Showing results 101 - 200 of 1073

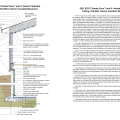

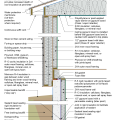

2021 IECC Climate Zone 6B: Vented Over-Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

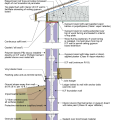

2021 IECC Climate Zone 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement (with notes)

2021 IECC Climate Zones 7 and 8: Vented Attic, 2x4 Wall, Interior Insulated Basement

2021 IECC Climate Zones 7 and 8: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zones 7 and 8: Vented Attic, ICF Wall, ICF Basement Foundation

2021 IECC Climate Zones 7 and 8: Vented Attic, Interior Double Wall, Interior Insulated Basement

2021 IECC Climate Zones 7 and 8: Vented Attic, Strapped 2x6, Interior Insulated Basement

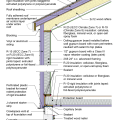

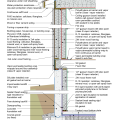

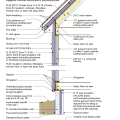

2021 IECC Climate Zones 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

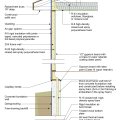

2021 IECC Climate Zones 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Slab on Grade

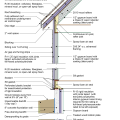

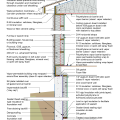

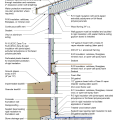

2021 IECC Climate Zones 7 and 8: Vented Over-Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

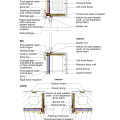

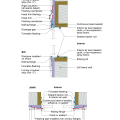

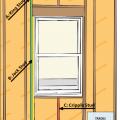

2021 IECC Window Detail: Double Wall Framed with Plywood or OSB Sheathing, a WRB, and Siding (Wood, Fiber Cement, Aluminum, or Vinyl)

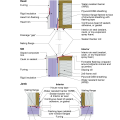

2021 IECC Window Detail: Framed Wall with a WRB, Rigid Insulation, and Siding (Wood, Fiber Cement, Aluminum or Vinyl) or Stucco

2021 IECC Window Detail: Framed Wall with Plywood or OSB Sheathing, a WRB, and Siding (Wood, Fiber Cement, Aluminum or Vinyl, or Stucco)

2021 IECC Window Detail: Framed Wall with Plywood or OSB Sheathing, a WRB, Thick Rigid Insulation, and Siding (Wood, Fiber Cement, Aluminum or Vinyl)

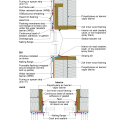

2021 IECC Window Detail: Framed Wall with Rigid Insulation and Siding (Wood, Fiber Cement, Aluminum or Vinyl)

2021 IECC Window Detail: Framed Wall with Thick Rigid Insulation and Siding (Wood, Fiber Cement, Aluminum or Vinyl)

2021 IECC Window Detail: Strapped 2x6 Framed Wall with Plywood or OSB Sheathing, a WRB and Siding (Wood, Fiber Cement, Aluminum or Vinyl)

A builder, energy efficiency consultant, and crew supervisor inspect a spray foam installation.

A coated OSB product with taped seams covers the walls to serve as both sheathing and weather-resistant barrier.

A continuous layer of polyethylene covers the crawlspace floor and is attached to the wall with wood nailing strips

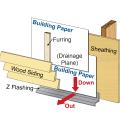

A drainage plane is created behind lap siding by installing furring strips on the exterior walls over house wrap which is overlapped and taped at all seams to serve as an air and water barrier.

A gut rehab that includes drywall removal provides the opportunity to thoroughly insulate the walls.

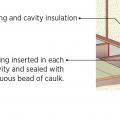

A large bead of caulk is installed on the interior surface of the wall top and bottom plates to provide an air sealing gasket between the framing and the dry wall.

A moisture meter verifies that the moisture of the framing is below the recommended 18%.

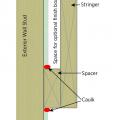

A piece of siding is used as sill extension and to provide slope in the opening for the window, which is deeper because exterior rigid foam has been added

A plastic fiber drainage mat rainscreen provides uniform support for the siding and allows moisture to flow horizontally and diagonally in addition to vertically.

A raised wood pier foundation can raise the subfloor above the design flood elevation.

A self-adhering weather-resistant barrier is installed over the existing sheathing of this retrofit home to provide air sealing and a drainage plane before installing new metal and wood siding on the home.

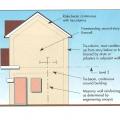

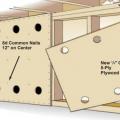

A single-story house floor plan showing braced wall line locations at A through E and 1 through 5

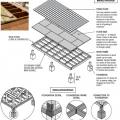

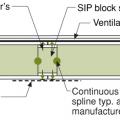

A structural spline made of a solid 2x is used where needed to meet structural load requirements at SIP panel seams

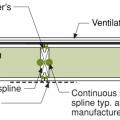

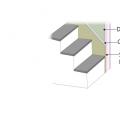

A surface spline reduces thermal bridging much more than a structural spline at SIP panel seams

A typical Las Vegas hot-dry climate home made of wood frame construction and insulated with R-25 expanded polystyrene externally over a drainage plane, with an unvented wood frame insulated attic and roof assembly.

