Showing results 1 - 117 of 117

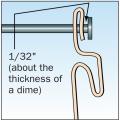

A plastic fiber drainage mat rainscreen provides uniform support for the siding and allows moisture to flow horizontally and diagonally in addition to vertically.

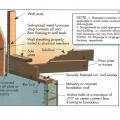

A raised wood pier foundation can raise the subfloor above the design flood elevation.

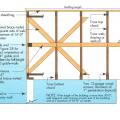

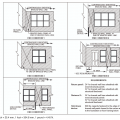

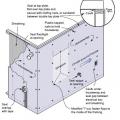

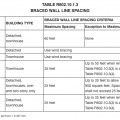

A single-story house floor plan showing braced wall line locations at A through E and 1 through 5

Add metal connectors to strengthen framing connections in an existing wall from inside the home by removing drywall.

Building America worked with Mercedes Homes in east Florida to design homes using cast-in-place concrete walls capable of withstanding wind-blown debris impacts of up to 200 mph (Source: Mercedes Homes).

Buildings damaged by a hurricane storm surge: upper homes on gulf shoreline were hit by large waves above the lowest floor, lower left home on bay and right school 1.3 miles from gulf shoreline were hit by surge and small waves.

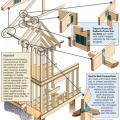

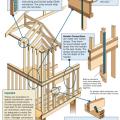

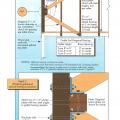

Connecting hardware helps tie the roof to the walls to ensure a continuous load path to improve a building’s resistance to high winds, floods, and earthquakes.

Connecting hardware helps tie the walls to the top plates and rim joists to ensure a continuous load path to improve a building’s resistance to high winds, floods, and earthquakes.

Correct seismic retrofit hardware for securing the sill plate to foundation wall

Durability concerns on a house continuously sheathed with a proprietary fiber structural panel used as bracing. Photo 1 of 2.

Durability concerns on a house continuously sheathed with a proprietary fiber structural panel used as bracing. Photo 2 of 2.

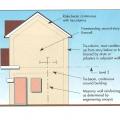

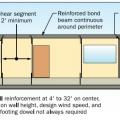

End conditions for braced wall lines with continuous sheathing, Figure R602.10.7 in the IRC

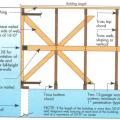

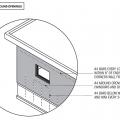

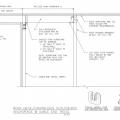

Example A of a gable truss and gable end wall bracing for a home in a hurricane region

Example B of a gable truss and gable end wall bracing for a home in a hurricane region

Example of masonry construction. Wall separated from building envelope due to inadequate vertical wall reinforcing in connection to horizontal tie-beam.

Failure of a freestanding concrete masonry end wall due to discontinuous tie-beam when exposed to hurricane force winds.

Firewall separation. Results from building corners being discontinuous with tie-beams.

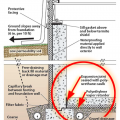

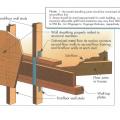

Good water management practices like sloping grade away from house, and installing gutters, perimeter drain pipe, a capillary break, and free-draining soils or drainage mat protect the foundation from water saturation.

House wrap is sealed at all seams and overlaps flashing to serve as a continuous drainage plane over the exterior walls.

Hurricane force winds that breach external windows and doors can then cause failure of the entire building due to internal pressures on walls and roof.

Hurricane straps, hold-down connectors, and bolts help to transfer loads from the building’s walls to its foundation, increasing resistance to vertical and horizontal pressures acting on the building from wind, waves, or ground movement.

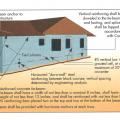

Improper continuous load path design lacking bracing results in the failure of gable end walls under high wind conditions.

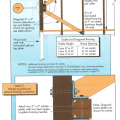

In areas prone to high winds and hurricanes, double vertical “jack trim” and horizontal “header” and “sill” studs are recommended on all sides of window and door openings.

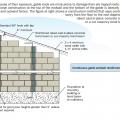

In high wind areas, provide lateral support to masonry end walls to resist high winds.

In high-wind regions, special hardware is used for most framing connections; toe-nailing is not acceptable.

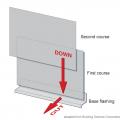

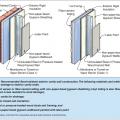

Install all layers of the drainage plane to overlap, not underlap, to direct bulk water down and out of the wall.

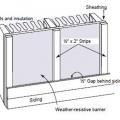

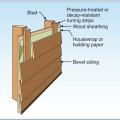

Install furring strips over house wrap to provide a rainscreen behind wood siding.

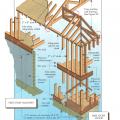

Key connection points for a continuous load path for earthquake and high wind disaster resistance

Lower-story wall anchorage to masonry (or concrete) base. Straps properly nailed at wall studs.

Moisture-resistant plastic and fiber cement exterior trim and cladding are indistinguishable from wood building elements.

Properly reinforce masonry walls in coastal locations to resist high winds and waves.

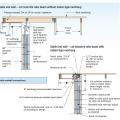

Recommended flood resistant wall construction for concrete block walls with stucco or brick veneer.

