Showing results 751 - 1000 of 1073

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The attic knee walls were constructed from 2x6s and insulated with R-19 batt, backed with 1 inch of XPS foam board with taped joints to provide a solid air barrier over the insulated surfaces.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The back dam of the window sill will force water out

The batt insulation shown here was properly installed to fill the ceiling cavities.

The brick veneer lacked adequate ties to keep the brick from peeling off the wall in an earthquake.

The builder in this very cold climate installed three layers of unfaced mineral wool batt in the double wall with a code-required vapor barrier between the middle and inner layers of wall insulation that is taped to barriers in the ceiling and floor.

The builder leaves a half inch gap between the exterior and interior walls so drywall can be slid between the two.

The builder staggers 2x4 studs on 2x6 top and bottom plates which provides gaps to fill in insulation around the framing for a continuous blanket of insulation.

The builder was able to pack R-41 of blown fiberglass into the wall cavity formed by the double stud walls.

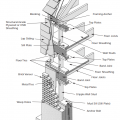

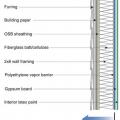

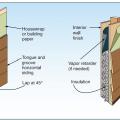

The components of a framed wall include from inside to out: gypsum, wood studs, OSB or plywood sheathing, and siding.

The cripple wall hiding the post-and-pier foundation of this wood framed house toppled when the house was shifted partially off its piers by an earthquake

The cripple walls in this home gave way in the 1994 Northridge Earthquake, causing the walls to partially collapse.

The double walls form a 12-inch cavity that was sheathed with a coated OSB then coated with 3 inches of closed-cell spray foam; they will be filled with 9 inches of blown fiberglass.

The double-wall construction results in thick window sills which builder market as an architectural feature.

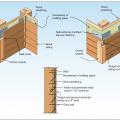

The energy-saving double wall construction uses two side-by-side stud walls, providing an extra-thick wall cavity that can be filled with more than twice as much insulation as a 2x6 wall.

The exterior walls are double walls consisting of two 2x4 stud walls set 3 inches apart to form a 10-inch-thick wall cavity that is filled with blown-in fiberglass to provide a continuous R-40 blanket of insulation around the home.

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

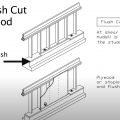

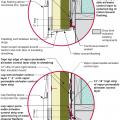

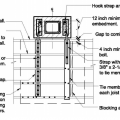

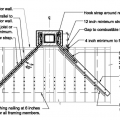

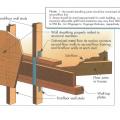

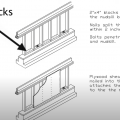

The flush cut method for seismic retrofit bracing of a cripple wall allows the plywood sheathing to be attached directly to both the cripple studs and the notched section of the mudsill

The foam-filled concrete block walls are lined on the interior side with foil-faced rigid foam then topped with furring strips for attaching drywall.

The Habitat affiliate makes its own “ICF” foundation walls with rigid foam held in place with wood spacers.

The home’s first-floor walls are constructed of insulated precast concrete panels that are set in place on a gravel bed.

The I-joist is continuous along the shared wall and serves as a natural air barrier between the garage and the house

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The Larsen-truss 9-inch wall cavities were covered with a smart vapor membrane that was fastened to the trusses with furring strips, which also provide an air gap behind the wood siding; each truss cavity is then filled with blown cellulose.

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The OSB sheathing is coated and taped at the seams to provide a weather-resistant barrier that can take the place of house wrap.

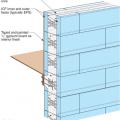

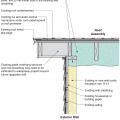

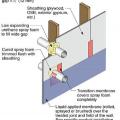

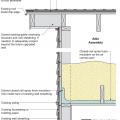

The Perfect Wall includes water, air, thermal, and vapor layers with continuous insulation exterior of the sheathing to reduce the condensation potential in the wall.

