Showing results 2851 - 2900 of 4973

Right – Spray foam insulates the walls and ceilings separating the garage from the home.

Right – Spray foam insulation fills the header above the door and fills the rim joist between floors.

Right – Spray foam insulation is sprayed on the underside of the roof deck to provide a conditioned space in this low attic for the HVAC ducts.

Right – Spray foam insulation was sprayed onto the ground and along the sides of the foundation walls and piers of this insulated crawl space.

Right – Spray foam is used to carefully seal behind plumbing that was installed in an exterior wall.

Right – Spray foam was installed at the sheathing intersection as well as the sill plate to sub-floor connection.

Right – Staggered 2x4s are placed every 12 inches on 2x6 plates, providing a nailing surface on each side of the wall every 24 inches.

Right – Start asphalt shingle installation with a starter strip set in an 8-inch strip of flashing cement

Right – Strategically placed trees provide shade to the south-facing windows of this building.

Right – Structural insulated panels are quickly assembled on site for this SIP house.

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – Subfloors are installed in a clean, dry, well-lit factory setting for these modular, factory-built homes.

Right – Tape and spray foam are used to air seal around pipes that extend through exterior walls.

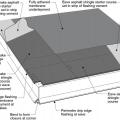

Right – Taping the roof sheathing seams can greatly decrease the likelihood of water infiltration into a home in the event of a hurricane.

Right – Terra cotta tiles are attached to horizontal metal furring strips as the exterior cladding over mineral wool insulation on this multi-family building in Colorado.

Right – the 2x6 walls are insulated with a flash-and-batt approach that includes spraying the wall cavities with one inch of open-cell foam to seal the sheathing to the framing then filling the wall cavities with R-19 fiberglass batts that are compressed

Right – The air- and water-barrier material lining the shower stall is mastic sealed to prevent leakage and rigid foam insulation is installed on the floor of the shower.

Right – The base of the wall is water proofed and the seam between the base of the wall and the sidewalk is air sealed.

Right – The basement contains four 5,000-gallon rainwater holding tanks for this home which meets all of its water needs with rainwater.

Right – The basement of this cold-climate home is insulated along interior walls with 2 inches of foil-faced rigid foam; finished basement walls also have a 2x4 interior wall insulated with R-19 blown-in fiberglass insulation and a poly vapor barrier.

Right – The blower door is installed snugly and securely to the door frame during testing

Right – The blower door pressure reference hose is placed well away from the outdoor side of the fan

Right – The builder constructed a mock up of the wall assembly for this multi-family building.

Right – The builder has provided homeowners manuals and racks to hold them on the side of the HVAC cabinet in the utility room.

Right – The builder provided adequate wall space for the solar inverter next to the home’s electric panels.

Right – The builder routed all vents through side walls to avoid holes in the roof.

Right – The building felt is installed on all exterior walls and provides a complete drainage system

Right – the building on the right employs light-colored walls, deep tinting, and deeply recessed windows to minimize solar heat gain

Right – The canopy of this tree is high enough to allow views out the windows of this home while providing excellent shade to walls, windows, and roof.

Right – The coated OSB sheathing can take the place of house wrap to serve as the weather-resistant barrier because it is sealed at the seams with a paint-on flashing.

Right – The corridor in this multistory building is pressurized with outdoor supply air.

Right – The double compressor unit supplies multiple interior minisplit heat pump heads.

Right – The double-pane windows have low-emissivity coatings on three surfaces to reduce heat transfer through the glass allowing in views but preventing heat loss in winter and heat gain in summer.

Right – The downspout pipe is far enough away from the foundation to prevent moisture problems

Right – The downspout terminates into a catchment system that moves water away from the foundation of the house

Right – The drain slopes away from the foundation and terminates at the proper distance

Right – The drain tile connects to a sump pump which will pump water away from the foundation

Right – The drain tile is installed along the bottom of the entire foundation footing

Right – The drain tile is wrapped in fabric which will prevent it clogging with debris

Right – The ductless minisplit in this open area is installed in the ceiling rather than on a wall.

Right – The elevator lobby of this multistory building is pressurized with outdoor air supplied to the space through this ceiling supply register.

Right – The energy rater used a window to test whole-house air leakage with this blower door testing equipment.