Showing results 51 - 82 of 82

Right – Closed-cell polyurethane foam is sprayed on the underside of the roof deck to provide structural connections and seal seams in the sheathing to increase wind resistance

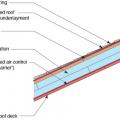

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

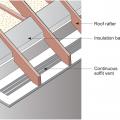

Right – Sheathing extends to rafters adding strength to soffit, baffles keep attic insulation from vent to maintain air flow

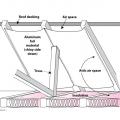

Roof decking has adhered radiant barrier that is perforated, in addition to the nail holes

Sloped roof with cavity spray foam insulation sprayed on underside of roof deck and covered with sprayed-on thermal or ignition barrier coating.

Sloped roof with cavity spray foam insulation, strapping, and gypsum board thermal barrier

Spray foam insulation is applied along the underside of the roof deck to provide a conditioned and non-vented attic space for ducts and air handlers.

Spray foam insulation was installed on the underside of the roof deck and on gable end attic walls to create an unvented attic

The green framing is lumber that was pressure treated with borate to increase its resistance to termites, mold, and moisture

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The polyethylene ceiling vapor barrier is sealed to form an air barrier around the exhaust fan in this very cold climate location (≥ CZ 6).

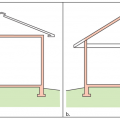

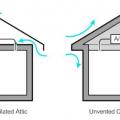

The thermal boundary for a gable roof can be located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

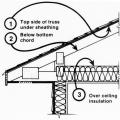

The ventilation space in this vented over-roof keeps the roof cool to prevent ice dams over the unvented attic

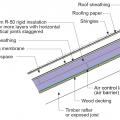

There are three potential locations for an attic radiant barrier – adhered to the underside of the roof decking, hanging from the rafters, or on the ceiling insulation

This finished retrofit installation of radiant barrier in attic shows the air spaces at the soffit and ridge to promote attic ventilation

Three locations and methods for installing a roof deck radiant barrier in new construction

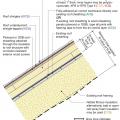

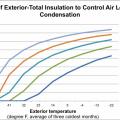

To reduce the risk of condensation on the interior of the roof sheathing in cold weather, the ratio of exterior (above-deck) insulation must be increased as a percent of total attic insulation as outside temperature decreases

Underneath the roof sheathing and two exterior layers of rigid foam, the builder stapled netting to the underside of the rafters and filled the roof cavities of the unvented attic with blown-in fiberglass insulation.

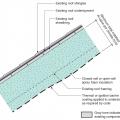

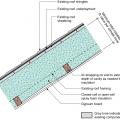

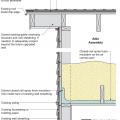

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and a fully adhered membrane seal at the top of wall-to-roof transition

Unvented roof assembly at rake retrofitted with a filler piece and taped top edge of existing house wrap or building paper to seal the top of wall-to-roof transition

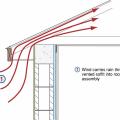

Vented roof assembly at eave retrofitted with rigid foam, spray foam, and fully adhered membrane to air seal the top of wall-to-roof transition

Vented roof assembly at rake retrofitted with spray foam and additional insulation installed at the attic floor and extended to the rake edge

Wrong – Gable end vents can circumvent soffit-to-ridge airflow and allow in wind-driven rain and wildfire embers

Wrong – Roof underlayment is not fully adhered and roof deck seams are not sealed so roof is susceptible to high-wind events

Wrong – The open overhang with exposed timbers and unscreened vent holes make this roof more susceptible to ignition.

Wrong – This house under construction is lacking wall to truss bracing and the bottom chord of the scissor trusses is several feet above the top of the end wall top plate

Wrong – Wind-driven rain and wildfire embers can enter an attic through the soffit vents.

Wrong: Closed-cell spray foam roof insulation was not thick enough to meet IRC levels so the foam surface is colder than the dew point of the interior air and condensation formed on surface of the foam