Showing results 1 - 70 of 70

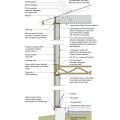

A typical Las Vegas hot-dry climate home made of wood frame construction and insulated with R-25 expanded polystyrene externally over a drainage plane, with an unvented wood frame insulated attic and roof assembly.

Air seal floor joist cavities under kneewall with rigid foam, plywood, or OSB caulked in place

Floor cavity air pressure is measured by placing a tube into the floor cavity through a small drilled hole

Floor cavity pressure is measured by inserting a tube into the floor cavity using an extension pole

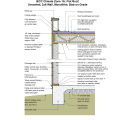

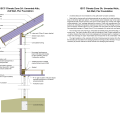

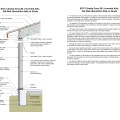

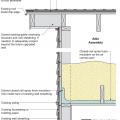

IECC Climate Zone 2A: Unvented Attic with Spray Foam at Roof Deck, 2x6 Wall/CMU Wall, Elevated Slab

IECC Climate Zone 2A: Unvented Attic with Spray Foam at Roof Deck, 2x6 Wall/CMU Wall, Elevated Slab

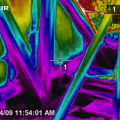

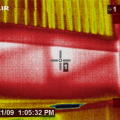

Infrared imaging shows cold conditioned air pouring out of the open floor cavities under this attic kneewall into the hot unconditioned attic

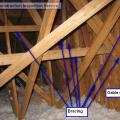

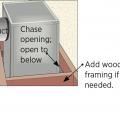

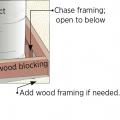

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

One way to air seal and insulate kneewalls – add insulation and a rigid air barrier along roof line of unconditioned attic space outside kneewall

Right - Installation steps for the L-bent strap method of bracing a gable end wall

Right - These attic knee walls are insulated with rigid foam and sealed with spray foam to form a continuous air barrier at the gable end of this cathedral ceiling.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

Right – An existing gable wall is reinforced with horizontal braces that butt up to the gable end wall and connect back to multiple trusses; retrofit studs make full contact with the wall and the compression blocks and are connected to the horizontal brac

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Stuff cavities under kneewalls with rolls of fiberglass batt and spray foam in place

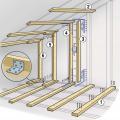

The attic knee walls were constructed from 2x6s and insulated with R-19 batt, backed with 1 inch of XPS foam board with taped joints to provide a solid air barrier over the insulated surfaces.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

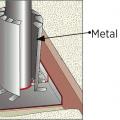

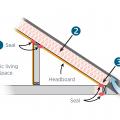

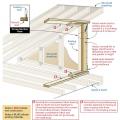

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and a fully adhered membrane seal at the top of wall-to-roof transition

Vented roof assembly at eave retrofitted with rigid foam, spray foam, and fully adhered membrane to air seal the top of wall-to-roof transition

Vented roof assembly at rake retrofitted with spray foam and additional insulation installed at the attic floor and extended to the rake edge

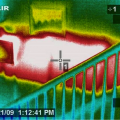

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong – The backing on this knee wall was not air sealed prior to adding insulation.

Wrong – The batt insulation on this knee wall is not properly supported and there is no air sealed rigid backing to provide a solid air barrier.

Wrong – The roof sheathing was inadequately fastened and gave way causing the gable end wall to fail

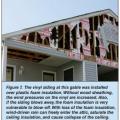

Wrong – The vinyl siding at this gable was installed over plastic foam insulation

Wrong – This gable end wall failed because connectors were missing at points of support (blue circles) and the outlookers were not connected to the end truss (yellow circle)

Wrong – This house under construction is lacking wall to truss bracing and the bottom chord of the scissor trusses is several feet above the top of the end wall top plate

Wrong – This second-story floor plan has red lines that indicate openings from the attic into the interstitial floor space

Wrong: open wall cavity connected to this return air plenum is allowing cellulose attic insulation to be pulled into the furnace

Wrong: This wall cavity is open to the attic allowing unconditioned, attic air to enter the HVAC system, bypassing the filter, and degrading system life and performance