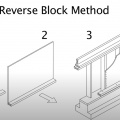

The reverse block method for seismic retrofit bracing of a cripple wall uses a 2x4 attached to the sill plate to provide a means to attach the plywood cripple wall sheathing to the sill plate

The rim band connecting the insulated precast concrete basement walls to the floor joists above is spray foamed to provide air-sealing and insulation in this hard-to-seal juncture.

The rim joists and top plates are air sealed and insulated with open-cell spray foam while the walls are filled with blown fiberglass.

The sheathing has rotted because there was not a sufficient drainage gap behind the stucco cladding

The use of blown-in fiberglass insulation allows the double wall cavity to be filled in completely with no voids that could create cold spots in the walls.

The wall behind the fireplace is an exterior wall and requires a thermal barrier that is continuous with the rest of the wall’s insulation

The wall’s concrete blocks are filled with foam and covered with an interior continuous thermal blanket of rigid foam insulation.

The walls and ceilings of this post-and-beam home are filled with netted blown fiberglass.

The walls and floors of this modular home were constructed in a factory and are brought to the site already insulated and ready for quick assembly.

The walls of this mixed-humid location home are constructed with moisture-resistant steel-framed expanded polystyrene R-34 wall panels that are designed to withstand winds up to 200 mph and level D seismic forces.

The water-resistant barrier, weep screed, and stucco lathe are not properly layered

The water-resistant barrier, weep screed, and stucco lathe are properly layered and will create a complete drainage system

The weep holes are spaced at the correct distance to provide a complete drainage system

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

These factory-built walls consist of 9.5-inch I-studs sheathed with coated OSB, faced with OSB, and dense-packed with cellulose; a second interior surface of drywall is added to provide a 1.5-inch cavity for electrical wiring.

These walls are made of autoclaved aerated concrete blocks that are lightweight, easy to cut, bug-resistant, moisture-resistant, fire-resistant and steel-reinforced to form structurally solid, air-tight, thermally resistant walls.

This 2x6 wall is advanced framed and filled with dense-packed cellulose insulation.

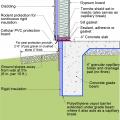

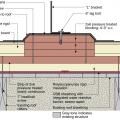

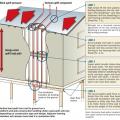

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This building has a south facing Trombe wall to take advantage of passive solar heating.

This close-up of an exterior wall retrofit of a masonry brick home shows the fluid-applied water and air control layer (white), 2x4 furring strips and two layers of rigid foam insulation (pink), then 1x4 furring which provides a ventilation gap

This coastal home was built on a flood-resistant pier foundation using hurricane- and moisture-resistant expanded polystyrene and steel wall panels and hurricane strapping.

This community of production homes in central New York state was built with insulated concrete forms (ICFs), which provide a highly insulated, airtight structure that is fire-, pest-, wind-, and earthquake-resistant.

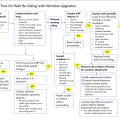

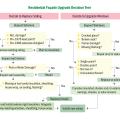

This detailed decision tree can help homeowners and contractors make decisions about re-siding a home and upgrading windows

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

This farmhouse was retrofit by removing the existing siding and adding taped insulated sheathing and battens before installing new siding

This fiberglass batt insulation has a kraft paper facing that is correctly stapled to the face rather than the sides of the wall studs to minimize compression.

This flood-resistant exterior wall with brick or fiber-cement siding will limit moisture damage in exterior walls.

This flood-resistant masonry wall design with metal framing and rigid foam insulation will limit moisture damage in exterior walls.

This foundation/floor/SIP wall detail shows recommended support of SIP wall panel at the sill plate

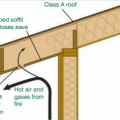

This home has heat loss through the roof, leading to ice dam formation and structural issues during winter months.

This home uses light-colored standard paints and finishes on siding and roofing materials to reduce cooling loads without adding material cost.

