Showing results 1 - 100 of 141

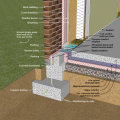

Impervious surfaces like patio slabs, sidewalks, and driveways that are within 10 feet of the home should slope away from the house.

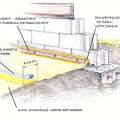

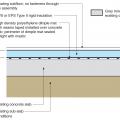

A concrete slab floor can be elevated above local grade as a strategy to prevent flood damage.

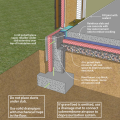

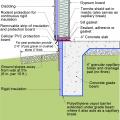

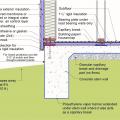

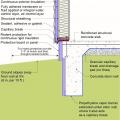

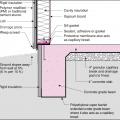

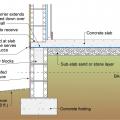

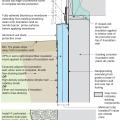

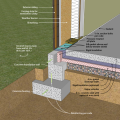

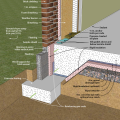

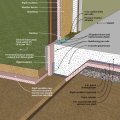

A concrete slab-on-grade foundation with exterior insulation, which can be elevated above the local grade as a flood-prevention strategy.

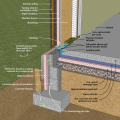

A layer of pea gravel or crushed stone, 4 inches thick and sloped 5%, provides a pest-resistant ground break around the perimeter of a slab foundation

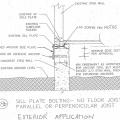

An anchor side plate is used to connect the concrete foundation to the sill plate from the exterior as part of a seismic retrofit when the sill plate is not accessible from the interior of the home

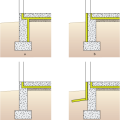

An externally insulated slab-on-grade is pest-protected by a metal termite shield under sill plate, metal-flashing-wrapped foam under siding, a removable inspection strip of PVC-covered foam, and 2 feet of gravel next to the foundation.

An uninsulated (or existing insulated) basement slab is retrofitted to reduce moisture transmission by sealing with epoxy paint.

Any holes through the vapor barrier installed over the basement floor slab are thoroughly sealed as part of the foundation water barrier system.

Between the ICF foundation walls, the builder sprayed closed-cell spray foam directly onto the gravel base to provide a vapor barrier and continuous layer of insulation under the slab.

Brick veneer framed wall supported by a concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

Brick veneer is supported by a concrete stem wall thermally separated from the slab-on-grade foundation with turn-down footing which is also insulated on top; anchorage for seismic resistance is also shown

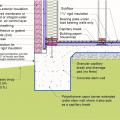

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and placed beneath a concrete slab

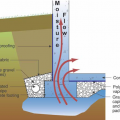

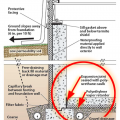

Capillary break beneath all slabs (e.g., slab on grade, basement slab) except crawlspace slabs using either: ≥ 6 mil polyethylene sheeting lapped 6-12 in., or ≥ 1 in. extruded polystyrene insulation with taped joints

Comprehensive water management features include a capillary break (≥ 6-mil polyethylene sheeting) at all crawlspace floors

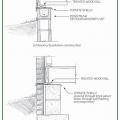

Concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

Epoxy paint is installed to provide a moisture control layer on the surface of an existing basement slab

Externally insulated concrete slab-on-grade foundation with a turn-down footing, showing anchorage of the wall to the foundation for seismic resistance

Externally insulated post-tensioned concrete slab-on-grade foundation wall with a turn-down footing showing anchorage of the wall to the foundation for seismic resistance

Externally insulated post-tensioned concrete slab-on-grade foundation wall with a turn-down footing showing anchorage of the wall to the foundation for seismic resistance

For slabs on grade in CZ 4 and higher, 100% of slab edge insulated to ≥ R-5 at the depth specified by the 2009 IECC and aligned with thermal boundary of the walls

Four inches of rigid foam separate the concrete slab from the ground and the foundation walls.

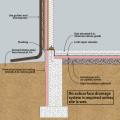

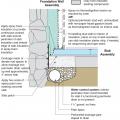

Good water management practices like sloping grade away from house, and installing gutters, perimeter drain pipe, a capillary break, and free-draining soils or drainage mat protect the foundation from water saturation.

Hot water recirculation loop runs through an insulated pipe under the home’s concrete slab.

ICF foundation walls wrap the floor slab in R-22 of insulation while the entire space under the slab is covered with 4.3 inches of closed-cell spray foam.

