Showing results 351 - 400 of 733

Right - Seam-sealing flashing tape is installed with roller to fully adhere to the OSB.

Right - Seams in coated sheathing and joints around window are properly sealed and flashed with tape and all nail holes are covered with paint-on sealant.

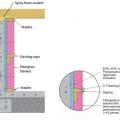

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right - Spray foam insulates and air-seals the stone walls of this unvented crawlspace.

Right - Spray foam insulation air-seals the ceiling-to-drywall seams at the wall top plate.

Right - Spray foam insulation has been sprayed onto the underside of the sloped roof and the gable end wall to provide a sealed, insulated attic for housing the HVAC ducts

Right - The attic access panel is insulated and weather stripped and a dam is built to hold back the blown attic floor insulation

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The seams in the OSB sheathing are sealed with a sprayer-applied sealant.

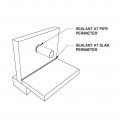

Right - The service penetrations through the structural slab in this garage plenum are air sealed.

Right - The water and air control layers are properly integrated around the hose bib

Right - This ceiling-mounted mini whole-house fan has built-in insulated covers to reduce heat loss when the fan is not in use

Right - This duct penetration is properly flashed and integrated with the taped, foil-faced foam sheathing layer, which serves as the air and water barrier

Right - This opening in the foundation wall around this pipe was filled with wire mesh then sealed with spray foam to prevent rodent and insect entry

Right - Walls and ceilings shared by the garage and living space must be air sealed and insulated.

Right - Wood board sheathing seams are being sealed with low-expanding spray foam.

Right – Attic access hatch has been properly insulated by attaching a fiberglass batt, gasketed, and opening has blocking

Right – A bead of sealant will form an airtight gasket between the top plate and drywall.

Right – A contractor installs mastic in branch duct take offs to air seal the seams where they attach to the trunk duct.

Right – A flexible tape is used to air-seal around wiring holes in the coated sheathing.

Right – A layer of sealant covers the wood-to-foam layer seams in the insulated header.

Right – A strip of foam fabric is installed along the wall top plate to serve as an air sealing gasket when the drywall is installed.

Right – All electrical boxes are carefully sealed as are all top plate-to-drywall seams.

Right – All of the cabinet seams in this HVAC air furnace are sealed with an approved metal tape.

Right – all seams in the rigid foam were sealed with tape before installing the wire lathe for stucco.

Right – An escutcheon is installed on this toilet tank pipe to help air seal around the pipe and prevent pest entry.

Right – An instructor shows students how to caulk the top plates of interior walls.

Right – Apply sealant around penetrations through foundation walls and along foundation wall seams

Right – Attic access door has foam and rubber weatherstripping installed that remains in contact when closed.

Right – Backer-rod is a foam product available in various diameters that can be used to air-seal openings around doors and windows.

Right – Blocking has been installed around the perimeter of this attic access to prevent insulation falling into the house