This home’s 2x6 advanced framed walls are insulated and air sealed with 3 inches of closed-cell spray foam.

This home’s double-wall construction provides a 9-inch wall cavity for insulation.

This home’s exterior walls consist of two 2x4 walls; the R-49 double wall cavity is filled with 2 inches of closed-cell spray foam plus dense-packed cellulose.

This home’s exterior walls include Larsen trusses, 9-inch I-joists attached through exterior sheathing to wall studs creating a 9-inch wall cavity that was filled with blown insulation and forms extra deep windowsills.

This hot climate zone home uses high quality batt insulation between studs to insulate this connecting garage wall.

This hot climate zone home uses high quality batt insulation to insulate truss-joist headers.

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

This house is being built with advanced framing techniques including 2x6 24-inch on-center wall framing

This house is sited so the existing trees will shade the west-facing walls to minimize summertime heat gain

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

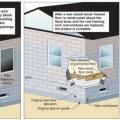

This left-to-right sequence shows the method of wall extension to flood-proof a masonry house on a slab foundation. Here the new, raised floor is wood-framed over a wet-floodproofed crawlspace, but using fill to create a new raised slab is also an option.

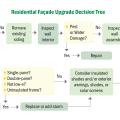

This simple decision tree can help homeowners and contractors determine options about wall and window upgrades when re-siding a home

This simple decision tree can help homeowners and contractors make decisions about re-siding a home and upgrading windows

This simple decision tree can help homeowners and contractors make decisions about wall and window upgrades when re-siding a home

This simplified decision tree can help a homeowner or contractor assess how appropriate a cool roof or wall will be for a particular home

This technique for installing electrical wiring avoids the need to cut into the SIP panel

This unfaced fiberglass completely fills the wall cavities, with RESNET Grade 1 insulation.

This wall and window assembly has excessive framing around the windows, which can lead to heat gain in how climate zones.

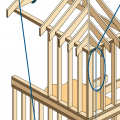

This wood-framed wall is connected with framing anchors, metal strapping and ties, and anchor bolts to secure the roof to the walls and walls to the foundation

Thorough air sealing is one way the Habitat for Humanity affiliate in Loudon County, FL, improves the efficiency and weather resistance of its homes.

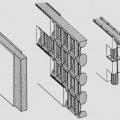

Three common ICF wall systems: the flat wall, the waffle wall, and the post-and-beam wall

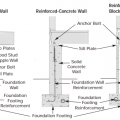

Three types of foundation walls: Stem-plus-wood stud cripple wall, reinforced concrete wall, and reinforced concrete block/masonry wall

To ensure a complete air barrier between the garage and the house, the wall between the garage and the house was insulated and air-sealed with four inches of high-density spray foam.

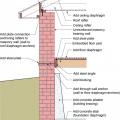

To increase a masonry-walled home’s resistance to seismic forces, solid wood blocking is added between the roof rafters, anchors are added to connect the brick wall to the rafters and floor joists, building diaphragms are added, foundation braced

To keep chase width to a minimum, use flat sheet metal as opposed to a collar and flex duct for supplies into rooms where the chase is located

Top view showing how the chimney is attached to at least four ceiling joists running parallel to the exterior wall.

Top view showing how the chimney is attached to ceiling joists that run perpendicular to the exterior wall.

Two layers of high-permeability house wrap are installed to provide a drainage layer between the SIPS and the homes external cladding

Two layers of XPS are installed with staggered seams over a liquid-applied membrane on the structural sheathing

Unfaced batt and blown fiberglass wall insulation are installed to RESENET Grade 1 standards with no gaps or voids.

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and a fully adhered membrane seal at the top of wall-to-roof transition

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and taped top edge of existing house wrap or building paper

Unvented roof assembly at rake retrofitted with spray foam installed along the underside of the roof deck and extended to the rake edge to insulate and air seal the attic

Uplift forces acting on the roof are met with roof-wall connections that distribute the forces down the walls and into the foundation along the continuous load path.

