this marine-climate home.

Right – Holes were drilled into the I joists between floors to run the small-diameter HRV ducts.

Right – Home owner guidance for safe operation of fireplaces

Right – Horizontal overhangs on this house block sunlight in the summer while allowing it in during winter

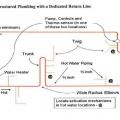

Right – Hot water from this heat pump water heater is distributed efficiently to each hot water use in the home through a central manifold via PEX piping.

Right – House without gutters has waterproof liner, drain tile, and gravel bed extending more than 5 feet from foundation

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – HVAC furnace filter is properly installed in cabinet with gasketed cover to prevent air leakage

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

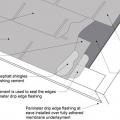

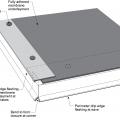

Right – If drip edge flashing is installed over fully adhered roof membrane at eaves, use flashing cement to seal the upper edge of the flashing

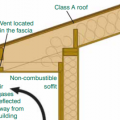

Right – In wildfire prone areas, using a flat soffit with venting on the fascia instead of an angled soffit with down-facing venting reduces the risk of catching rising embers.

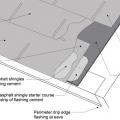

Right – Install asphalt shingles over a starter strip set in an 8-inch strip of flashing cement

Right – Insulated concrete form (ICF) blocks are stacked like bricks, then rebar is set horizontally and vertically in the plastic spacers, then concrete is poured; the rigid foam and spacers stay in place to add support and thermal resistance to the wall

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – Insulation installed to correct depth and will be aligned with air barrier

Right – Interior grade is elevated and flood vents are located slightly above interior grade

Right – Interior wood-to-wood seams around a window are sealed with tape to prevent air leakage.

Right – Joists between floors are air sealed to the ceiling drywall with canned spray foam along each joist-to-drywall-seam.

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

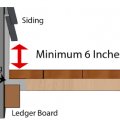

Right – Metal flashing is installed between the deck boards and house wall with the top of the flashing extending up behind the siding and the bottom of the flashing extending out and down over the ledger board

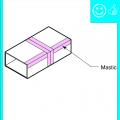

Right – Metal or fiberboard duct is mastic sealed at junction with duct register box

Right – Mineral wool batt insulation is cut to fit snuggly and to fully fill wall cavities with minimal voids and gaps.

Right – Moisture-resistant backing material has been used above and behind the tub enclosure.

Right – Mold- and termite-resistant borate-treated lumber are used to make the panels of this kit home which are connected with metal strapping for hurricane and wind resistance.

Right – Netted blown fiberglass insulation completely fills the wall cavities with no gaps or voids.

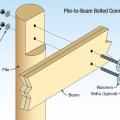

Right – Notch cut into pile takes less than 50% of cross section, cut is treated with wood preservative, and beam is installed with corrosion-resistant bolts.

Right – Open web floor joists can provide a space between floors for HVAC ducting.

Right – Open-cell spray foam is installed over closed-cell spray foam in this hybrid approach to achieve adequate attic ventilation while allowing some vapor permeability.

Right – Pavers provide a pervious ground surface allowing storm runoff to drain through to a gravel filtration and stormwater retention area below.

Right – PEX piping speeds hot water directly from the water heater to faucets through the attic in this slab-on-grade home.

Right – Photovoltaic solar panels are ready for installation on the roof of a DOE Zero Energy Ready certified home.

Right – Plastic tenting increases the height of the insulation above ducts that are located in the attic.

Right – Plumbing pipes have flanges that are sealed to the wall with caulk to prevent pest entry

Right – Polyethylene sheeting completely covers the aggregate and the footing with no tears or open seams

Right – Polyethylene sheeting is laid over aggregate and over footing to provide a capillary break between the ground and the slab and between the footing and the stem wall

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Possible Heat Pump Water Heater Locations on a Multifamily Floorplan including an interior corridor, eight apartments, and meeting rooms