Showing results 1 - 55 of 55

Apply self-adhesive flashing over top edge of the wall flashing, diverter, and housewrap

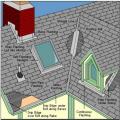

Chimneys and roof valleys are flashed with metal flashing that is integrated with roof shingles.

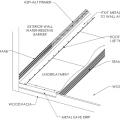

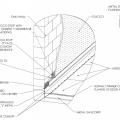

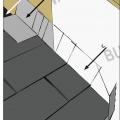

Continuous L-metal flashing integrated with underlayment at roof-wall intersections

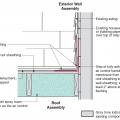

Existing wall-to-lower roof transition retrofitted with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding

Existing wall-to-lower roof transition with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding – view from eave

Existing wall-to-lower roof with attic transition with a new strip of fully adhered air control transition membrane, new step flashing, new roof underlayment, and new cladding – view from eave

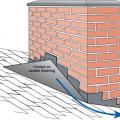

Improper flashing can allow rain water into walls, causing significant damage

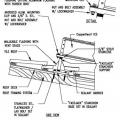

Install shingle starter strip then kick-out diverter; attach to roof deck but not sidewall

Integrate pre-formed vent pipe flashing, shingle-fashion, with roofing underlayment and shingles

Kickout diverter flashing keeps bulk water from the roof from overflowing the gutter and continuously wetting the siding material.

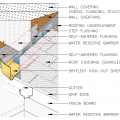

Metal cap flashing is installed over the roof parapet and extends down over the roofing membrane

Missing step flashing and kickout flashing caused rotting of wall and roof sheathing, fascia, framing, and plywood cover below the eave at this complicated roof juncture.

Place first shingle and next section of sidewall flashing over upper edge of diverter

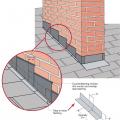

Right - Counterflashing tops a layer of step flashing which comes down above the asphalt shingle and a layer of L-shaped base flashing which comes down and extends below the shingle; the base flashing is adhered to the roof underlayment with mastic, shown

Right - Pieces of metal flashing are installed under each tile course along the valley centerline to prevent debris accumulation between and below concrete roof tiles.

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right – A chimney cricket is installed and flashed to direct rainwater around the chimney

Right – All penetrations through the roof decking are sealed with paint-on flashing.

Right – Flashing is installed around chimney, skylight, vents, dormers, in valleys and at eaves

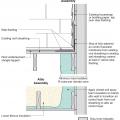

Right – The water-resistant barrier is layered over the step flashing to provide a complete drainage system

Spray foam adhesive provides an extra water resistant layer to the joints and seams on the inside of attics.

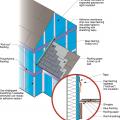

Step 1. Apply roof underlayment over roof deck and up the sidewall over the rigid foam insulation

Step 2. Install shingle starter strip then kick-out diverter as first piece of step flashing.

Step 3. Place the first shingle and the next section of sidewall flashing over upper edge of diverter

Step 4. Install remaining sidewall flashing, appropriate counter flashing, and shingles

Step 5. Apply self-adhesive flashing over top edge of the wall flashing, diverter, and rigid foam insulation

Step and kick-out flashing at all roof-wall intersections extending ≥ 4 in. on wall surface above roof deck and integrated with drainage plane above

Strips of roofing membrane are used to flash around a skylight on a flat roof retrofit

The blocking is completely flashed with roofing membrane before the PV rack hardware is attached on a flat roof

The retrofitted flat roof has PV panels and walking mats installed over the roofing membrane

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

Wrong - House wrap was not properly cut and adhered where the roof meets the wall so water is likely to get behind the house wrap.

Wrong - House wrap was poorly cut at wall interface and not taped leaving wood exposed and vulnerable to water entry.

Wrong - Roof is missing metal drip edge to cover the edge of OSB roof decking, roof underlayment should be trimmed back, and asphalt shingles are poorly installed.

Wrong - Roof-wall juncture lacks metal flashing and is poorly designed, thus encouraging water entry.

Wrong - Step flashing is missing where the gable meets roof and the valley flashing is incorrectly on top of rather than under shingles.

Wrong - The siding on the chimney is rotten because there is no metal step flashing at the base of the chimney.

Wrong - There is no step flashing along the base of the gable and the right window is missing sill trim.

Wrong – The flashing of the roof-wall juncture was installed above the roof shingles instead of below the roof shingles; also no kickout flashing was installed.

Wrong – the water-resistant barrier is layered underneath the step flashing, which could allow water to get behind the step flashing and into the wall.