Upper-floor tie to lower floor for two-story building. Floor tie anchor and nailed wall sheathing.

Use a smoke pencil to check for air leaks at SIP panel seams, especially along the ridge beam

Use a truss joist header assembly as shown here to reduce thermal bridging in hot climate zones.

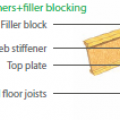

Use caulk or spray foam to air-seal all four edges of the blocking material in each joist bay.

Use flashing tape to seal around any pipes or vents that penetrate through the foam

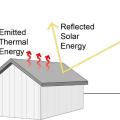

Using roof and wall materials with a high Solar Reflectance Index (SRI) will reduce heat gains.

Utilities are commonly recessed into cutouts in the foam after concrete has been poured

Vapor-permeable mineral wool insulation is installed on the exterior side of the sill beam during an exterior wall retrofit to allow the sill beam to dry to the outside

Vented roof assembly at eave retrofitted with rigid foam, spray foam, and fully adhered membrane to air seal the top of wall-to-roof transition

Vented roof assembly at rake retrofitted with spray foam and additional insulation installed at the attic floor and extended to the rake edge

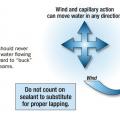

Wall surfaces having high solar reflectance and high thermal emittance will remain cooler when exposed to direct sunlight.

Walls are being assembled at this SIP house

Walls in cold climates with a Class 3 vapor retarder (latex paint) and a vapor-open continuous insulation like mineral wool allow drying to the interior or the exterior

Walls in cold climates with a polyethylene vapor barrier interior of the wall cavity should have either no exterior insulation or a vapor-open continuous insulation like mineral wool that allows drying to the exterior

Water management detail for a solar panel rack mounting block installed in rigid foam that was installed over an existing roof

Weep holes: Rope inserted in the head joist between bricks will allow water to weep out of the base of the wall assembly

Wet Floodproofing Equal Rates of Rise and Fall to Eliminate Hydrostatic Pressure Differences

When moisture is trapped inside walls, mold can grow unchecked, causing damage to the walls and health impacts for the occupants.

When using I-joists, make sure to fill in the gaps on each side of the blocking material to air-seal the joist bay where a wall separates conditioned and unconditioned spaces.

White walls and roofs; overhangs and awnings; and operable shutters and garden walls all help to keep out unwanted solar heat gain providing cool interiors for this Florida home.

Window and door rough openings in the ICF wall are surrounded with pressure-treated wood

Windows are installed in new framing in preparation for adding exterior spray foam insulation

Windows are sized and positioned so only one king stud is needed on each side of the window.

Wiring runs are covered with canned spray foam to maintain the continuous foam layer that covers the inside and outside of these ICF block walls.

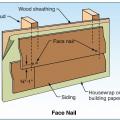

With fiber cement siding, face nail rather than blind nail where the design wind speed is ≥100 mph.

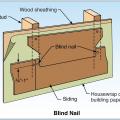

With fiber cement siding, place blind nails 3/4 to 1 inch from top edge and > 3/8 inch in from butt ends.

With the nailed block method, wood blocks are attached to the sill plate and the cripple wall plywood is attached to the block to provide shear strength for correctly bracing a cripple wall in a seismic retrofit

Wood siding installation details to improve resistance to wind-driven rain at corners.

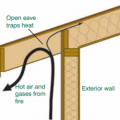

Wrong - An open eave with no soffit covering can trap rising hot air and embers from a wildfire.

Wrong - Board is not properly cut and is split where it is toenailed into top plate.

Wrong - Continuous rigid insulation was not installed to continuously cover the sheathing.

Wrong - Craft faced batt insulation is not cut to fit around wiring and eletrical boxes and is squished into corners forming voids which could encourage cold spots in wall.

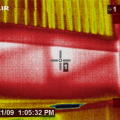

Wrong - Dark pattern on wall is showing where warm air is leaking into the wall cavity from interior of home.

