Showing results 1 - 120 of 120

Individual ventilation systems for each dwelling unit in a multifamily building will require large numbers of penetrations in exterior facades

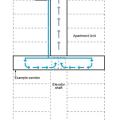

This central ventilation system uses an energy recovery ventilator to supply air to the corridor and exhaust air from the elevator shaft of a multifamily building

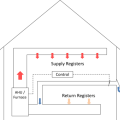

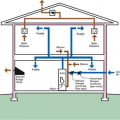

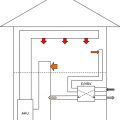

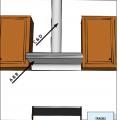

A central fan-integrated supply system uses a fresh air intake ducted to the home's central furnace or air handler unit to supply fresh air throughout the home

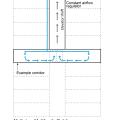

A central rooftop fan supplies outdoor air to all floors of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

A central rooftop fan supplies preconditioned outdoor air to every floor of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

A fresh air inlet is ducted to the return side of the home’s central air handler; a motorized damper and electronic controls help balance the flow of fresh incoming air with controlled exhaust to meet ventilation requirements

A passive air inlet is one approach to providing makeup air when operating an exhaust-only ventilation system

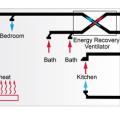

An energy recovery ventilator (ERV) transfers both heat and moisture between incoming and outgoing streams of air

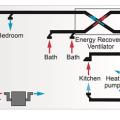

An Energy Recovery Ventilator provides outside air to this dwelling unit; a range hood with dedicated makeup air provides local kitchen exhaust; a Packaged Terminal Heat Pump provides conditioned air and dehumidification is provided separately

An Energy Recovery Ventilator provides outside air to this dwelling unit; a range hood with dedicated makeup air provides local kitchen exhaust; a Packaged Terminal Heat Pump provides conditioned air

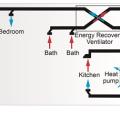

An Energy Recovery Ventilator provides outside air to this dwelling unit; a range hood with dedicated makeup air provides local kitchen exhaust; a radiant heating system provides heating

An in-line exhaust fan supplements the ability to exhaust moisture-laden air and lint from a dryer

At the outlet of the dryer exhaust duct, install a hooded vent with a louvered damper

Back-draft damper still has a piece of tape that prevented it from rattling during shipping

Bathroom exhaust fans are timer-operated to encourage removal of moisture from the home.

Clothes dryers vented directly to outdoors, except for ventless dryers equipped with a condensate drain

Continuously-operating ventilation & exhaust fans include readily accessible override controls

Dryer exhaust duct should vent directly to the exterior via a smooth, rigid metal duct

Dryer vent is run vertical with a 90 degree bend and does not vent to the outside

Each unit in a multifamily building should have its own supply and exhaust ventilation

Ensure that attached garages in multifamily buildings are well-ventilated to reduce the presence of airborne contaminants in the garage and occupied space

Fan CFM rating is higher than the requirement increasing the likelihood that it will meet the performance level once installed

Fan CFM rating is higher than the requirement increasing the likelihood that it will meet the performance level once installed

Fans from seperate dwellings exhausted together without back-draft dampers and not sealed

Fans supply outdoor air tempered by indoor corridor air to the corridors of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

For better temperature distribution and air quality, every bedroom and all of the common spaces in this home have ducted returns to the central heat pump and all bathroom exhaust fans are controlled by a condensation sensor and timer switch.

Fresh air intakes and exhaust vents are ducted to each unit in this multifamily building

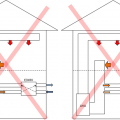

If integrating an ERV/HRV with the heating/cooling duct system, add dedicated ducts for either the supply or return side to prevent short-circuiting of air distribution

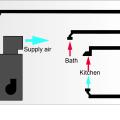

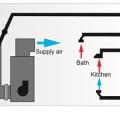

In this dwelling unit ventilation configuration, a forced air system provides outside air at the same rate as the air being exhausted from the bathroom fan; local kitchen exhaust is provided by a range hood with a dedicated makeup air intake

In this ventilation configuration for a multifamily building, outside air enters through a dedicated outdoor air system (DOAS), and inside air exits the space through bathroom and kitchen exhaust fans

In this ventilation configuration, an air handler provides outside air at the same rate as the air being exhausted from a bathroom fan; local kitchen exhaust has a dedicated makeup air intake; dehumidification is provided separately

Lower-cost local ERVs are usually installed in a ceiling to supply outdoor air to and exhaust air from the room in which they are located

Opening the outlet on a bath fan reveals model information and provides access to the motor

Operable windows can provide fresh air to a multifamily building but each unit should also have it’s own fresh air intakes and exhaust vents

Packing tape has been removed and damper will be able to function properly once fan is installed

Preconditioned outdoor air is supplied to the corridors on each floor of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

Right - Each individual unit in this multifamily building has its own energy recovery ventilator (ERV) to provide balanced ventilation to the dwelling

Right - The exhaust duct has been mechanically fastened and sealed with mastic.

Right - The exhaust vent duct terminates to the outdoors with a vent cover that has been properly caulked and covered with a metal pest screen.

Right - The kitchen exhaust duct termination is integrated aesthetically and functionally with the exterior cladding; however, the opening should be screened to keep out pests.

Right - This enclosed parking garage in a multistory multifamily building is equipped with mechanical exhaust to remove airborne contaminants from the garage.

Right - This kitchen exhaust duct termination is integrated aesthetically and functionally with the exterior cladding.

Right - This manufacturer's label shows a CFM higher than the requirement, increasing the likelihood that it will meet the performance level once installed.

Right - This shared enclosed parking garage is equipped with exhaust fans to remove airborne contaminants from the garage.

Right – The termination of this kitchen exhaust duct is sealed to the wall to keep out air and water and is screened to keep out pests.

Right – This bath fan runs continuously at low speed and is activated by a motion sensor to operate a higher speeds.

Right – This exhaust fan duct is made of smooth rigid metal and the duct is mastic sealed at the joints.

Right – This home’s kitchen exhaust fan motor is housed in a box above the ceiling.

Right – This kitchen exhaust duct is made of smooth rigid metal and the duct is mastic sealed at joints

Right – This kitchen exhaust fan duct is made of smooth round steel duct that takes the shortest, most direct route to the outdoors and joints are sealed with mastic.

Right – This kitchen exhaust fan has a damper to prevent outside air from entering when the fan is not operating

Right – To minimize sound in the kitchen, the exhaust fan above the island-mounted stove top is located above the ceiling rather than just above the stovetop.

Separate exhaust fans can share a common exhaust if each exhaust fan is equipped with a back-draft damper to prevent cross contamination

Seperate dwellings with their own seperate exhaust terminations

The back-draft damper on this exhaust fan is closed to prevent cross contamination

The back-draft damper on this exhaust fan is open when the exhaust fan is operating

The back-draft damper open when the fan is actively exhausting and closes when the fan is off

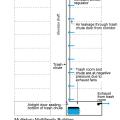

The elevator shaft in this multistory multifamily building has an exhaust fan that maintains a slight negative pressure to control odors; there is also a smoke vent that is dampered closed during normal conditions.

The ENERGY STAR logo on the manufacturer’s label indicates this is an ENERGY STAR qualifying exhaust fan

The individual exhaust systems for each dwelling unit in this multifamily building result in large numbers of penetrations in the exterior façade

The manufacturer’s label found on this exhaust fan housing shows a sone rating of 1.0

The trash chute and trash room in a multistory multifamily building are depressurized with exhaust fans to minimize odors.

These ERV/HRV configurations are NOT recommended because outdoor air can be sucked back into the ERV/HRV before being distributed to the living space

This air handling unit provides outside air at the same rate as the air being exhausted from the bathroom exhaust fan; local kitchen exhaust is provided by a range hood with a dedicated makeup air intake and dehumidification is provided by a separate unit

This central ventilation system uses an energy recovery ventilator, pre-conditioning unit, and elevator shaft exhaust fan to supply air to dwelling units and corridors and to exhaust air from units and the elevator shaft in a multifamily building

This ducted, wall-mounted range hood exhaust fan replaced a recirculating fan that did not adequately remove kitchen contaminants.

This energy recovery ventilator (ERV) provides balanced ventilation to a dwelling unit in a multifamily building

This HRV, installed in a conditioned attic, provides balanced ventilation to the whole home

Ventilation in this dwelling unit is provided by an Energy Recovery Ventilator; local kitchen exhaust is provided by a range hood with a dedicated makeup air intake; conditioned air is provided by an air handler

Ventilation in this unit is provided by an Energy Recovery Ventilator; local kitchen exhaust is provided by a range hood with a dedicated makeup air intake; conditioned air is provided by an air handler and dehumidification is provided separately

Without an exhaust fan ducted to the exterior, particles resulting from cooking can accumulate on walls and ceilings, and will be present in the air where they can damage occupants' respiratory systems

Wrong - Code requires a kitchen exhaust fan duct to be a smooth metal duct (galvanized steel, stainless steel, or copper) and to terminate outside, not in an attic or crawlspace.

Wrong - Exhaust fans should not have tight bends in duct work, especially right next to the fan as this can block airflow

Wrong - Flex ducts are prohibited by the IRC for kitchen exhaust and, at 28 feet, this duct is too long to be effective.

Wrong - If this kitchen exhaust duct had been extended a few inches, at least one bend could have been eliminated.

Wrong - Kitchen exhaust ducts are prohibited from terminating within 3 feet of an operable window or near gable vents.

Wrong - Kitchen exhaust fans must be located directly over the stove top to be effective at capturing and removing cooking pollutants.

Wrong - the CFM rating may not meet the performance specification once installed, and the sone rating is too high.

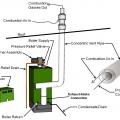

Wrong - The furnace intake and exhaust are too close to each other and are missing rodent screening.

Wrong - The furnace intake and exhaust are too close to each other and should be facing different directions.

Wrong - The IRC prohibits the use of flex duct for kitchen exhaust and only permits PVC duct for downdraft systems that meet specific exceptions; also, gaps at the ceiling have not been air sealed.

Wrong - The IRC requires that kitchen exhaust ducts terminate outside, at least 3 feet from operable windows.

Wrong - This kitchen exhaust duct uses flex duct, which is prohibited by code, and the duct’s 22-foot length and multiple bends will slow the movement of pollutants out of the home.

Wrong - Two exhaust terminations are joined in a roughly cut, restrictive hole that is not air sealed.

Wrong – Exhaust fan ducts must be smooth metal ducts; flex duct is not permitted by the IRC.

Wrong – Overly powerful kitchen exhaust fans can backdraft other combustion appliances in the home

Wrong – The duct for this kitchen exhaust fan is made of flex duct instead of smooth metal duct and the duct is not properly supported.

Wrong – The kitchen exhaust fan duct is attached to flex duct, which is prohibited by code.

Wrong – The position of this exhaust fan does not allow the duct to route directly outside in as straight a path as possible.

Wrong – These flex ducts are pulled taut, which is correct but they are inadequately supported with straps that are spaced too far apart and are too tight causing pinching of the insulation and turns are sharp rather than gradual.

Wrong – This exhaust duct extends far beyond what is needed to reach the roof; a short, straight, smooth rigid metal duct is best for exhaust ducts and exhausting to the soffit vent would be preferable.

Wrong – This exhaust fan duct is wrong on several counts: it uses flex duct rather than smooth round metal duct as required by the IRC, the duct terminates inside of the wall assembly instead of outside, the opening is not large enough...

Wrong – This kitchen exhaust is a recirculating model; kitchens should use exhaust fans that duct out through the roof to remove moisture and odors from the home