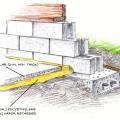

Install termite shields and use solid concrete or filled concrete block for the top of foundation walls to deter termites and other pests

Patio slabs, porch slabs, walks, and driveways sloped ≥ 0.25 in. per ft. away from home to edge of surface, or 10 ft., whichever is less

Pest protection measures include a termite shield under the rim joist and extending out on either side of the stem wall, insect screening under the furring air gap, and brick veneer to protect slab-edge insulation.

PEX piping is laid over 2 inches of XPS before the slab is poured to create a radiant floor heating system in this extensive home remodel.

PEX piping loops are laid before the slab is poured for this radiant floor heating system

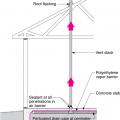

Raised-slab CMU foundation including flood-resistant features: sloped grade, damp proofed stem wall, capillary break under the slab (gravel or sand), vapor barrier under the slab and capillary break at the top of the foundation wall (polyethylene sheet)

Reinforce concrete slab and foundation walls to minimize future cracks that could let in pests

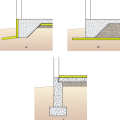

Right - Additional potential locations for slab-on-grade insulation include (a) under the slab and outside the perimeter with optional underground moisture block, (b) under the whole foundation, or (c) on top of the slab.

Right - Basement slab with a capillary break of either gravel or a drainage mat.

Right - Potential locations for slab-on-grade stem insulation in new construction: slab insulation should always be underneath, with stem walls insulated (a) inside, (b) outside, (c) not at all, or (d) outside with underground extension to repel moisture.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

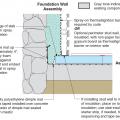

Right - Rigid foam is installed over a waterproofing membrane that has been applied to the basement foundation walls.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

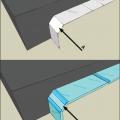

Right - This rigid insulation is correctly installed in a level layer over aggregate; the seams will be taped

Right - Workers installed rigid foam on the floor and the sill plates of these pre-cast, pre-insulated concrete wall panels to provide a continuous layer of insulation under and around the not-yet-poured basement floor slab.

Right – After installing the insulated concrete foundation wall panels, the builder installed underslab rigid foam, which was topped by 4 inches of crushed rock then the poured slab.

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – Polyethylene sheeting completely covers the aggregate and the footing with no tears or open seams

Right – Polyethylene sheeting is laid over aggregate and over footing to provide a capillary break between the ground and the slab and between the footing and the stem wall

Right – R-20 of XPS and polyiso rigid foam were added on the slab shelf that is part of this precast foundation wall system.

Right – Rigid foam was attached to the tops of the precast foundation walls to form an insulated edge for the floor slab.

Right – The drain slopes away from the foundation and terminates at the proper distance

Right – The foundation of this ICF home was constructed of ICFs that were set in place on a gravel bed, then 3.5 inches (R-36) of closed-cell spray foam was sprayed directly onto the gravel, providing an effective air, vapor, and thermal barrier.

Right – The raised-slab, brick-and-block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, CMU block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, poured-concrete stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The seam between the slab and the foundation wall is sealed with urethane caulk.

Right – The slab is coated with two coats of epoxy paint to minimize moisture transfer through the slab from the ground.

Right – This wall is constructed with the sill plate overhanging the top of the foundation wall so that when rigid foam is installed on the exterior of the foundation wall, its surface will align with the surface of the wall sheathing.

Right – Workers lay radiant floor loops over the concrete reinforcement which is laid over a heavy vapor barrier installed over the sub-slab insulation before the slab is poured.

Right – Workers pour the concrete for the basement floor slab over a vapor barrier installed over rigid foam.

Right-Polyethylene sheeting is correctly installed over aggregate and taped to pillars and foundation wall

Rigid foam extends under the full slab and lines the inside edges of the foundation walls.

Rigid foam insulation and a thin slab were installed over the dirt and gravel of this sealed crawlspace

Rigid insulation and water control layers are installed on the exterior of a flat foundation wall; spray foam insulates the rim joist

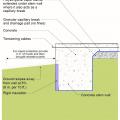

Spray foam extends down the foundation wall to the slab, which has been retrofitted by adding dimple plastic drainage mat and rigid foam insulation.

Spray foam extends down the inside of the foundation wall to the uninsulated slab; because the wall lacked exterior perimeter drainage, the slab was cut and an interior footing drain was installed.

Spray foam insulation extends down the foundation wall to the slab, which has been retrofitted by cutting the slab to install drainage mat against the wall and a new perimeter footing drain, along with rigid foam plastic above the slab.