Wrong - Dark patterns on the Home's exterior siding show where warm air is leaking into the wall cavities.

Wrong - During high winds air entered the home elsewhere and pushed out the door which was inadequately anchored to the wall.

Wrong - Framing a dormer using only toe nailing and end nailing is not acceptable in areas subjected to high winds, hurricanes, or earthquakes.

Wrong - House wrap was not properly cut and adhered where the roof meets the wall so water is likely to get behind the house wrap.

Wrong - House wrap was poorly cut at wall interface and not taped leaving wood exposed and vulnerable to water entry.

Wrong - If the soffit is applied directly to the rafter eave, it forms a sloping soffit, which creates a pocket that can trap hot air and embers from a wildfire.

Wrong - Lack of a weather-resistant barrier allowed water to get behind the siding and rot the framing in this corner rim joist area.

Wrong - Lack of house wrap or weather resistant barrier lead to significant water damage behind the brick veneer.

Wrong - Metal flashing is bent and poorly installed and tape flashing is missing.

Wrong - Rigid insulation blocking is installed but not air-sealed with spray foam around edges.

Wrong - Roof is missing metal drip edge to cover the edge of OSB roof decking, roof underlayment should be trimmed back, and asphalt shingles are poorly installed.

Wrong - Roof-wall juncture lacks metal flashing and is poorly designed, thus encouraging water entry.

Wrong - Stucco has rotted and cracked above a window because of water damage due to lack of proper flashing and drainage.

Wrong - The air barrier is not sealed (picture taken from garage looking into house).

Wrong - The below-grade concrete does not have the correct construction to be impermeable to moisture because the lumber is untreated and against the concrete that lacks waterproofing.

Wrong - The caulk is too far from the sill plate to effectively air-seal the gap.

Wrong - The faced batt insulation does not provide an air barrier in the joist bay between the garage and the conditioned space of the home.

Wrong - The studs added for support were cut at an angle providing weak support where the stud meets the compression block.

Wrong - this building provides no overhangs, minimal window shading, and clear window glass resulting in high solar heat gain.

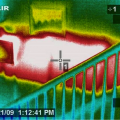

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong - This is a poorly sealed chase with no solid air barriers along the sides of the chase and no caulk around the electrical wires installed through the ceiling of the chase.

Wrong - Through-wall flashing has not been installed at brick wall intervals and house wrap is missing.

Wrong - Unfaced fiberglass batt is not properly cut to fit in all the stud bays.

Wrong - Utility trim was substituted for the starter strip and the bottom lock was cut off this vinyl siding so the siding pulled loose under wind pressure.

Wrong - Vinyl siding in incorrectly installed under not over door trim and door trim channel pieces are missing.

Wrong - Wall cavities behind shower are not completely filled with insulation and are lacking the solid interior air barrier.

Wrong - When ceiling joists over a garage run perpendicular to the adjoining wall, the joist bays must be blocked and sealed to prevent garage fumes from entering the living space

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – An opportunity to use structural members as a natural air barrier was missed in this home and blocking was not initially planned for between the garage and living space.

Wrong – Building materials are being stored outdoors with no protection from weather

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen

Wrong – Design walls so that windows are positioned to fit regularly spaced studs so less additional studs are needed.

Wrong – Either this tape was not pressed down firmly or the surface was wet or dirty so the tape is not sticking properly even during construction.

Wrong – Foam was sprayed at exterior sheathing and sill plate connection, leaving gaps beneath sill plate.

Wrong – For proper detailing of vinyl around windows and other obstacles, use utility trim, punch snaplocks into siding, and do not overlap directly beneath a window.

Wrong – If dimpled plastic is used it should be trimmed to drain down at the bottom rather than up where water can collect in it.

Wrong – If the insulated sheathing will serve as an air barrier and drainage plane, any cuts and seams must be taped or sealed.

Wrong – Insulation does not fill entire cavity nor is there an air barrier present between the double wall