Showing results 1 - 132 of 132

A second layer of rigid insulation is installed over the 2 in. by 4 in. retaining strip

A technician assembles the spray sealant injection system to seal HVAC ducts from the inside

Air seal a heat pump or air conditioner air handler cabinet at all seams, holes, and junctions

Air seal all holes and seams in the furnace cabinet with mastic, foil tape, or putty

Air seal around all duct shafts and flues installed through ceilings, walls, or flooring to keep conditioned air from leaking into unconditioned space.

Air seal duct boot to ceiling by installing fiberglass mesh tape and mastic over seam

All of the ductwork for the efficient (8.5 HSPF, 15 SEER) heat pump is mastic sealed and installed in conditioned space.

Connect the plastic application tunnel from the injection equipment to the supply plenum.

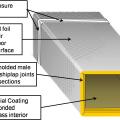

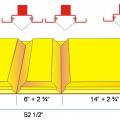

Cut fiber board with a red V-groove tool and a gray shiplap tool to create mitered corners and a shiplapped edge for duct sections

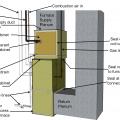

Cut-away view showing unsealed gaps around a heating duct that goes through a wall

Duct boot is air sealed to ceiling by covering the seam with fiberglass mesh tape and mastic

Duct boots sealed to floor, wall, or ceiling using caulk, foam, mastic tape, or mastic paste

Fiberglass mesh tape is installed around a duct boot in preparation for air sealing with mastic

Hand tools for cutting fiber board sheets include a knife, straight edge, and color-coded edge-cutting tools

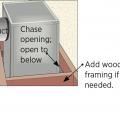

Install wood framing cross pieces in the attic rafter bays on each side of the duct chase

Plan view of duct or pipe penetration through exterior wall showing flashing and air sealing details

Prepare chase with adhesive for bottom insulation

Raised ceiling chase sealed with drywall mud

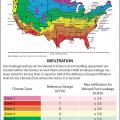

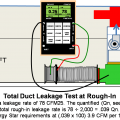

Rater-measured duct leakage to outdoors ≤ 4 CFM25 per 100 sq. ft. of conditioned floor area

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - This duct penetration is properly flashed and integrated with the taped, foil-faced foam sheathing layer, which serves as the air and water barrier

Right – A contractor installs mastic in branch duct take offs to air seal the seams where they attach to the trunk duct.

Right – Chase capped with rigid air barrier and duct work penetrations properly sealed

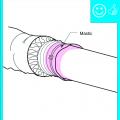

Right – Flex duct is properly connected to metal duct with a duct tie and connection is mastic sealed

Right – Metal or fiberboard duct is mastic sealed at junction with duct register box

Right – The hard metal ducts are located in conditioned space between floor joists and all seams are sealed with approved metal tape.

Right – This supply duct is thoroughly sealed at all joints with mastic to prevent air leakage and the duct is equipped with a damper to provide zoned heating and cooling along with other trunk ducts.

Right: A well-constructed air handler closet

Right: Air seal all seams in the return air plenum before installing a new air handler

Right: Refrigerant piping is sealed where it exits the return plenum

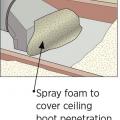

Right: Spray foam air seals and insulates raised ceiling duct chase

Right: The bottom of the air handler cabinet is well sealed to the return platform

Right: The plenum liner is well sealed to the filter-backed grille

Right: Use mastic to air seal the return air plenum and to seal around refrigerant lines coming from the slab in the floor of the return

Run-out duct is sealed with mastic

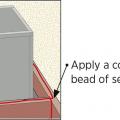

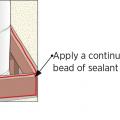

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant along top edge of chase framing

Seal all wood framing joints surrounding the chase with sealant and lay a bead of sealant on top edge of chase framing

Seal bottom layer of rigid insulation with adhesive, tape and nails

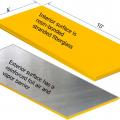

Seal seams in fiber board ducts with out-clinching staples, UL-181A-approved tape, and mastic

Second layer of rigid insulation is adhered with foam

Spray foam insulation used for raised ceiling duct chase

Spray foam insulation used for raised ceiling duct chase.

The duct sealing spray injection system application tunnel inflates as the injection system operates

The duct sealing spray injection system includes a blower/heater (background) and the sealant injection unit (foreground)

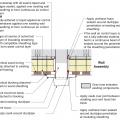

This typical dropped ceiling hallway chase shows a complicated air sealing scheme where chase ceiling drywall meets sidewall top plates

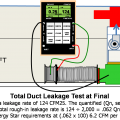

To prepare for a total duct test at final, cover all of the supply outlets and return inlets

To prepare for a total duct test at rough-in, cover all of the supply outlets and return inlets

Use masking tape as a removable sealer to stop air from leaking around the return grille filter.

Wrong - Duct seams were sealed with regular duct tape which has failed to hold; seams should have been sealed with mastic or approved metal tape.

Wrong - Flex duct insulation is overly compressed in 3 ways; Zip-tie fastener is over the insualtion not under the insulation at the duct boot collar, duct turning radius is too tight, and support strap is too tight.

Wrong - Metal tape is poorly adhered and metal duct and duct-to-subfloor seam is not sealed.

Wrong - Penetrations in walls for ducts should be air sealed to reduce air leakage.

Wrong - The seam around the duct boot where the duct boot enters the trunk duct has not been completely sealed with mesh tape and mastic.

Wrong - This is a poorly sealed chase with no solid air barriers along the sides of the chase and no caulk around the electrical wires installed through the ceiling of the chase.

Wrong – Duct is pulling away from ceiling because it is not sealed to the ceiling

Wrong – Fiber board duct is not sealed at seams; flex duct is sealed with duct tape not mastic tape or UL-181 metal tape.

Wrong – the interior seam of the branch duct to trunk duct juncture is sealed with mastic but there are gaps around the exterior seam that should also be sealed with mastic or metal tape.

Wrong – This metal duct is crushed, is sealed with duct tape instead of mastic or UL-181 metal tape, and is not correctly supported.

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).

Wrong: Open wall cavities in the un-air-sealed return plenum connect the plenum to attic spaces

Wrong: open wall cavity connected to this return air plenum is allowing cellulose attic insulation to be pulled into the furnace

Wrong: The door and filter were removed, allowing unfiltered air to enter the air handler leading to premature failure of the system due to dirt accumulation.

Wrong: The return plenum is not air sealed to separate it from the wall cavities and it should not be used for storage

Wrong: This return air plenum is not lined and air sealed

Wrong: This wall cavity is open to the attic allowing unconditioned, attic air to enter the HVAC system, bypassing the filter, and degrading system life and performance