Scope

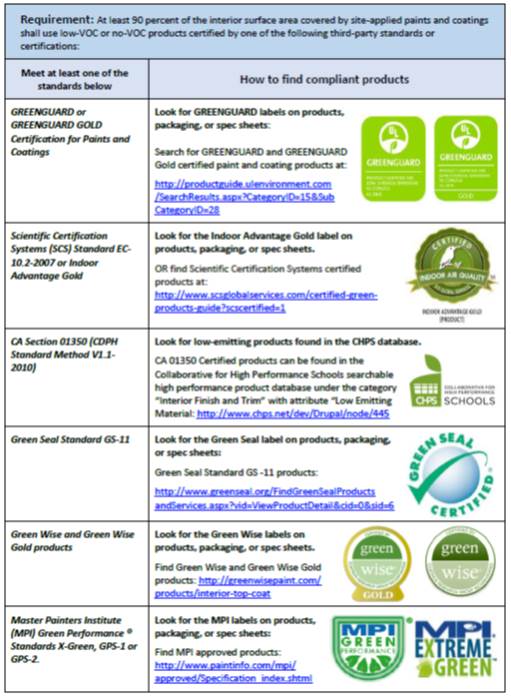

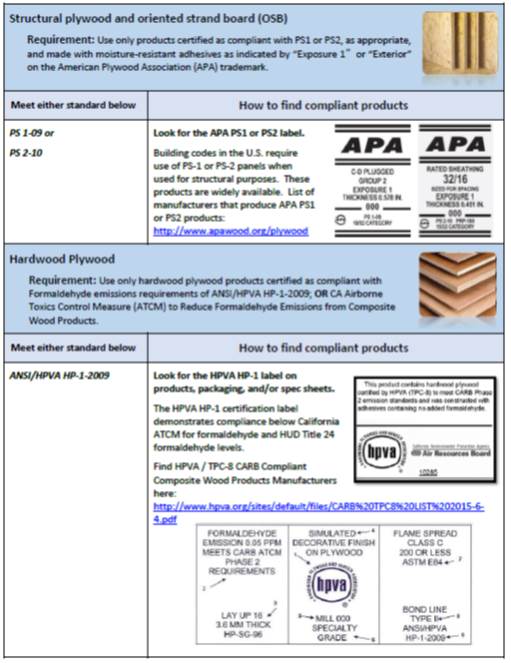

In all living spaces, utilize third-party certified low-emission composite wood materials that are designed to reduce human exposure indoors to individual VOCs. The How to Find Indoor airPLUS Compliant Low Emission Products document provides guidance on identifying compliant products including industry databases and examples of product labeling.

These specifications apply to:

- Structural Plywood and oriented strand board

- Hardwood plywood

- Particleboard and MDF products

- Cabinetry

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Formaldehyde is traditionally used as part of the adhesive, or “binding agent,” in composite wood products such as particleboard, plywood, medium density fiberboard (MDF), and oriented strand board (OSB). Elevated levels of formaldehyde, which becomes a gas at room temperature, can cause burning sensations in the eye, nose, and throat; nausea; difficulty breathing. It can also trigger attacks in people with asthma. High levels of exposure may cause some types of cancers.

The rate of release of formaldehyde from products such as pressed wood or textiles can vary. Emission levels of newer pressed wood products are generally higher than that of older products and can increase with high indoor temperatures or humidity.

On July 7, 2010, President Obama signed the Formaldehyde Standards for Composite Wood Products Act into law. This legislation, which adds a Title VI to the Toxic Substances Control Act (TSCA), establishes limits for formaldehyde emissions from composite wood products: hardwood plywood, medium density fiberboard, and particleboard. The national emission standards in the Act mirror standards previously established by the California Air Resources Board for products sold, offered for sale, supplied, used, or manufactured for sale in California. Learn more.

Using certified products lowers occupants’ risk of exposure to high levels of formaldehyde from construction materials. These Indoor airPLUS specifications can be implemented by requiring documentation of material certification for each material submittal package from sub-contractors. Any submittal requirements, such as manufacturer documentation of product certifications, should be clearly outlined in the project specifications and/or subcontractor bid package. Information for each third party certification and emissions standard required by Indoor airPLUS can be found in the report How to Find Indoor airPLUS Compliant Low-Emission Products.

The report provides guidance on identifying compliant products including industry databases and examples of product labeling. The guide also includes more detailed descriptions of the compliant third-party standards and certifications applicable to low-formaldehyde composite wood. Utilize this guide when outlining detailed product certifications to be included in the project specifications and/or subcontractor bid package.

Success

To ensure Indoor airPLUS Item 6.1 requirements are met, incorporate the requirements for product certification into the project’s specifications and/or bid package. Require documentation of product compliance for each product submittal from sub-contractors and suppliers.

Climate

No climate specific information applies.

Compliance

Compliance

Retrofit

SCOPE

Guidance for the measures described in this guide is applicable to both new and existing homes.

Follow safe work practices as described in the Global Worker Safety section of the Standard Work Specifications.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

U.S. Environmental Protection Agency, Indoor airPlus program and PNNL.

Sales

No Formaldehyde Pressed Wood =

Formaldehyde is traditionally used as an ingredient in the adhesive or “binding agent” of composite wood products such as particleboard, plywood, medium density fiberboard (MDF), and oriented strand board (OSB). Elevated levels of formaldehyde, which becomes a gas at room temperature, can cause burning sensations in the eye, nose, and throat; nausea; and difficulty breathing. It can trigger attacks in people with asthma and at high levels of exposure may cause some types of cancers. Certified low/no formaldehyde board products help provide a healthy indoor environment by minimizing these emissions.