Showing results 101 - 150 of 198

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

Right – Rigid air barrier installed between double-wall assembly. Inside cavity will be insulated

Right – This home is framed with double walls – two 2x4 walls set next to each other then sheathed with OSB on the exterior and netted on the interior face to create an extra-deep wall cavity that can be filled with blown-in insulation.

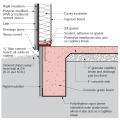

Right- This house uses CMU construction for flood and termite resistance as well as thermal mass

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

Single framed wall converted to double wall and insulated with closed-cell spray foam

Solid wood blocking was installed in the walls to accommodate future grab bars in both bathrooms.

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

Structural insulated panels offer a continuous layer of thermal protection and draft resistance around the home and come from the factory precut for fast assembly.

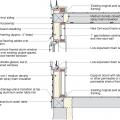

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The 2x4 wall studs are staggered along the 2x6 sill plate providing space to weave insulation around each stud to stop thermal bridging through the wall.

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The builder staggers 2x4 studs on 2x6 top and bottom plates which provides gaps to fill in insulation around the framing for a continuous blanket of insulation.

The components of a framed wall include from inside to out: gypsum, wood studs, OSB or plywood sheathing, and siding.

The double walls form a 12-inch cavity that was sheathed with a coated OSB then coated with 3 inches of closed-cell spray foam; they will be filled with 9 inches of blown fiberglass.

The energy-saving double wall construction uses two side-by-side stud walls, providing an extra-thick wall cavity that can be filled with more than twice as much insulation as a 2x6 wall.

The exterior walls are double walls consisting of two 2x4 stud walls set 3 inches apart to form a 10-inch-thick wall cavity that is filled with blown-in fiberglass to provide a continuous R-40 blanket of insulation around the home.

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The rim joists and top plates are air sealed and insulated with open-cell spray foam while the walls are filled with blown fiberglass.

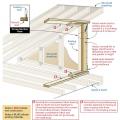

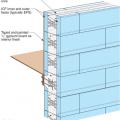

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

These factory-built walls consist of 9.5-inch I-studs sheathed with coated OSB, faced with OSB, and dense-packed with cellulose; a second interior surface of drywall is added to provide a 1.5-inch cavity for electrical wiring.

This 2x6 wall is advanced framed and filled with dense-packed cellulose insulation.

This home’s double-wall construction provides a 9-inch wall cavity for insulation.

This hot climate zone home uses high quality batt insulation between studs to insulate this connecting garage wall.

This hot climate zone home uses high quality batt insulation to insulate truss-joist headers.

This house is being built with advanced framing techniques including 2x6 24-inch on-center wall framing

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic