Showing results 1 - 100 of 149

A 1- and ½-story home with a room located in the attic and the thermal boundary located at either a) the walls and ceiling of the attic room with small vented attic spaces or b) the roof line for an unvented attic

A low-sloped shed roof with the thermal boundary located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

Air leaking through the home's envelope wastes a lot of energy and increases energy costs.

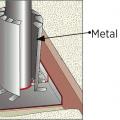

Air seal around all duct shafts and flues installed through ceilings, walls, or flooring to keep conditioned air from leaking into unconditioned space.

Air seal around kitchen and bathroom exhaust fans to keep conditioned air from leaking into unconditioned space.

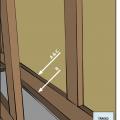

Air seal door and window rough openings with backer rod, caulk, or nonexpanding foam

Air seal the common wall between units in a multifamily structure to minimize air leakage.

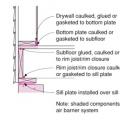

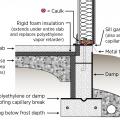

Air-seal above-grade sill plates adjacent to conditioned space to minimize air leakage.

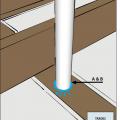

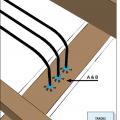

Air-seal around all plumbing and piping installed through walls, ceilings, and flooring adjacent to unconditioned space to prevent air leakage.

Air-seal around all wiring installed through walls, ceilings, and flooring to keep conditioned air from leaking into unconditioned space.

Air-seal around recessed can light fixtures that are installed through ceilings to keep conditioned air from leaking into unconditioned space.

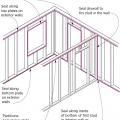

Air-seal drywall to top plates at all attic/wall interfaces to minimize air leakage.

All seams between structural insulated panels (SIPs) foamed and/or taped per manufacturer's instructions

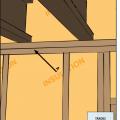

Balloon-framed walls have no top plate to prevent air flow into wall cavity

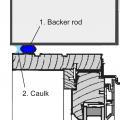

Closed-cell backer rod is installed for air-sealing window and door rough openings.

Fill in the hole left by the missing top plate with a rigid air blocking material or rolled batt insulation that is spray foamed in place

Gaps at shared common walls can be a significant source of air leakage in multi-family buildings

Install a foam gasket along top plates before installing drywall

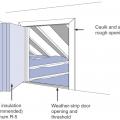

Install an ENERGY STAR labeled insulated door with an automatic closer. Weather strip the door frame

Install continuous top plates or blocking at the tops of walls adjacent to conditioned space to minimize air leakage.

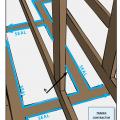

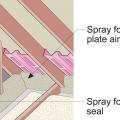

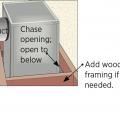

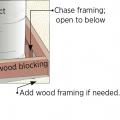

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

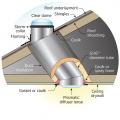

Light tubes adjacent to unconditioned space include lens separating unconditioned and conditioned space and are fully gasketed

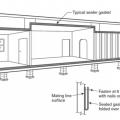

Marriage joints between modular home modules at all exterior boundary conditions fully sealed with gasket and foam

Right - A termite shield and a sill gasket are installed between the sill plate and the foundation on a raised slab foundation.

Right - Gasket installed at marriage wall connection prior to assembling modules

Right - Hole drilled to verify sealant is present - Hole will be sealed after verification

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - The service penetrations through the structural slab in this garage plenum are air sealed.

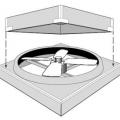

Right - This ceiling-mounted mini whole-house fan has built-in insulated covers to reduce heat loss when the fan is not in use

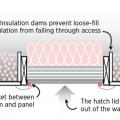

Right – Attic access hatch has been properly insulated by attaching a fiberglass batt, gasketed, and opening has blocking

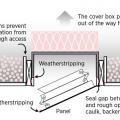

Right – Attic access door has foam and rubber weatherstripping installed that remains in contact when closed.

Right – Backer-rod is a foam product available in various diameters that can be used to air-seal openings around doors and windows.

Right – Blocking has been installed around the perimeter of this attic access to prevent insulation falling into the house

Right – Chase capped with rigid air barrier and duct work penetrations properly sealed

Right – Fan with a cleanly cut and properly sized hole has been air sealed to drywall

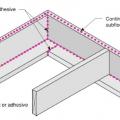

Right – Spray foam was installed at the sheathing intersection as well as the sill plate to sub-floor connection.

Right – The rim joists above the pre-insulated basement walls are sealed and insulated with spray foam to prevent air leakage at this juncture in the building envelope.

Right – The rough opening around the window has been filled with low-expansion foam to air seal.

Right – The rough opening around window has been filled with backer-rod to air seal.

Right – The sill plate was sprayed with foam prior to installation atop foundation.

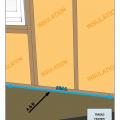

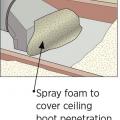

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right – This ICAT recessed light is sprayed with foam to act as gasket against the drywall.

Right – Weatherstripping has been installed and remains in contact when the door is closed.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

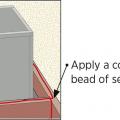

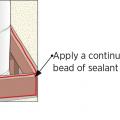

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant along top edge of chase framing

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant on top edge of chase framing

Smoke generators are used to identify air leakage sites during depressurization testing

Spray foam provides a critical seal between the subfloor, rim joist, and sill plate

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation