Showing results 1 - 97 of 97

A masonry chimney is reconstructed to withstand seismic forces by adding an insert to the existing firebox

A masonry chimney is reconstructed to withstand seismic forces by completely retrofitting the firebox and chimney using light-frame construction on the top of the foundation

A masonry chimney is reconstructed to withstand seismic forces by maintaining the current firebox but replacing the chimney section with a metal flue and light-weight chimney enclosure.

A masonry chimney is shortened and capped at roof level to reduce its chances of detaching in high winds or earthquakes; the fireplace can no longer be used.

A thermosiphon solar hot water system heats a fluid in the solar collector; the heated fluid heats potable water in a roof top tank.

Add metal connectors to strengthen framing connections in an existing wall from inside the home by removing drywall.

Buildings damaged by a hurricane storm surge: upper homes on gulf shoreline were hit by large waves above the lowest floor, lower left home on bay and right school 1.3 miles from gulf shoreline were hit by surge and small waves.

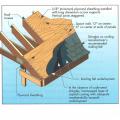

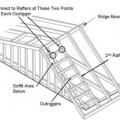

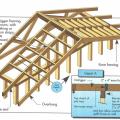

Ceiling joists extend out to provide very strong roof overhangs that will resist uplift pressures in high winds.

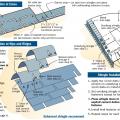

Composition shingle roofing system showing sheathing and hot-mopped underlayment

During high wind events, high localized areas of negative pressure (“suction”) occur above roof membranes

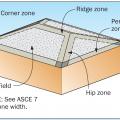

During high wind events, vortices form along the edges of the roof creating areas of localized negative pressure (“suction”) above the roof

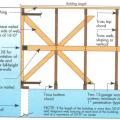

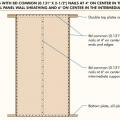

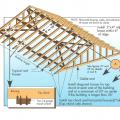

Example A of a gable truss and gable end wall bracing for a home in a hurricane region

Example B of a gable truss and gable end wall bracing for a home in a hurricane region

Failure of "S" tile roofing in high winds due to bond failure between mortar and tiles.

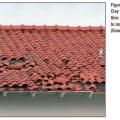

Failure of barrel tile roofing due to bond failure between underlayment, mortar, and tiles during a hurricane.

Failure of extruded concrete flat tile roofing due to bond failure between tile, mortar, and underlayment resulting from hurricane force winds.

Failure of Roof Structure from Pressurization Due to Window Failure During a Hurricane.

Gable end vents allow in wind-driven rain because pressures that develop between the outside surface of the wall and the inside of the attic are sufficient to drive water uphill several inches.

In high wind zones, if roof tiles are fastened with screws or nails, consider using clips on tiles at the corners, ridges, hips, and perimeters.

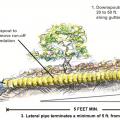

Kickout diverter flashing keeps bulk water from the roof from overflowing the gutter and continuously wetting the siding material.

Loss of the fascia cover in high winds exposes the vinyl soffit to entry by wind-driven rain.

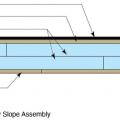

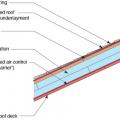

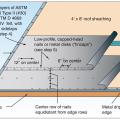

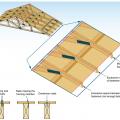

Low-slope roof assemblies constructed of two deck sheathing layers sandwiching rigid foam, and topped with mechanically fastened membrane

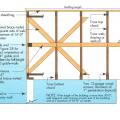

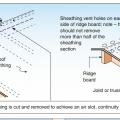

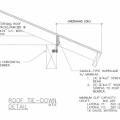

Nailing and ridge ventilation for roof sheathing used as a structural diaphragm in high-wind and seismic hazard areas.

Poor installation can result in the loss of tile roofing in high wind regions, regardless of whether the tiles are attached with mortar, screws, nails, or foam adhesive.

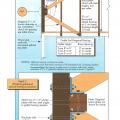

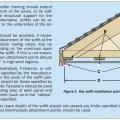

Provide structural supports that soffit panels can be nailed to at no less than 12 inches apart.

Recommended tile and mortar placement for extruded concrete flat tile roofing system

Right - A continuous load path connects the roof and wall framing to the foundation.

