Showing results 501 - 733 of 733

Seal all penetrations through the band joist

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant along top edge of chase framing

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant on top edge of chase framing

Seal bottom layer of rigid insulation with adhesive, tape and nails

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

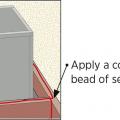

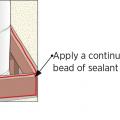

Seal the crack between the sill plate and the foundation wall

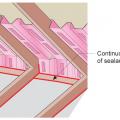

Seal the drywall to top-plate seams and the lower edge of baffles to the top plate to prevent the air coming from soffit vents from flowing under baffles into insulation.

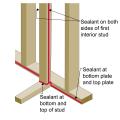

Sealant is installed to air seal along the top and bottom plates of exterior walls and along both sides of the first interior stud on intersecting interior walls

Second layer of rigid insulation is adhered with foam

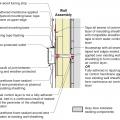

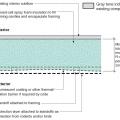

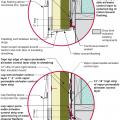

Section view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Section view of electric box installation in exterior wall showing flashing and air sealing details

SIP wall and roof panels can be sealed at all seams with a tenacious air sealing tape.

Smoke generators are used to identify air leakage sites during depressurization testing

Spray foam insulates and air-seals the ceiling deck and top plates of this vented attic.

Spray foam insulates the top plates and air seals them to the ventilation baffles before ceiling drywall is installed.

Spray foam insulation air-seals and insulates the floor above the garage; the joist will be filled with fibrous insulation in this flash-and-batt approach.

Spray foam insulation insulates and air seals around plumbing pipes and top plates in the attic.

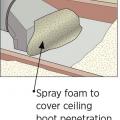

Spray foam insulation used for raised ceiling duct chase

Spray foam insulation used for raised ceiling duct chase.

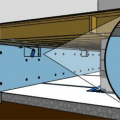

Spray foam provides a critical seal between the subfloor, rim joist, and sill plate

Sprayer-applied sealant seals every seam in the sheathing and framing of this double-walled home.

Taped plywood creates a continuous sheathing layer while cork adds a layer of continuous insulation to the outside of the wall.

The application of intumescent coating/protection layer protects this elevated floor system from below.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The builder installed this OSB under the roof rafters and air sealed the seams with tape then added a dropped drywall ceiling to provide a service cavity for ducts and wiring, while minimizing holes into the attic.

The ceiling and sides of this corridor service chase in a multifamily building are air-sealed with mudded and taped drywall prior to installing pipes, wiring, and ducts.

The ceiling and sides of this service corridor in a multifamily building are air-sealed with mudded and taped drywall prior to installing pipes, wiring, and ducts.

The ceiling over an unconditioned space is insulated with closed-cell spray foam that fills the ceiling cavities and encapsulates the framing

The duct sealing spray injection system application tunnel inflates as the injection system operates

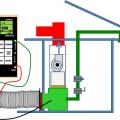

The duct sealing spray injection system includes a blower/heater (background) and the sealant injection unit (foreground)

The home is sheathed with rigid foam insulation and all seams and holes are taped to provide a continuous air barrier.

The hoses on this manometer are correctly connected with the red hose connected for the house with reference to outside and the green hose connected for the fan with reference to the house for a blower door test to show air leakage by pressure differences

The I-joist is continuous along the shared wall and serves as a natural air barrier between the garage and the house

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The original corner seam is air-sealed with caulk, then rigid foam is installed on the existing garage ceiling and walls, and finally covered with drywall.

The party wall interfaces of this multifamily building are sealed with air-sealing tape

The polyethylene ceiling vapor barrier is sealed to form an air barrier around the exhaust fan in this very cold climate location (≥ CZ 6).

The rigid air barrier behind the tub is air sealed where the sheet good meets adjoining walls, on any seams in the air barrier sheathing, and between the drywall and framing on both sides of the tub

The rough opening around this window is air sealed and insulated with nonexpanding spray foam.

