Showing results 51 - 100 of 101

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

Right – This home is framed with double walls – two 2x4 walls set next to each other then sheathed with OSB on the exterior and netted on the interior face to create an extra-deep wall cavity that can be filled with blown-in insulation.

Right – This hot-humid climate home is constructed with concrete block that is insulated on the inside with rigid foam; the framing is borate-treated lumber; the roof design is a high-wind-resistant hip roof with only one small gable over the entry.

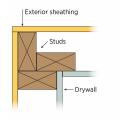

Right – This three studs in this corner are positioned to allow insulation against more of the exterior wall than standard three-stud corners.

Right- This concrete block home in the hot-humid climate is insulated on the interior with rigid EPS foam; all framing uses mold- and termite-resistant borate-treated lumber.

Single framed wall converted to double wall and insulated with closed-cell spray foam

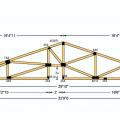

Specially designed roof trusses come with a two-foot by two-foot notch cut next to the center post providing space to install an insulated duct chase inside the home’s conditioned space but above the normal ceiling height.

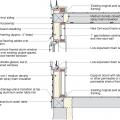

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The attic is sealed and insulated along the underside of the roof deck with 5.5 inches of polyurethane spray foam, providing conditioned space for the HVAC system.

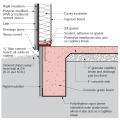

The basement walls’ interior framing is set in 3 inches from the concrete to allow space for closed-cell foam that is sprayed directly on the concrete, then blown cellulose is added to fill the wall cavity.

The double walls form a 12-inch cavity that was sheathed with a coated OSB then coated with 3 inches of closed-cell spray foam; they will be filled with 9 inches of blown fiberglass.

The energy-saving double wall construction uses two side-by-side stud walls, providing an extra-thick wall cavity that can be filled with more than twice as much insulation as a 2x6 wall.

The exterior walls of this home consist of two wall cavities: a 2x6 wall with plywood sheathing plus 8-inch I-joists sheathed with engineered wood; both cavities are dense-packed with cellulose for R-60 total.

The improved three-stud corner allows insulation to be installed later, in sequence

The main trunk line of the ducts runs within an insulated duct chase installed in a notch designed into the roof trusses that runs the length of the home to provide supply air directly to most of the home’s ceiling registers.

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The rim joists and top plates are air sealed and insulated with open-cell spray foam while the walls are filled with blown fiberglass.

These factory-built walls consist of 9.5-inch I-studs sheathed with coated OSB, faced with OSB, and dense-packed with cellulose; a second interior surface of drywall is added to provide a 1.5-inch cavity for electrical wiring.

This 2x6 wall is advanced framed and filled with dense-packed cellulose insulation.

This Habitat for Humanity builder ordered roof trusses with a 2-foot by 2-foot notch next to the center post then lined the cutout with rigid foam to form an insulated central duct chase to bring the heating and cooling ducts within the conditioned space.

This home’s double-wall structure consists of two 2x4 walls set two inches apart, then sheathed on the exterior and netted on the interior to create a 9.5-inch wall cavity that is filled with blown fiberglass insulation.

This hot climate zone home uses high quality batt insulation between studs to insulate this connecting garage wall.

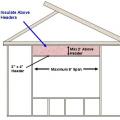

This hot climate zone home uses high quality batt insulation to insulate truss-joist headers.

This Kalamazoo Habitat for Humanity affiliate installs one layer of foam exterior of the studs and a second layer in between the staggered studs which are set only 2 inches apart to simplify the installation of additional fiberglass batt insulation.

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

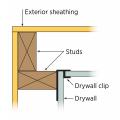

Two-stud corner using drywall clips; detail shows nail placement for exterior trim

Two-stud corners with drywall clips use the least wood and give the best thermal performance

When condensation forms on the interior side of wall sheathing and is not able to dry out, it can lead to mold growth and rotting of wall sheathing and framing

Windows are installed in new framing in preparation for adding exterior spray foam insulation

Wrong - Insulation beneath window is compressed and there are more support studs than necessary to left of window.

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen