Showing results 2901 - 3000 of 4973

Right – The entire first floor and second floor of these modular homes were assembled in the factory and installed on an insulated concrete basement foundation on site.

Right – The exhaust fan duct is sealed to the fan with mastic and the fan opening is covered with cardboard to keep out dust during construction.

Right – The existing home on this site was in poor condition and was demolished to make room for a new highly efficient DOE Zero Energy Ready home.

Right – The exterior unit of the mini-split heat pump is installed on blocks on a concrete pad to keep the equipment elevated above mud and water runoff.

Right – The exterior wall cavities are completely filled with dense-packed cellulose.

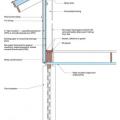

Right – The flashing is properly installed to create a complete drainage system with continuous rigid insulation sheathing/siding

Right – The floor and wall system on this open-foundation home use rigid foam rather than fibrous cavity insulation to reduce risk of water damage.

Right – The foundation of this ICF home was constructed of ICFs that were set in place on a gravel bed, then 3.5 inches (R-36) of closed-cell spray foam was sprayed directly onto the gravel, providing an effective air, vapor, and thermal barrier.

Right – The foundation wall consists of prefab concrete wall panels with integrated insulation.

Right – The framing around the window is thoroughly flashed with liquid flashing.

Right – The hard metal ducts are located in conditioned space between floor joists and all seams are sealed with approved metal tape.

Right – The heat pump water heater is equipped with a recirculating pump to push hot water to distant fixtures.

Right – The heavy roof underlayment was wrapped over the edges and down onto the walls, providing a continuous air barrier at this critical juncture; the second story will have narrow overhangs, matching the existing architecture style in the neighborhood

Right – The home’s energy management system is installed in a utility closet next to the tankless water heater.

Right – The HVAC compressor is installed on a raised platform with a protective railing installed.

Right – The HVAC compressor sits on a raised cantilever platform away from the base flood elevation.

Right – The HVAC outdoor unit is anchored on a bed of masonry bricks, 1 foot or more above the base flood elevation.

Right – The HVAC unit installed in the insulated attic uses a heat pump to provide heating and cooling while also providing dehumidification and fresh air ventilation.

Right – The insulated concrete forms that are below-grade have a damp-proof coating to prevent moisture seeping into the foundation

Right – The insulating enclosure over this non-IC rated recessed light fixture is centered and air sealed

Right – The insulation has been located to the exterior of the thermal mass in this wall section

Right – The joint between the foundation wall and the mud sill is thoroughly sealed with a liquid-applied sealant.

Right – The latticework between columns in this raised foundation will allow free flow of water in the event of a flood

Right – The master bathroom has a handicapped-accessible shower with curbless entry and an adjustable-height hand shower.

Right – The outside unit of the mini-split heat pump system is installed on a concrete pad and away from shrubs.

Right – The passive radon vent stack is properly labeled; this pipe brings radon and soil gases collected via a perforated pipe located under the floor slab up through an exterior wall for venting out through the roof.

Right – The PEX piping and sink drain of this bathroom sink are fitted with escutcheons that help to air seal around the pipes and prevent pest entry.

Right – The PV system inverters and battery take up minimal space in the garage.

Right – The raised slab foundation has a 3-ft stem wall of filled concrete block, then is back-filled with compacted dirt and crushed rock, then insulated with 1” rigid foam covered with taped vapor barrier, under a floor slab.

Right – The raised-slab, brick-and-block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, CMU block stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

Right – The raised-slab, poured-concrete stem wall, above-grade walls, and roof of this house use flood damage-resistant materials, integrated water, vapor, and air control layers, and construction methods which promote good drainage and rapid drying

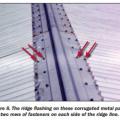

Right – The ridge flashing is secured with two rows of fasteners on each side of the ridge line

Right – The rigid insulation covers all exterior walls and all seams are taped to provide a complete drainage system

Right – The rim joists above the pre-insulated basement walls are sealed and insulated with spray foam to prevent air leakage at this juncture in the building envelope.

Right – The roof membrane is fully adhered and deck seams are sealed so the membrane will not flutter and fail due to negative pressure from high winds

Right – The rough opening around the window has been filled with low-expansion foam to air seal.

Right – The rough opening around window has been filled with backer-rod to air seal.

Right – The seam between the slab and the foundation wall is sealed with urethane caulk.

Right – The seams are taped on the coated OSB sheathing of this home to provide a complete air barrier.

Right – The sill plate was sprayed with foam prior to installation atop foundation.

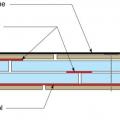

Right – The slab is coated with two coats of epoxy paint to minimize moisture transfer through the slab from the ground.

Right – The solar system production is tracked next to the home’s electrical meter.

Right – The spacer structure of these ICFs provides supports for attaching the fasteners used to attach the metal studs of the below-grade walls.

Right – The termination of this kitchen exhaust duct is sealed to the wall to keep out air and water and is screened to keep out pests.

Right – The top of the enclosure over this recessed can light remains clear of attic insulation

Right – The top plate-to-dry wall seams of the interior walls are sealed from the attic.

Right – The underside of this low-sloped roof is insulated with open-cell spray foam in this dry climate to achieve the code-required R-value; the builder used the same foam to insulate exterior walls.

Right – The walls of this home were constructed with “insulated studs” fashioned on site by adding 2-inch-thick strips of rigid foam to the inside face of 2x4 studs then topping that with a plywood nailing surface.

Right – The water-resistant barrier covers the entire house and the seams are taped to provide a complete drainage system

Right – The water-resistant barrier is layered over the step flashing to provide a complete drainage system

Right – The window header is filled with spray foam and sealant is used to air seal wood-to-wood seams; however, it would be preferable to design the wall to avoid so many stacked studs around the windows because they prevent wall insulation installation.

Right – There is a properly installed and layered self-sealing bituminous membrane at the roof penetration

Right – There is a self-sealing bituminous membrane installed at the valley of the roof prior to the roof felt

Right – There is flashing installed along the top of the window and the water-resistant barrier is layered over to create a complete drainage system

Right – There is flashing installed at the bottom of the wall to create a satisfactory drainage system

Right – thermal mass walls, small windows, and recessed porch and trees on the south side of this southwest home help to minimize solar heat gain.

Right – These modular homes are constructed in a factory and will be trucked to the site for installation on a permanent foundation.

Right – These modular homes are constructed in a factory that provides easy, ergonomic access to typically hard-to-reach areas of the home including under the floor.

Right – These three urban-infill cold-climate homes were built on insulated concrete foundations.

Right – This aluminum jalousie window provides solar control while allowing view and ventilation.

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right – This bath fan runs continuously at low speed and is activated by a motion sensor to operate a higher speeds.

Right – This builder installs 1 inch of XPS rigid foam on the exterior of the 2x6 walls then covers the foam with ½-inch plywood sheathing, which serves as a nailing surface for siding and trim.

Right – This coated OSB sheathing product is available with an integrated insulation layer.

Right – This column foundation has no HVAC equipment, piping, electrical components, or structural walls below the elevated floor system

Right – this commercial building employs good techniques to resist solar heat gain: awnings and pergolas over windows, recessed windows and entryways, deep tinting on glass, and shade plants.

Right – This crawlspace window was completely sealed off on the inside and outside with air barrier and water-proof materials and the window well was filled in to an above-grade height to prevent bulk water from entering the crawlspace

Right – This energy recovery ventilator provides fresh air and exhausts stale air through a heat exchanger that recovers heat from the outgoing air in winter and reduces heat from incoming air in the summer to provide ventilation without wasting energy.

Right – This exhaust fan duct is made of smooth rigid metal and the duct is mastic sealed at the joints.

Right – This exhaust fan use metal ducting that goes directly to the soffit to minimize penetrations through the roof.

Right – This exterior door is installed to swing out and has storm protection shutters.

Right – This fire-rated wall assembly uses exterior gypsum board and an exterior siding of fiber-cement or metal to increase fire resistance.

Right – This floor system on a column foundation is insulated using closed-cell spray foam rather than fibrous insulation

Right – This foil-faced foam sheathing has taped seams and proper flashing details so it can serve as a drainage plane.

Right – This heat pump water heater is equipped with a recirculation pump to speed hot water to distant faucets.

Right – This home is framed with double walls – two 2x4 walls set next to each other then sheathed with OSB on the exterior and netted on the interior face to create an extra-deep wall cavity that can be filled with blown-in insulation.

Right – This home solar system includes batteries that provide power during peak evening hours.

Right – This home uses a light-colored exterior wall to reduce solar heat gain

Right – This home uses a small-diameter high-velocity duct system with a main duct (plenum) that is one-fourth the size of a conventional duct and branch ducts with a 2- or 2.5-inch inside diameter.