Showing results 1 - 50 of 101

Example of the advanced framing technique, double-stud wall cavity, which will later be filled with blown insulation

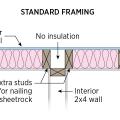

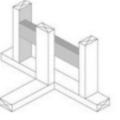

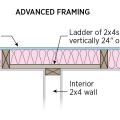

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

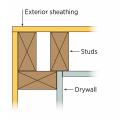

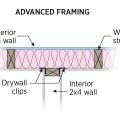

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

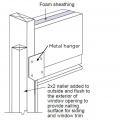

Advanced framing details include open headers and reduced framing around windows and two-stud corners to allow more room for insulation in the wall cavities while reducing lumber costs.

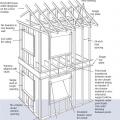

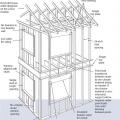

Advanced framing techniques including 2x6 walls spaced at 24 inches on center and ladder blocking at wall intersections allow more space for insulation in the wall cavities while open-web floor joists provide space between floors for ducting.

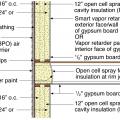

After spraying the 2x6 wall cavities with 2 inches (R-13) of closed-cell spray foam, the walls are covered with netting and an additional 3.5 inches of fiberglass (R-13) is blown in.

Attach the interior 2x4 wall to the exterior wall top plate with a flat metal connector plate

Baffles will keep insulation out of the soffit vents and wind out of the insulation in this vented attic.

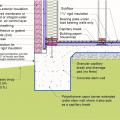

Brick veneer framed wall supported by a concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

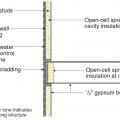

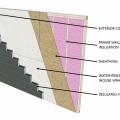

Closed-cell spray foam insulation is added to the wall cavities of an existing exterior wall

Construct a double wall consisting of two framed walls forming a wide wall cavity for more insulation in the home’s exterior walls.

Conventional three-stud corners leave a cavity that must be insulated by the framers—not good

Drywall was removed and the existing 2x4 walls were filled with 3.5 inches of dense-packed cellulose. Outside, the ½-inch plywood was topped with house wrap, 1.5 inches closed-cell rigid foam, 1x3 furring strips, and fiber cement siding.

Framing is built around the window before exterior rigid foam is installed on the exterior walls around the window.

ICF bricks are stacked to form hollow walls that are reinforced with steel rebar before the concrete is poured in

Installing ladder blocking at interior-exterior wall intersections rather than three solid studs in the exterior wall as the supporting surface allows room for insulation in the exterior wall.

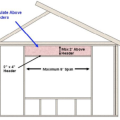

Instead of solid timber headers over windows, insulated headers can be used consisting of prefabricated structural insulated panels or site-fabricated with two sheets of plywood sandwiching a layer of rigid foam.

Instead of solid timber headers over windows, the headers can be insulated by using a sheet of plywood or one piece of solid timer on the exterior with a layer of insulation to the inside.

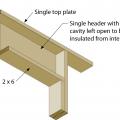

Insulated header made of one piece of plywood aligned with exterior wall, with room for insulation to inside

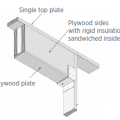

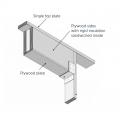

Insulated header made of two pieces of plywood that sandwich a layer of rigid foam insulation

Insulated headers can be hung with metal hangers instead of jack studs to reduce lumber usage

Insulating sheathing is extended up to the roof rafters and sealed around the framing with spray foam as part of this exterior wall retrofit

Interior wall attached with top plate metal connector, drywall clips support drywall, plan view

Interior wall attached with top plate metal connector, drywall clips support drywall, side view

Ladder blocking where exterior walls intersect interior walls provides more space for insulation and reduces thermal bridging.

Ladder blocking where interior and exterior walls intersect uses less wood and provides more room for insulation than stacking studs in the exterior wall to nail the interior wall to.

Ledger board, metal brackets, and vertical 2x4s have been installed in preparation for exterior spray foam in this retrofit exterior wall insulation technique

On top of the ice-and-water shield, the builder installed horizontal beams that were raised 6 inches off the deck to allow room for spray foam insulation.

Raised ceiling duct chase installation technique

Right - Closed-cell spray foam insulation fills the wall cavities of the exterior walls in this home retrofit

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - Raised-heel roof trusses allow more room at the eaves for attic insulation.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection