Showing results 251 - 300 of 688

Properly install all water-using fixtures, equipment, and appliances such that there are no leaks.

Provide flashing and sealing integrated with the air and water control layers for vents and other roof penetrations

Rain barrels and cisterns collect rainwater for landscape irrigation.

Repair leaks and cracks, and cover holes in foundation floors and walls to minimize water and vapor entry.

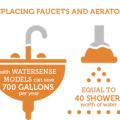

Replacing faucets and aerators with WaterSense models can save 700 gallons per year - equal to 40 showers worth of water.

Replacing your old showerhead with a new low-flow showerhead can save hundreds of gallons of water each year.

Retaining walls can prevent erosion and landslides and maintain access to critical infrastructure

Retention walls, permeable pavement, french drains, drywells, and ditches all help to divert, collect, and manage the flow of stormwater on a site.

Retrofit an existing roof by installing rigid foam, new moisture and air control layers, new sheathing, and new cladding plus cavity insulation in the roof rafters to create an unvented attic

Ridges can be constructed and planted to slow the downward flow of water and stabilize slopes.

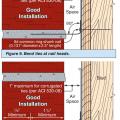

Right – The ties are bent at a 90 degree angle at the nail head and embedded into the mortar joint at least 1.5 inches.

Right – The ties are bent at a 90 degree angle at the nail head and embedded into the mortar joint at least 1.5 inches.

Right - A dimpled-plastic geotextile mat covers the below-grade insulated concrete form (ICF) foundation to help keep water out of the foundation and to reduce hydrostatic pressure on the foundation during freeze-thaw cycles in winter.

Right - A lattice of 1X4 furring strips provides a ventilation gap between the decking and metal roofing for this shed roof.

Right - A moisture sensor is installed on the roof to control the sprinkler system.

Right - A second layer of flashing tape is applied over the EPDM gasket and first layer of tape at sides and top around the duct; 14 of 14.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides of the gasket are taped; 11 of 14.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides, then the top of the gasket are taped; 12 of 14.

Right - After installing the EPDM gasket around the HRV duct, the lower edge of the gasket is taped first before taping the other edges of the gasket; 10 of 14.

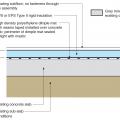

Right - Basement slab with a capillary break of either gravel or a drainage mat.

Right - Below-grade concrete has been properly sealed against moisture and is now having insulation installed.

Right - Corners of window are protected with draining house wrap that laps onto the sides of the window trim, paint-on flashing at window trim corners, and self-adhered flashing to reinforce corners.

Right - Corrugated house wrap is installed over the sheathing (in this case SIPs) and overlapped and taped at all seams.

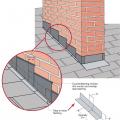

Right - Counterflashing tops a layer of step flashing which comes down above the asphalt shingle and a layer of L-shaped base flashing which comes down and extends below the shingle; the base flashing is adhered to the roof underlayment with mastic, shown

Right - Furring strips create an air gap to allow penetrating moisture to drain instead of wicking into walls; they also provide a nailing surface for siding.

Right - Here, air control is established by taping the seams of the plywood panel sheathing. The roof sheathing is also trimmed flush with the wall sheathing to allow a simple and airtight connection between the roof and wall assemblies

Right - House wrap is lapped back over first layer of flashing tape, then a second layer of flashing tape is applied to the sides around the duct; 13 of 14.

Right - House wrap is overlapped “shingle” style to direct moisture down and away from the house; seams will be taped so house wrap serves as both an air and weather barrier.

Right - Open-web floor and ceiling trusses provide space for ducts in conditioned space.

Right - Permeable rigid mineral wool insulation and appropriate water-management flashing details are integrated with new rigid foam siding to keep water away from the sill beam above the foundation wall

Right - Pressure reducing valves installed outside the home reduce water pressure before water is distributed to fixtures.

Right - Prevent condensation in fibrous insulation-filled basement wall cavities by installing rigid or spray foam between the frame wall and the concrete foundation wall and by not installing a Class I vapor retarder over the framed wall.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right - The air control membrane installed over the roof sheathing is continuous. It connects to the air control of the wall around the entire perimeter without interruption. The roof overhangs have been cut off to make this connection continuous

Right - The basement walls are wrapped with 3 inches of XPS rigid foam that will be taped at the seams then covered with a dimpled plastic water barrier.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The service penetration in the waterproofing membrane is well-sealed, and there is a drainage mat acting as a protective layer on the interior of the soldier piles and wood lagging.

Right - The water and air control layers are properly integrated around the hose bib

Right - These roof insulation panels are installed in multiple layers with joints offset both vertically and horizontally. The plywood nail base fastened to the roof framing holds the insulation layers together snuggly thus minimizing gaps

Right - This cedar siding is installed over furring strips which allow an air and drainage gap behind the siding.