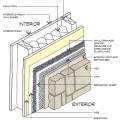

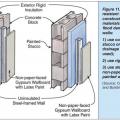

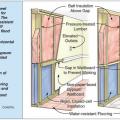

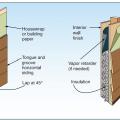

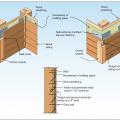

Redundant moisture barriers including siding, house wrap, and coated sheathing can help protect walls from excess moisture, while vapor retarders prevent vapor from entering the wall from the house, for example from a bathroom or kitchen.

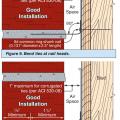

Right – The ties are bent at a 90 degree angle at the nail head and embedded into the mortar joint at least 1.5 inches.

Right - A continuous load path connects the roof and wall framing to the foundation.

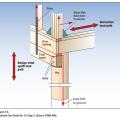

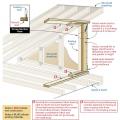

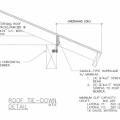

Right - Anchorage to increase the wind uplift resistance of outlookers forming the overhang at a gable end truss wall.

Right - Braced wall line spacing is correctly calculated for determining wall bracing in accordance with the IRC.

Right - Engineered portal frames are used for wall bracing to resist wind and earthquake loads.

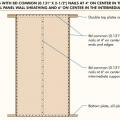

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

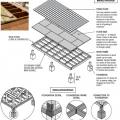

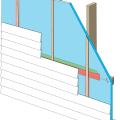

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – The building felt is installed on all exterior walls and provides a complete drainage system

Right – The rigid insulation covers all exterior walls and all seams are taped to provide a complete drainage system

Right – The water-resistant barrier covers the entire house and the seams are taped to provide a complete drainage system

Right – This low-slope roof and parapet assembly has continuity of both the air and water barriers

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

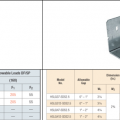

Shear Strength Comparison Between a Foundation Stud Anchor (on left) and a Shear Transfer Angle (on right)

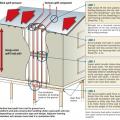

Step 1. Remove the existing wall cladding to prepare to retrofit an exterior wall.

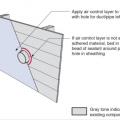

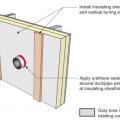

Step 2. Install a continuous air and water control layer over the existing wall sheathing.

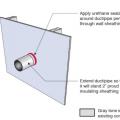

Step 3. Apply urethane sealant around the duct or pipe in the retrofitted exterior wall.

Step 4. Install insulating sheathing and vertical furring strips on the retrofitted exterior wall; seal around pipe or duct with urethane sealant.

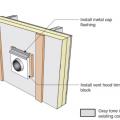

Step 5. Install sheathing tape flashing over the duct or pipe and wood blocking on either side for later attachment of trim.

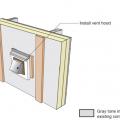

Step 6. Install vent hood trim block, metal cap flashing; seal top edge of flashing with sheathing tape.

Step 8. Attach the new cladding to the furring strips over the rigid foam for the exterior wall retrofit.

The components of a framed wall include from inside to out: gypsum, wood studs, OSB or plywood sheathing, and siding.

The sheathing has rotted because there was not a sufficient drainage gap behind the stucco cladding

Upper-floor tie to lower floor for two-story building. Floor tie anchor and nailed wall sheathing.

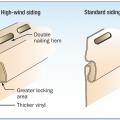

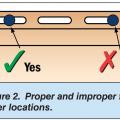

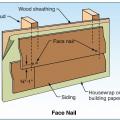

With fiber cement siding, face nail rather than blind nail where the design wind speed is ≥100 mph.

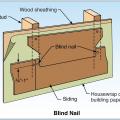

With fiber cement siding, place blind nails 3/4 to 1 inch from top edge and > 3/8 inch in from butt ends.

Wood siding installation details to improve resistance to wind-driven rain at corners.

Wrong - During high winds air entered the home elsewhere and pushed out the door which was inadequately anchored to the wall.

Wrong - Framing a dormer using only toe nailing and end nailing is not acceptable in areas subjected to high winds, hurricanes, or earthquakes.

Wrong - Utility trim was substituted for the starter strip and the bottom lock was cut off this vinyl siding so the siding pulled loose under wind pressure.

Wrong – For proper detailing of vinyl around windows and other obstacles, use utility trim, punch snaplocks into siding, and do not overlap directly beneath a window.

Wrong – Misalignment of the tie reduces the embedment and enables the brick veneer to be pulled away.

Wrong – The rigid sheathing seams are not taped and the gaps could cause moisture problems

Wrong – The roof sheathing was inadequately fastened and gave way causing the gable end wall to fail

Wrong – The underside of the first course of siding extends beyond the underlying sheathing leaving it vulnerable being pulled off by pressure from high winds.

Wrong – The vinyl siding at this gable was installed over rigid foam instead of wood sheathing and neither had the structural strength to resist hurricane wind pressures.

Wrong – The water-resistant barrier is not complete and the holes and gaps could cause moisture problems

Wrong – There is not a water-resistant barrier installed underneath the exterior finish of the walls

Wrong – These four ties were never embedded into the mortar joint, allowing the brick wall to be pulled away from the sheathing.

Wrong – This brick veneer failed in high winds (107 mph) because the ties pulled out of the substrate.

Wrong – This gable end wall failed because connectors were missing at points of support (blue circles) and the outlookers were not connected to the end truss (yellow circle)

Wrong – This metal tie remained embedded in the mortar joint but the smooth-shank nail pulled out from the stud.