The seams in the plywood are taped seams in the cathedral ceiling serve as part of the advanced home sealing strategy.

The tape is applied with even pressure to ensure the seams in the rigid foam sheathing are air sealed on this manufactured home.

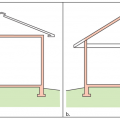

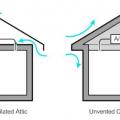

The thermal boundary for a gable roof can be located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

This aerosol sealant process seals off small leaks in the building envelope with tiny particles of nontoxic acrylic sealant that are sprayed into the air while the home is pressurized with a blower door kit.

This air-sealing approach uses the wall drywall to isolate the corridor from the individual units in a multifamily building that has a truss floor structural system

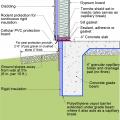

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This builder applied an air-sealing layer of spray foam along the underside of the roof deck and the inside of the walls before filling the wall cavities with blown cellulose.

This digital manometer contains a pressure transducer used to determine pressure differences or flow rate for measuring air leakage in ducts; it is showing 72.92 cfm of leakage at 25 Pascals of depressurization of the ducts.

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

This manometer is set up to show whole house air leakage with reference to the outside during a blower door test; the reading is showing 1,434 cfm of leakage when the home is depressurized to about 50 Pascals.

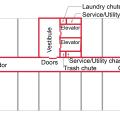

This plan view shows compartmentalization of one floor of a multistory multifamily building; red lines are air barriers around vertical shafts and common areas; grey lines are air barriers between units; vestibules isolate elevators from corridors

This typical dropped ceiling hallway chase shows a complicated air sealing scheme where chase ceiling drywall meets sidewall top plates

Thorough air sealing is one way the Habitat for Humanity affiliate in Loudon County, FL, improves the efficiency and weather resistance of its homes.

To minimize air leakage through electrical boxes, the boxes were either wrapped with fire-resistant putty (required at fire-rated walls) or wire penetrations were foamed and the boxes were caulked to the drywall.

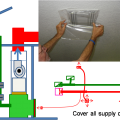

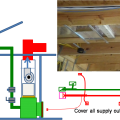

To prepare for a total duct test at final, cover all of the supply outlets and return inlets

To prepare for a total duct test at rough-in, cover all of the supply outlets and return inlets

To seal a partition wall at the floor-exterior wall junction: a. install self-adhered membrane over subfloor, rim joist, and partition wall; b. construct walls of next floor, install more flashing over first flashing and up partition wall

Typical installation of a double section modular home on a pier and ground anchor foundation

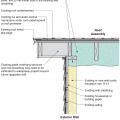

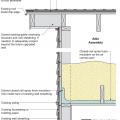

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and a fully adhered membrane seal at the top of wall-to-roof transition

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and taped top edge of existing house wrap or building paper

Unvented roof assembly at rake retrofitted with a filler piece and taped top edge of existing house wrap or building paper to seal the top of wall-to-roof transition

Unvented roof assembly at rake retrofitted with spray foam installed along the underside of the roof deck and extended to the rake edge to insulate and air seal the attic

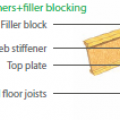

Use caulk or spray foam to air-seal all four edges of the blocking material in each joist bay.

Use masking tape as a removable sealer to stop air from leaking around the return grille filter.

Vented roof assembly at eave retrofitted with rigid foam, spray foam, and fully adhered membrane to air seal the top of wall-to-roof transition

Vented roof assembly at rake retrofitted with spray foam and additional insulation installed at the attic floor and extended to the rake edge

Ventilation air comes directly from outdoors, not from adjacent dwelling units, garages, crawlspaces, or attics

Vertical service shafts and trash chutes are isolated from corridors in multistory buildings by locating them within the vestibules

When architects and builders think of the house as a systems, all of the parts are designed to work together for a healthy, durable home that minimizes builder callbacks while cutting energy, maintenance, and repair costs down the road.

