Showing results 151 - 200 of 265

Right – Several potential sources of air leakage into the attic have been air sealed; canned spray foam was used to seal around duct boots, along seams in the drywall, and along top plates.

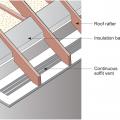

Right – Sheathing extends to rafters adding strength to soffit, baffles keep attic insulation from vent to maintain air flow

Right – Spray foam air seals and insulates the walls including the walls behind the fireplace and covers the underside of the roof deck of this mixed-dry climate home to provide an insulated attic space for HVAC ducts.

Right – Spray foam fills the roof joist cavities of this vaulted, unvented attic.

Right – Spray foam insulation is sprayed on the underside of the roof deck to provide a conditioned space in this low attic for the HVAC ducts.

Right – The top plate-to-dry wall seams of the interior walls are sealed from the attic.

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right – Wind baffle installation maintains necessary code clearance between baffle and roof deck

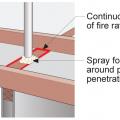

Right- This flue pipe has been air sealed with sheet metal and fire-rated caulk and an insulation dam has been constructed to keep insulation from touching the hot flue pipe

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Right: Ducts are completely buried beneath insulation to the depth specified in the plans

Right: ductwork is fully encapsulated with ccSPF prior to ceiling installation and burial

Right: Ductwork is installed in direct contact with lower truss cords. In this picture the main trunk is laying on the truss cords and branch ducts are temporarily held with strapping across truss cords. Ducts are well sealed with mastic

Roof decking has adhered radiant barrier that is perforated, in addition to the nail holes

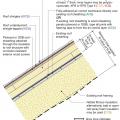

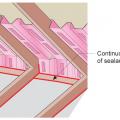

Seal the drywall to top-plate seams and the lower edge of baffles to the top plate to prevent the air coming from soffit vents from flowing under baffles into insulation.

Second layer of rigid insulation is adhered with foam

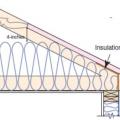

Sloped roof with cavity spray foam insulation sprayed on underside of roof deck and covered with sprayed-on thermal or ignition barrier coating.

Sloped roof with cavity spray foam insulation, strapping, and gypsum board thermal barrier

Southern Energy Homes worked with DOE researchers to develop an efficient way to dense-pack blown fiberglass into the low attics of manufactured homes.

Spray foam insulates and air-seals the ceiling deck and top plates of this vented attic.

Spray foam insulation insulates and air seals around plumbing pipes and top plates in the attic.

Spray foam insulation is applied along the underside of the roof deck to provide a conditioned and non-vented attic space for ducts and air handlers.

Spray foam insulation used for raised ceiling duct chase

Spray foam insulation used for raised ceiling duct chase.

Spray foam insulation was installed on the underside of the roof deck and on gable end attic walls to create an unvented attic

Standard 2 in. by 4 in. stud secures duct chase - made of rigid insulation in this example

Standard roof trusses are narrow at the eaves, preventing full insulation coverage over the top plate of the exterior walls

Stuff cavities under kneewalls with rolls of fiberglass batt and spray foam in place

The attic duct chase insulated and sealed to the attic floor with spray foam

The attic is insulated along the underside of the roof deck with 8 inches of open-cell spray foam.

The attic knee walls were constructed from 2x6s and insulated with R-19 batt, backed with 1 inch of XPS foam board with taped joints to provide a solid air barrier over the insulated surfaces.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The builder installed this OSB under the roof rafters and air sealed the seams with tape then added a dropped drywall ceiling to provide a service cavity for ducts and wiring, while minimizing holes into the attic.

The builders sprayed the underside of the roof assembly with 6 inches of open-cell spray foam to create an unvented, R-48 insulated attic.

The drywall above the dropped ceiling duct chase extends beyond adjoining top plates for a continuous air barrier

The enhanced comfort attic insulation consists of an ultra-efficient 25-inch-thick layer of blown cellulose providing a substantial R-90 insulation value.

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

The green framing is lumber that was pressure treated with borate to increase its resistance to termites, mold, and moisture

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The polyethylene ceiling vapor barrier is sealed to form an air barrier around the exhaust fan in this very cold climate location (≥ CZ 6).