Showing results 1 - 28 of 28

Air-seal around all wiring installed through walls, ceilings, and flooring to keep conditioned air from leaking into unconditioned space.

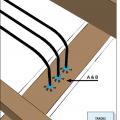

Plan view of electric box installation in exterior wall showing flashing and air sealing details

Right - Electrical box in exterior wall is completely sealed with liquid flashing.

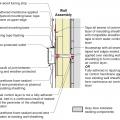

Right - External outlet wall penetration is flashed with tape that is properly layered with house wrap.

Right – A flexible tape is used to air-seal around wiring holes in the coated sheathing.

Right – All electrical boxes are carefully sealed as are all top plate-to-drywall seams.

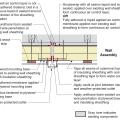

Section view of electric box installation in exterior wall showing flashing and air sealing details

To minimize air leakage through electrical boxes, the boxes were either wrapped with fire-resistant putty (required at fire-rated walls) or wire penetrations were foamed and the boxes were caulked to the drywall.

When wiring is installed in ICF walls, openings made for wire runs should be air-sealed with caulk.

Wrong - Hole around electrical box is cut too large; gap needs to be air-sealed.

Wrong - HVAC duct and flue are too close to wall and will be difficult to properly air seal and insulate around when ceiling is installed.

Wrong - Tape is not well adhered to house wrap and wiring penetration is not sealed.

Wrong - This is a poorly sealed chase with no solid air barriers along the sides of the chase and no caulk around the electrical wires installed through the ceiling of the chase.

Wrong – Fibrous insulation is not an air barrier and cannot be used for sealing holes.

Wrong – Holes have been cut larger than needed, making them difficult to air-seal.