Showing results 151 - 200 of 248

In cold climates, install slab edge insulation when pouring slab on grade foundations.

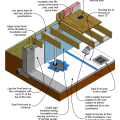

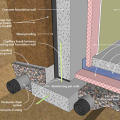

Pest proofing of this unvented crawlspace includes a metal termite shield that extends out from the sill plate, metal flashing wrapping the bottom of exterior rigid foam, and a termite inspection gap above interior rigid foam.

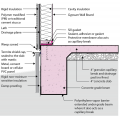

Right - A corrugated metal closure conceals the exterior rigid insulation at the slab edge

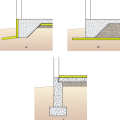

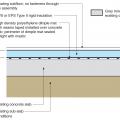

Right - Additional potential locations for slab-on-grade insulation include (a) under the slab and outside the perimeter with optional underground moisture block, (b) under the whole foundation, or (c) on top of the slab.

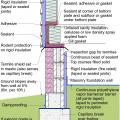

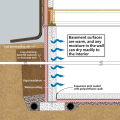

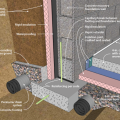

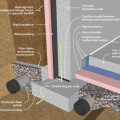

Right - Basement slab with a capillary break of either gravel or a drainage mat.

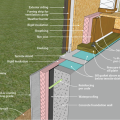

Right - Basement with exterior XPS or EPS insulation and insulation under the basement slab.

Right - Closed-cell spray foam covers the interior of the foundation wall and wall framing is placed to the inside of the spray foam.

Right - Closed-cell spray foam is used to retrofit an existing rubble basement foundation wall.

Right - Closed-cell spray foam was applied to the interior of a foundation wall.

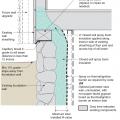

Right - Concrete masonry unit (CMU) basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Foil-faced polyisocyanurate insulating rigid foam sheathing is installed below the floor framing of this house built on piers; however, the seams should be sealed with metal taped and the plumbing elevated and protected.

Right - Foil-faced polyisocyanurate rigid foam board is tightly installed and sealed against a concrete foundation wall prior to installing fibrous blanket insulation.

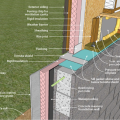

Right - Potential locations for basement insulation in new construction, slab insulation should always be underneath, with walls insulated (a) inside, (b) outside, (c) sandwiched inside, or (d) inside and outside of walls.

Right - Potential locations for crawlspace insulation: vapor sheeting should always cover the floor with insulation (a) outside walls, (b) inside walls, (c) both sides of walls, (d) sandwiched inside walls, or (e) under the first floor.

Right - Potential locations for slab-on-grade stem insulation in new construction: slab insulation should always be underneath, with stem walls insulated (a) inside, (b) outside, (c) not at all, or (d) outside with underground extension to repel moisture.

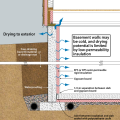

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the outside of the rigid foam.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Rigid foam insulation is installed along the exterior edge of an existing foundation slab.

Right - Rigid foam is installed over a waterproofing membrane that has been applied to the basement foundation walls.

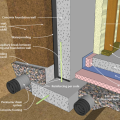

Right - The basement foundation is insulated on the exterior and termite shield extends out past the top of the insulation.

Right - The concrete basement wall is insulated on the interior with rigid foam; the footing detail is shown.

Right - The concrete masonry unit (CMU) basement wall has exterior insulation; the footing details include interior and exterior footing drain pipe.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The slab-on-grade foundation is insulated with two layers (R-20) of XPS foam under the-slab and R-10 on the exterior of the stem walls.

Right - This concrete basement wall is insulated on the interior basement walls with spray foam and under the slab with rigid foam; footing details are shown.

Right - This concrete basement wall is insulated on the interior with rigid insulation; sill details are shown.

Right - This concrete basement wall is insulated on the interior with spray foam insulation; sill detail are shown.

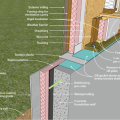

Right - This poured concrete basement wall is insulated on the exterior and under the slab with rigid insulation; footing details include interior and exterior footing drain pipe.

Right - This rigid insulation is correctly installed in a level layer over aggregate; the seams will be taped

Right - XPS rigid foam board is tightly installed against a concrete foundation wall and seams are sealed with tape prior to installing fibrous blanket insulation.

Right – 11-inch ICFs provide R-50 of wall insulation from the footing to the roof on this cold-climate home.

Right – After installing the insulated concrete foundation wall panels, the builder installed underslab rigid foam, which was topped by 4 inches of crushed rock then the poured slab.

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Prepoured foundation panels with integrated insulation and vapor barrier are installed in place.

Right – R-20 of XPS and polyiso rigid foam were added on the slab shelf that is part of this precast foundation wall system.

Right – Rigid foam was attached to the tops of the precast foundation walls to form an insulated edge for the floor slab.

Right – Spray foam insulation was sprayed onto the ground and along the sides of the foundation walls and piers of this insulated crawl space.

Right – The raised slab foundation has a 3-ft stem wall of filled concrete block, then is back-filled with compacted dirt and crushed rock, then insulated with 1” rigid foam covered with taped vapor barrier, under a floor slab.