Showing results 1 - 100 of 221

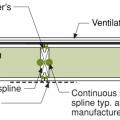

A structural spline made of a solid 2x is used where needed to meet structural load requirements at SIP panel seams

A surface spline reduces thermal bridging much more than a structural spline at SIP panel seams

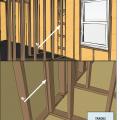

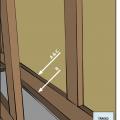

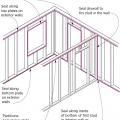

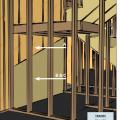

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

Advanced framing details include using the minimum amount of wall studs permitted by code.

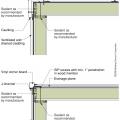

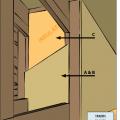

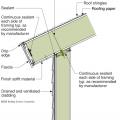

Air barrier is continuous across several components of the lower section of wall

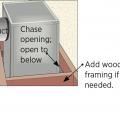

Air seal and insulate double-walls that are half-height or full-height walls used as architectural features in homes.

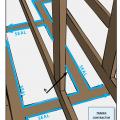

Air seal the common wall between units in a multifamily structure to minimize air leakage.

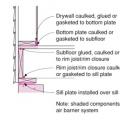

Air-seal above-grade sill plates adjacent to conditioned space to minimize air leakage.

Air-seal drywall to top plates at all attic/wall interfaces to minimize air leakage.

An all-terrain forklift is used to move and stage the panels

An insulated spline is another option for avoiding thermal bridging at SIP panel seams

Closed-cell spray foam insulation is added to the wall cavities of an existing exterior wall

Construct exterior walls with insulated concrete forms (ICFs) that provide insulation without thermal bridging, as well as air sealing, a drainage plane, and high structural strength.

Construct exterior walls with structural insulated panels (SIPs) to provide an airtight wall with consistent insulation and very little thermal bridging.

Draft stopping and air barrier at tub enclosure − plan view

Expanded polystyrene insulation is installed with joints taped and lath attached in preparation for the application of stucco

Exterior fiberglass insulation on this new home was (incorrectly) cut to terminate below-grade after backfill, which will expose the above-grade portions of the foundation wall to cold temperatures

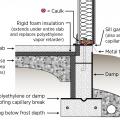

Exterior XPS basement insulation is correctly installed to completely cover the foundation wall

Floor cavity air pressure is measured by placing a tube into the floor cavity through a small drilled hole

Floor cavity pressure is measured by inserting a tube into the floor cavity using an extension pole

Foil-faced rigid foam and spray foam can be used to insulate a basement on the interior; use good moisture management techniques to keep the basement dry

Gaps at shared common walls can be a significant source of air leakage in multi-family buildings

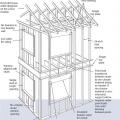

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

Identify what materials will constitute the continuous air barrier around the building envelope.

Infrared imaging shows cold conditioned air pouring out of the open floor cavities under this attic kneewall into the hot unconditioned attic

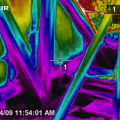

Infrared thermography during depressurization testing reveals air leakage at corner of spray foam-insulated room where wood-to-wood seams in framing were not air sealed

Install a foam gasket along top plates before installing drywall

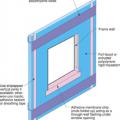

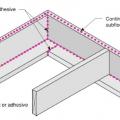

Install a housewrap drainage plane between the SIP panels and the exterior cladding

Install a rigid air barrier to separate the porch attic from the conditioned space.

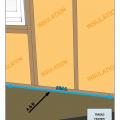

Install continuous rigid foam insulation or insulated siding to help reduce thermal bridging through wood- or metal-framed exterior walls.

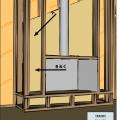

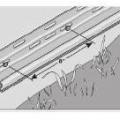

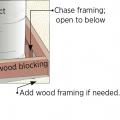

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

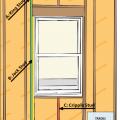

Lay out the rigid foam sheathing joints so they do not align with the window and door edges

Lifting plates attached to the wall provide good bracing to tighten up SIP panel seams

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

Make sure the beads of caulk are continuous the full length at each SIP panel seam, such as at the wall-roof seam, to maintain air barrier continuity

Peel-and-stick panel tape provides added assurance that SIP panel seams will remain airtight

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Right - A termite shield and a sill gasket are installed between the sill plate and the foundation on a raised slab foundation.

Right - Furring strips were installed with blocking to allow adequate room for 4 inches of mineral wool.

Right - Mineral Wool insulation is installed on the exterior of wall with furring strips.

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right – Air barrier and penetrations sealed between porch attic and conditioned space

Right – Air barrier installed under staircase (picture taken from house looking into attached garage)

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

Right – Appropriate use of framing members to support double windows and additional cripples for drywall purposes

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary