Showing results 401 - 450 of 733

Right – Chase capped with rigid air barrier and duct work penetrations properly sealed

Right – Closed-cell spray foam insulates and air-seals the rim joist above a shared wall between the garage and living space.

Right – Closed-cell spray foam insulation in the shared wall between the garage and living space helps to air-seal the wall and protect occupants from garage pollutants.

Right – Coated OSB provides a weather-resistant air barrier for this envelope of this home.

Right – Even house wrap is installed in the factory for these modular homes where each floor is factory assembled.

Right – Every seam and nail hole in these garage-to-house walls is sealed with tape.

Right – Fan with a cleanly cut and properly sized hole has been air sealed to drywall

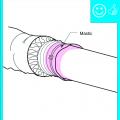

Right – Flex duct is properly connected to metal duct with a duct tie and connection is mastic sealed

Right – Interior wood-to-wood seams around a window are sealed with tape to prevent air leakage.

Right – Joists between floors are air sealed to the ceiling drywall with canned spray foam along each joist-to-drywall-seam.

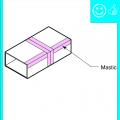

Right – Metal or fiberboard duct is mastic sealed at junction with duct register box

Right – Several potential sources of air leakage into the attic have been air sealed; canned spray foam was used to seal around duct boots, along seams in the drywall, and along top plates.

Right – Some tape is pressure sensitive; a roller is used to apply even pressure to ensure full adhesion.

Right – Spray foam insulates the walls and ceilings separating the garage from the home.

Right – Spray foam is used to carefully seal behind plumbing that was installed in an exterior wall.

Right – Spray foam was installed at the sheathing intersection as well as the sill plate to sub-floor connection.

Right – Tape and spray foam are used to air seal around pipes that extend through exterior walls.

Right – the 2x6 walls are insulated with a flash-and-batt approach that includes spraying the wall cavities with one inch of open-cell foam to seal the sheathing to the framing then filling the wall cavities with R-19 fiberglass batts that are compressed

Right – The air- and water-barrier material lining the shower stall is mastic sealed to prevent leakage and rigid foam insulation is installed on the floor of the shower.

Right – The base of the wall is water proofed and the seam between the base of the wall and the sidewalk is air sealed.

Right – The builder constructed a mock up of the wall assembly for this multi-family building.

Right – The energy rater used a window to test whole-house air leakage with this blower door testing equipment.

Right – The exhaust fan duct is sealed to the fan with mastic and the fan opening is covered with cardboard to keep out dust during construction.

Right – The hard metal ducts are located in conditioned space between floor joists and all seams are sealed with approved metal tape.

Right – The insulating enclosure over this non-IC rated recessed light fixture is centered and air sealed

Right – The joint between the foundation wall and the mud sill is thoroughly sealed with a liquid-applied sealant.

Right – The PEX piping and sink drain of this bathroom sink are fitted with escutcheons that help to air seal around the pipes and prevent pest entry.

Right – The rim joists above the pre-insulated basement walls are sealed and insulated with spray foam to prevent air leakage at this juncture in the building envelope.