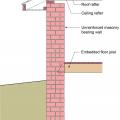

A typical older masonry home with unreinforced brick walls, wood floors, and a wood roof

A wall assembly approved for use in the wildland-urban interface has 5/8-inch type X gypsum installed exterior of the wood sheathing and an exterior covering or siding that has a 1-hour fire-resistance rating

Add metal connectors to strengthen framing connections in an existing wall from inside the home by removing drywall.

Adding air-sealing and rigid foam insulation at the wall-to-overhanging floor juncture at the outside corner of an existing home

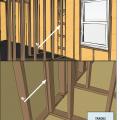

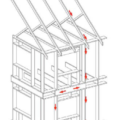

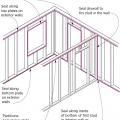

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

Advanced framing details include open headers and reduced framing around windows and two-stud corners to allow more room for insulation in the wall cavities while reducing lumber costs.

Advanced framing details include using the minimum amount of wall studs permitted by code.

Advanced framing details throughout house limit use of lumber and makes space for bonus insulation.

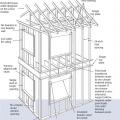

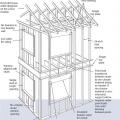

Advanced framing techniques include constructing on a 2-foot grid where wall studs are placed 24 inches on center and aligned with roof and floor trusses for a continuous load path from roof to foundation.

Advanced framing techniques including 2x6 walls spaced at 24 inches on center and ladder blocking at wall intersections allow more space for insulation in the wall cavities while open-web floor joists provide space between floors for ducting.

After attaching netting to the 2x6 studs, workers fill the wall cavities with R-23 of blown fiberglass made from recycled bottles.

After spraying the 2x6 wall cavities with 2 inches (R-13) of closed-cell spray foam, the walls are covered with netting and an additional 3.5 inches of fiberglass (R-13) is blown in.

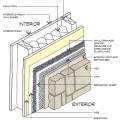

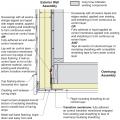

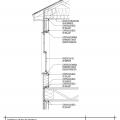

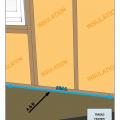

Air barrier is continuous across several components of the lower section of wall

Air seal and insulate double-walls that are half-height or full-height walls used as architectural features in homes.

Air seal floor joist cavities under kneewall with rigid foam, plywood, or OSB caulked in place

Air seal the common wall between units in a multifamily structure to minimize air leakage.

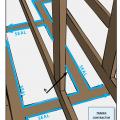

Air-seal above-grade sill plates adjacent to conditioned space to minimize air leakage.

Air-seal drywall to top plates at all attic/wall interfaces to minimize air leakage.

An all-terrain forklift is used to move and stage the panels

An exterior wall braced using the let-in-bracing (LIB) method with no exterior sheathing

An installer fills these wall cavities with spray foam insulation, which will be trimmed flush with the stud faces after it dries and hardens.

An insulated spline is another option for avoiding thermal bridging at SIP panel seams

Angle support framing is added to brace a long gable overhang constructed using the ladder framing method.

Apply self-adhesive flashing over top edge of the wall flashing, diverter, and housewrap

Attach the interior 2x4 wall to the exterior wall top plate with a flat metal connector plate

Baffles will keep insulation out of the soffit vents and wind out of the insulation in this vented attic.

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

Bees made a nest in the drainage plane behind a brick veneer wall by entering via unscreened weep holes

Before installing the windows, the window rough openings are sealed with a liquid-applied flashing that provides a seamless moisture and air barrier to protect the wall from water intrusion.

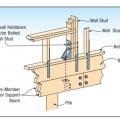

Braced cripple wall construction in crawlspace anchored to framing and foundation

Brick veneer framed wall supported by a concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

Brick veneer is supported by a concrete stem wall thermally separated from the slab-on-grade foundation with turn-down footing which is also insulated on top; anchorage for seismic resistance is also shown

Brick wall assembly for a hot-humid climate with no Class I vapor retarder and with an air gap (drained cavity) to dissipate vapor driven into the wall by the sun.

Building America worked with Mercedes Homes in east Florida to design homes using cast-in-place concrete walls capable of withstanding wind-blown debris impacts of up to 200 mph (Source: Mercedes Homes).

Buildings damaged by a hurricane storm surge: upper homes on gulf shoreline were hit by large waves above the lowest floor, lower left home on bay and right school 1.3 miles from gulf shoreline were hit by surge and small waves.

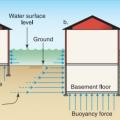

Buoyancy force on dry floodproofed homes with deep basements leads to possible foundation damage

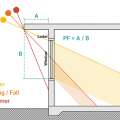

Calculate projection factor (PF) by dividing overhang (A) by length of window (B).

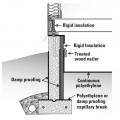

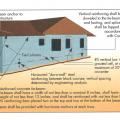

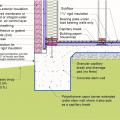

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and lapped up each wall or pier and fastened with furring strips or equivalent