Right - An unvented attic with no soffit vents, borate-treated fascia board, metal drip edge, and concrete block construction on this south Florida home help make it resistant to hurricanes, pests, and wind-born wildfire embers.

Right - In hot climates, paint flat roofs light colors to reflect solar heat gain.

Right - Metal drip edge on this south Florida CMU home protects the top of the fascia and edge of the roof deck from water, wind-blown rain and embers, and insects.

Right - This concrete roof is properly attached and reinforced to withstand hurricane winds.

Right - This roof has a low gable and is secured to the wall framing to resist wind uplift.

Right – Closed-cell polyurethane foam is sprayed on the underside of the roof deck to provide structural connections and seal seams in the sheathing to increase wind resistance

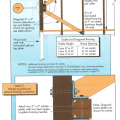

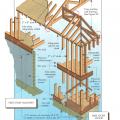

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

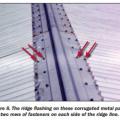

Right – The ridge flashing is secured with two rows of fasteners on each side of the ridge line

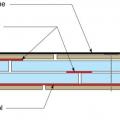

Right – The roof membrane is fully adhered and deck seams are sealed so the membrane will not flutter and fail due to negative pressure from high winds

Right – This hot-humid climate home employs several hurricane- and termite-resistant features including concrete block construction, borate-treated framing, a hip roof design with metal drip edge, impact-rated windows, and an unvented attic.

Right – This low-slope roof and parapet assembly has continuity of both the air and water barriers

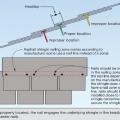

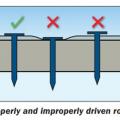

Roofing nails should be driven in straight and flush, not overdriven, underdriven, or angled

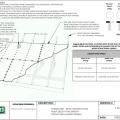

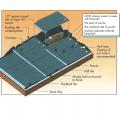

Seal the roof deck as follows: Sweep roof decking, tape seams, and cover underlayment or roofing felt as shown.

Soffits can be secured by caulking to the wall, sealing between each soffit panel and the wall channel, and screwing the wall channel to the soffit panels.

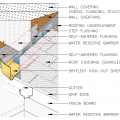

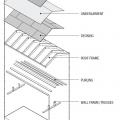

The components of a roof include the rafter framing or trusses, purlins, plywood roof decking, underlayment, and the roof covering.

This home was designed with continuous roof vents and few roof penetrations, allowing more room for the solar shingles that integrate with the asphalt shingles installed to meet IBHS Fortified Roof criteria for increased resistance to high winds and rain

This roof was constructed to meet the IBHS Fortified Roof standard by sealing the decking seams with flashing tape, installing synthetic roof underlayment secured with metal drip edge and nailed every six inches, and using self-adhered starter shingles.

Vinyl and aluminum soffit panels can blow away in high winds if not properly connected.

When installing fasteners in roof sheathing, common mistakes include using the wrong size fasteners, missing the framing members, overdriving nails, and using too many or too few fasteners.

Wrong - Roof deck sheathing nails missed the trusses, potentially weakening the roof in high winds.

Wrong - This concrete roof was not adequately attached and reinforced and failed in high winds.

Wrong - This roof failed in high winds due to lack of metal attachments to the framing.

Wrong – If roof membrane is not fully adhered, it can flutter and fail due to negative pressure from wind above and positive pressure from air leakage through roof deck below

Wrong – Roof underlayment is not fully adhered and roof deck seams are not sealed so roof is susceptible to high-wind events

Wrong – The clips holding these metal roofing panels were set too far from the roof eave (above red line) and the panels lifted in strong winds

Wrong – The metal panels covering this roof used snaplocks and concealed fasteners that gave way in high winds.

Wrong – The off-ridge roof vent on the right was poorly anchored and pulled off in high winds allowing water into the home.

Wrong – The ridge flashing fasteners were placed too far apart and came loose in high winds.

Wrong – The ridge flashing fasteners were placed too far apart and did not adequately hold the flashing in place

Wrong – These clay roof tiles were dislodged by high winds due to inadequate anchorage.

Wrong – This roof has no sheathing, when the metal panels blew off there was no secondary protection

Wrong – This roof membrane on a low slope roof is fluttering and may fail because it is not fully adhered and deck seams below are not sealed, allowing air to leak up into the assembly while the membrane is pulled up due to negative pressures from wind