Showing results 101 - 150 of 253

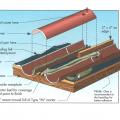

Recommended tile and mortar placement for extruded concrete flat tile roofing system

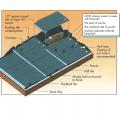

Right - A continuous load path connects the roof and wall framing to the foundation.

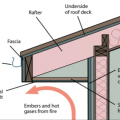

Right - An unvented attic with no soffit vents, borate-treated fascia board, metal drip edge, and concrete block construction on this south Florida home help make it resistant to hurricanes, pests, and wind-born wildfire embers.

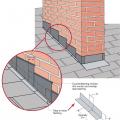

Right - Counterflashing tops a layer of step flashing which comes down above the asphalt shingle and a layer of L-shaped base flashing which comes down and extends below the shingle; the base flashing is adhered to the roof underlayment with mastic, shown

Right - In hot climates, paint flat roofs light colors to reflect solar heat gain.

Right - Leaf guards allow rainwater into the gutter but keep combustible debris out, increasing the home's resistance to wildfires.

Right - Metal drip edge on this south Florida CMU home protects the top of the fascia and edge of the roof deck from water, wind-blown rain and embers, and insects.

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right - Pieces of metal flashing are installed under each tile course along the valley centerline to prevent debris accumulation between and below concrete roof tiles.

Right - Spray foam insulation has been sprayed onto the underside of the sloped roof and the gable end wall to provide a sealed, insulated attic for housing the HVAC ducts

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right - The wall framing is connected to roof framing with metal ties for hurricane-resistant construction.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

Right - This concrete roof is properly attached and reinforced to withstand hurricane winds.

Right - This roof has a low gable and is secured to the wall framing to resist wind uplift.

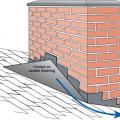

Right – A chimney cricket is installed and flashed to direct rainwater around the chimney

Right – All penetrations through the roof decking are sealed with paint-on flashing.

Right – Closed-cell polyurethane foam is sprayed on the underside of the roof deck to provide structural connections and seal seams in the sheathing to increase wind resistance

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

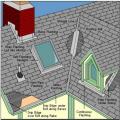

Right – Flashing is installed around chimney, skylight, vents, dormers, in valleys and at eaves

Right – House without gutters has waterproof liner, drain tile, and gravel bed extending more than 5 feet from foundation

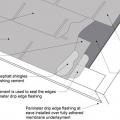

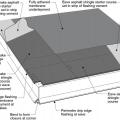

Right – If drip edge flashing is installed over fully adhered roof membrane at eaves, use flashing cement to seal the upper edge of the flashing

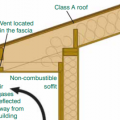

Right – In wildfire prone areas, using a flat soffit with venting on the fascia instead of an angled soffit with down-facing venting reduces the risk of catching rising embers.

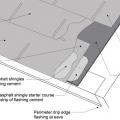

Right – Install asphalt shingles over a starter strip set in an 8-inch strip of flashing cement

Right – Rain barrel installed with an overflow spout terminating at least 5 feet from foundation

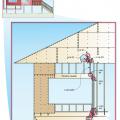

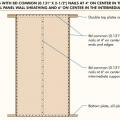

Right – Retrofit Specification for installing roof sheathing an 18-inch gable end overhang

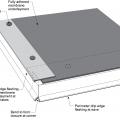

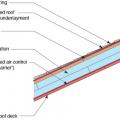

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

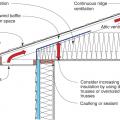

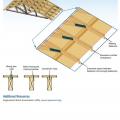

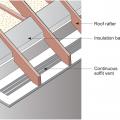

Right – Sheathing extends to rafters adding strength to soffit, baffles keep attic insulation from vent to maintain air flow

Right – Start asphalt shingle installation with a starter strip set in an 8-inch strip of flashing cement