Showing results 551 - 600 of 1073

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

Right – all seams in the rigid foam were sealed with tape before installing the wire lathe for stucco.

Right – An existing gable wall is reinforced with horizontal braces that butt up to the gable end wall and connect back to multiple trusses; retrofit studs make full contact with the wall and the compression blocks and are connected to the horizontal brac

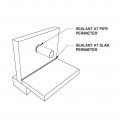

Right – Apply sealant around penetrations through foundation walls and along foundation wall seams

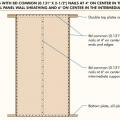

Right – Appropriate use of framing members to support double windows and additional cripples for drywall purposes

Right – Closed-cell spray foam insulation in the shared wall between the garage and living space helps to air-seal the wall and protect occupants from garage pollutants.

Right – Coated OSB provides a weather-resistant air barrier for this envelope of this home.

Right – Coated sheathing is taped at all seams to serve as an exterior air barrier on the walls.

Right – deeply inset entryways and overhangs provide shade to reduce solar heat entry to this building.

Right – Every seam and nail hole in these garage-to-house walls is sealed with tape.

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

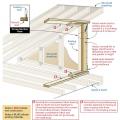

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Half-inch furring strips provide a rain screen and air gap between the weather-resistant membrane and the fiber cement siding on the exterior walls of this marine-climate home.

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

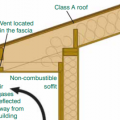

Right – In wildfire prone areas, using a flat soffit with venting on the fascia instead of an angled soffit with down-facing venting reduces the risk of catching rising embers.

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

Right – Mineral wool batt insulation is cut to fit snuggly and to fully fill wall cavities with minimal voids and gaps.

Right – Moisture-resistant backing material has been used above and behind the tub enclosure.

Right – Netted blown fiberglass insulation completely fills the wall cavities with no gaps or voids.

Right – Plumbing pipes have flanges that are sealed to the wall with caulk to prevent pest entry

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic