Showing results 1 - 100 of 106

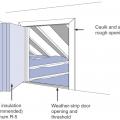

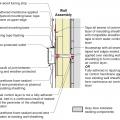

A piece of siding is used as sill extension and to provide slope in the opening for the window, which is deeper because exterior rigid foam has been added

Air seal around all duct shafts and flues installed through ceilings, walls, or flooring to keep conditioned air from leaking into unconditioned space.

Air seal around kitchen and bathroom exhaust fans to keep conditioned air from leaking into unconditioned space.

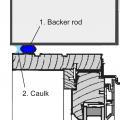

Air seal door and window rough openings with backer rod, caulk, or nonexpanding foam

Air seal duct boot to ceiling by installing fiberglass mesh tape and mastic over seam

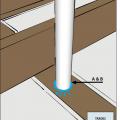

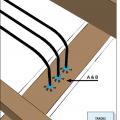

Air-seal around all plumbing and piping installed through walls, ceilings, and flooring adjacent to unconditioned space to prevent air leakage.

Air-seal around all wiring installed through walls, ceilings, and flooring to keep conditioned air from leaking into unconditioned space.

Air-seal around recessed can light fixtures that are installed through ceilings to keep conditioned air from leaking into unconditioned space.

Closed-cell backer rod is installed for air-sealing window and door rough openings.

Duct boot is air sealed to ceiling by covering the seam with fiberglass mesh tape and mastic

Fiberglass mesh tape is installed around a duct boot in preparation for air sealing with mastic

Install an ENERGY STAR labeled insulated door with an automatic closer. Weather strip the door frame

Install mesh insect barrier along the tops and bottoms of the rain screen behind the exterior cladding of above-grade walls.

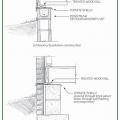

Install termite shields and use solid concrete or filled concrete block for the top of foundation walls to deter termites and other pests

Light tubes adjacent to unconditioned space include lens separating unconditioned and conditioned space and are fully gasketed

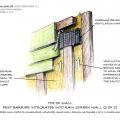

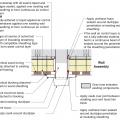

Plan view of duct or pipe penetration through exterior wall showing flashing and air sealing details

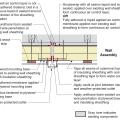

Plan view of electric box installation in exterior wall showing flashing and air sealing details

Reinforce concrete slab and foundation walls to minimize future cracks that could let in pests

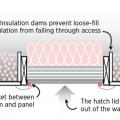

Right - The attic access panel is insulated and weather stripped and a dam is built to hold back the blown attic floor insulation

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The water and air control layers are properly integrated around the hose bib

Right - This ceiling-mounted mini whole-house fan has built-in insulated covers to reduce heat loss when the fan is not in use

Right - This duct penetration is properly flashed and integrated with the taped, foil-faced foam sheathing layer, which serves as the air and water barrier

Right - This opening in the foundation wall around this pipe was filled with wire mesh then sealed with spray foam to prevent rodent and insect entry

Right – Attic access hatch has been properly insulated by attaching a fiberglass batt, gasketed, and opening has blocking

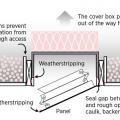

Right – Attic access door has foam and rubber weatherstripping installed that remains in contact when closed.

Right – Backer-rod is a foam product available in various diameters that can be used to air-seal openings around doors and windows.

Right – Blocking has been installed around the perimeter of this attic access to prevent insulation falling into the house

Right – Chase capped with rigid air barrier and duct work penetrations properly sealed

Right – Fan with a cleanly cut and properly sized hole has been air sealed to drywall

Right – The rough opening around the window has been filled with low-expansion foam to air seal.

Right – The rough opening around window has been filled with backer-rod to air seal.

Right – This ICAT recessed light is sprayed with foam to act as gasket against the drywall.

Right – Weatherstripping has been installed and remains in contact when the door is closed.

Right: Refrigerant piping is sealed where it exits the return plenum

Seal all penetrations through the band joist

Section view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Section view of electric box installation in exterior wall showing flashing and air sealing details

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

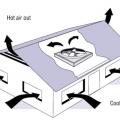

Whole house fans draw cool night-time air in through open windows and expel hot house air into the vented attic

Wire hardware mesh is fastened with a staple gun and screws to the wall to prevent pests from entering the building through small holes and cracks

Wrong - The opening in the foundation wall around this pipe has not been sealed allowing entry for rodents and bugs

Wrong - This plumbing penetration through the foundation wall has not been sealed; the seam between the sill plate and the foundation wall is also unsealed

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Fibrous insulation is not an air barrier and cannot be used to air-seal openings.

Wrong – Holes have been cut larger than needed, making them difficult to air-seal.

Wrong – No blocking installed to prevent attic insulation from falling into stairs and opening

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – Roughly cut hole that is larger than the fan, making it difficult to seal

Wrong – There is visible light around the door because no weather stripping has been installed.

Wrong – These holes have been cut larger than needed, making them difficult to seal.

Wrong – These plumbing penetrations have been cut larger than needed, making them difficult to seal.

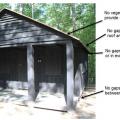

Wrong – This cabin has a gap between the concrete slab and the wall where rodents can enter