When using I-joists, make sure to fill in the gaps on each side of the blocking material to air-seal the joist bay where a wall separates conditioned and unconditioned spaces.

When wiring is installed in ICF walls, openings made for wire runs should be air-sealed with caulk.

Where the interior wall intersects the corridor wall in this multifamily building, the first intersecting wall stud is sealed to the corridor wall along both sides; other seams and penetrations in the exterior wall are also sealed

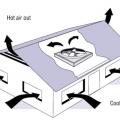

Whole house fans draw cool night-time air in through open windows and expel hot house air into the vented attic

Wire hardware mesh is fastened with a staple gun and screws to the wall to prevent pests from entering the building through small holes and cracks

Wrong - Batt insulation does not provide complete coverage across the attic floor so ceiling joists are exposed resulting in thermal bridging.

Wrong - Cantilevered joist bay cavities are not air sealed with a solid air barrier, allowing outside air to flow between floors.

Wrong - Dark pattern on wall is showing where warm air is leaking into the wall cavity from interior of home.

Wrong - Dark patterns on the Home's exterior siding show where warm air is leaking into the wall cavities.

Wrong - Duct seams were sealed with regular duct tape which has failed to hold; seams should have been sealed with mastic or approved metal tape.

Wrong - Flex duct insulation is overly compressed in 3 ways; Zip-tie fastener is over the insualtion not under the insulation at the duct boot collar, duct turning radius is too tight, and support strap is too tight.

Wrong - Foil air barrier was ripped to install wiring; foil should be replaced with a solid air barrier and wiring hole should be caulked.

Wrong - Hole around electrical box is cut too large; gap needs to be air-sealed.

Wrong - Hole in rim joist was cut too large for plumbing pipe and the gaps are not air sealed.

Wrong - Holes in rim joists were cut too large for plumbing pipes and gaps should be air sealed.

Wrong - HVAC duct and flue are too close to wall and will be difficult to properly air seal and insulate around when ceiling is installed.

Wrong - HVAC rigid metal duct seam needs to be air sealed with mastic or metal tape.

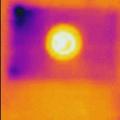

Wrong - IR image shows a lack of air-sealing and insulation around a ceiling light fixture.

Wrong - Membrane or sealant air seal is missing at the intersection of the party wall with the exterior wall in this multifamily building

Wrong - Metal tape is poorly adhered and metal duct and duct-to-subfloor seam is not sealed.

Wrong - Penetrations in walls for ducts should be air sealed to reduce air leakage.

Wrong - Plumbing penetrations are not sealed in sub-floor and it is not recommended to run plumbing in a cantilevered floor.

Wrong - Rigid insulation blocking is installed but not air-sealed with spray foam around edges.

Wrong - Tape is not well adhered to house wrap and wiring penetration is not sealed.

Wrong - The caulk is too far from the sill plate to effectively air-seal the gap.

Wrong - The faced batt insulation does not provide an air barrier in the joist bay between the garage and the conditioned space of the home.

Wrong - The opening in the foundation wall around this pipe has not been sealed allowing entry for rodents and bugs

Wrong - The seam around the duct boot where the duct boot enters the trunk duct has not been completely sealed with mesh tape and mastic.

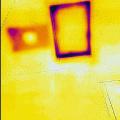

Wrong - This IR image is showing a lack of air-sealing is allowing cold air to enter the home around the windows and at the base of the wall.

Wrong - This IR image is showing that cold air is entering the home at the window frame and the sill plate at the base of the wall.

Wrong - This IR image shows a lack of air-sealing around the door, window, and light switch that is allowing in cold air.

Wrong - This is a poorly sealed chase with no solid air barriers along the sides of the chase and no caulk around the electrical wires installed through the ceiling of the chase.

Wrong - This plumbing penetration through the foundation wall has not been sealed; the seam between the sill plate and the foundation wall is also unsealed

Wrong - Tub or shower floor is not insulated and air-sealed with a solid barrier material between the floor joists and the tub. Plumbing pipes shouldn't be located in a cantilever.

Wrong - Unsealed holes for pipes can leave gaps large enough for insects, rodents, and even birds to enter the home.

Wrong - Vent hole has no cover or screening and is poorly sealed and flashed to siding.

Wrong - Vent hole has no cover or screening and is poorly sealed and flashed to siding.

Wrong - Wall cavities behind shower are not completely filled with insulation and are lacking the solid interior air barrier.

Wrong - When ceiling joists over a garage run perpendicular to the adjoining wall, the joist bays must be blocked and sealed to prevent garage fumes from entering the living space

Wrong – An opportunity to use structural members as a natural air barrier was missed in this home and blocking was not initially planned for between the garage and living space.

Wrong – Duct is pulling away from ceiling because it is not sealed to the ceiling

Wrong – Fiber board duct is not sealed at seams; flex duct is sealed with duct tape not mastic tape or UL-181 metal tape.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used to air-seal openings.

Wrong – Foam was sprayed at exterior sheathing and sill plate connection, leaving gaps beneath sill plate.

Wrong – Holes have been cut larger than needed, making them difficult to air-seal.

Wrong – If a wall vapor retarder is needed, as in this cold-climate home, openings in the vapor retarder should be sealed with tape.

Wrong – Insulation is in direct contact with this non-insulation contact (IC)-rated recessed light fixture

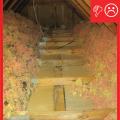

Wrong – No blocking installed to prevent attic insulation from falling into stairs and opening

Wrong – No membrane or sealant is installed to air seal at the roof-truss assembly junction with the party walls

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – Seams in the furnace-to-AC connection at the air handler are not sealed.

Wrong – The blower door is installed improperly with a gap at the corner and along the side of the frame that will allow air leakage and could allow the frame apparatus to become dislodged during testing

Wrong – the interior seam of the branch duct to trunk duct juncture is sealed with mastic but there are gaps around the exterior seam that should also be sealed with mastic or metal tape.

Wrong – the sheathing tape is properly installed to cover all seams in the coated sheathing but the flexible sill flashing product is not consistently installed or fully adhered around the window sills and is missing or lapped at some corners.

Wrong – There is no foam gasket or air-sealing between the sill plate and masonry foundation.

Wrong – There is visible light around the door because no weather stripping has been installed.

Wrong – These holes have been cut larger than needed, making them difficult to seal.

Wrong – These plumbing penetrations have been cut larger than needed, making them difficult to seal.

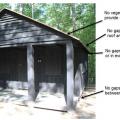

Wrong – This cabin has a gap between the concrete slab and the wall where rodents can enter

Wrong – This electric wiring hole was filled with foam that is not protected with copper mesh or hardware cloth so rodents could chew through the foam and enter the house (see Solution Center Guide "Reduce Pest Intrusion").

Wrong – This metal duct is crushed, is sealed with duct tape instead of mastic or UL-181 metal tape, and is not correctly supported.

Wrong – When insulating with spray foam, care should be taken to completely fill areas around piping and other penetrations to avoid leaving air gaps.

Wrong – Where possible, design walls and specify window sizes and placement to minimize the use of studs around windows; and seal all wood-to-wood seams to minimize air leakage through walls.

Wrong – Whole house fan installed with holes in surrounding platform that need to be air sealed

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).

Wrong: Open wall cavities in the un-air-sealed return plenum connect the plenum to attic spaces

Wrong: open wall cavity connected to this return air plenum is allowing cellulose attic insulation to be pulled into the furnace

Wrong: The door and filter were removed, allowing unfiltered air to enter the air handler leading to premature failure of the system due to dirt accumulation.

Wrong: The return plenum is not air sealed to separate it from the wall cavities and it should not be used for storage

Wrong: This return air plenum is not lined and air sealed

Wrong: This wall cavity is open to the attic allowing unconditioned, attic air to enter the HVAC system, bypassing the filter, and degrading system life and performance