Showing results 1 - 50 of 59

A coated OSB product with taped seams covers the walls to serve as both sheathing and weather-resistant barrier.

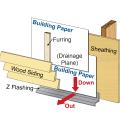

A drainage plane is created behind lap siding by installing furring strips on the exterior walls over house wrap which is overlapped and taped at all seams to serve as an air and water barrier.

A mesh plastic rainscreen product separates the coated OSB from the siding, providing a drainage space and ventilation gap.

A piece of siding is used as sill extension and to provide slope in the opening for the window, which is deeper because exterior rigid foam has been added

A plastic mesh rain screen is installed over the rigid foam to provide an air gap behind the exterior cladding allowing for drainage and drying.

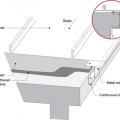

A strip of OSB sheathing is installed along the perimeter when retrofitting a flat roof with a parapet

A water-resistant membrane that takes the place of house wrap is sprayed is painted over seams and window framing then sprayed over the entire wall to provide a weather-resistant air barrier.

Closed-cell foam is sprayed into roof cavities along the masonry parapet wall to form a continuous air barrier between the wall and the sheathing of the flat roof

Closed-cell spray foam fills the roof joist cavities forming an air barrier between the masonry parapet wall and the roof sheathing

Extruded polystyrene (XPS) rigid foam is taped at the seams to provides a continuous air and weather-resistant barrier so no house wrap is needed; it also provides a continuous layer of insulation.

Furring strips are installed over a foil-faced rigid foam sheathing to provide a drainage plane and ventilation gap behind siding.

Furring strips provide a ventilation gap between the coated OSB sheathing and the fiber cement siding.

High winds pulled the asphalt shingles and sheathing panels off this coastal home, although storm shutters protected the windows

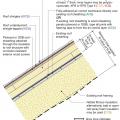

New coated OSB roof sheathing is installed over the existing sheathing of the flat roof and taped at the seams to provide a continuous air barrier

Over the coated sheathing air barrier, the builder installed a continuous layer of 2-inch rigid foam and then covered this with a yellow mesh rain screen layer.

Over the taped rigid foam board, 2x4 furring strips provide a ventilating air gap and drainage plane under the engineered wood lap siding. The furring strips were attached with structural screws to provide an attachment surface for the siding.

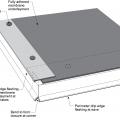

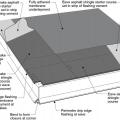

Polyisocyanurate rigid foam insulation is installed in multiple layers with staggered, taped seams over the flat roof

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Retrofit an existing roof by installing rigid foam, new moisture and air control layers, new sheathing, and new cladding plus cavity insulation in the roof rafters to create an unvented attic

Right - Here, air control is established by taping the seams of the plywood panel sheathing. The roof sheathing is also trimmed flush with the wall sheathing to allow a simple and airtight connection between the roof and wall assemblies

Right - Open-web floor and ceiling trusses provide space for ducts in conditioned space.

Right - The air control membrane installed over the roof sheathing is continuous. It connects to the air control of the wall around the entire perimeter without interruption. The roof overhangs have been cut off to make this connection continuous

Right - These roof insulation panels are installed in multiple layers with joints offset both vertically and horizontally. The plywood nail base fastened to the roof framing holds the insulation layers together snuggly thus minimizing gaps

Right – A rigid corrugated rain screen product is installed shingle-fashion with overlapping edges behind rock veneer.

Right – A rigid rain screen product completely covers the wall behind the cladding and window framing.

Right – Furring strips provide a drainage and ventilation gap between the siding and the cork insulation.

Right – Furring strips were installed to provide a 3/8-inch drainage plane over the rigid foam and under the fiber cement lap siding.

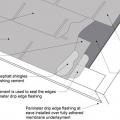

Right – If drip edge flashing is installed over fully adhered roof membrane at eaves, use flashing cement to seal the upper edge of the flashing

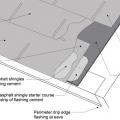

Right – Install asphalt shingles over a starter strip set in an 8-inch strip of flashing cement

Right – Ripped OSB provides furring strips for a ventilation gap behind the wood siding.

Right – Start asphalt shingle installation with a starter strip set in an 8-inch strip of flashing cement

Right – Taping the roof sheathing seams can greatly decrease the likelihood of water infiltration into a home in the event of a hurricane.

Right – The coated OSB sheathing can take the place of house wrap to serve as the weather-resistant barrier because it is sealed at the seams with a paint-on flashing.

Right – Under metal roofing, sheathing is protected by metal edging over a fully adhered membrane and a slip sheet of loose laid building paper

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

Rigid mineral wool insulation is covered with ¼-inch wood battens which provides a air and drainage gap under the cedar and fiber cement siding.

Sheathing is removed from a flat roof to retrofit with air sealing, insulation, and water control layers

Sleepers (tapered wood furring strips) are installed over the existing board sheathing to slope the new sheathing toward the drain in this flat roof retrofit

The builder installed a rain screen product that provides an air gap and drainage plane between the coated OSB sheathing and the cladding; the fabric layer folded over the bottom edge forms an insect screen.

The existing sheathing boards are removed near the perimeter of the flat roof and pressure-treated plywood is installed at the vertical face of the parapet

The exterior of the home is wrapped in a continuous layer of rigid foam with all seams taped to provide a thermal, air, and moisture barrier and serve as a drainage plane, eliminating the need for house wrap.

The metal screening keeps insects out of the black mesh plastic fabric which provides a ventilation gap behind the home’s siding, which includes the ship-lapped cypress shown here.

The retrofitted flat roof has PV panels and walking mats installed over the roofing membrane

The walls of this mixed-humid location home are constructed with moisture-resistant steel-framed expanded polystyrene R-34 wall panels that are designed to withstand winds up to 200 mph and level D seismic forces.