Showing results 101 - 150 of 192

Right – There is flashing installed along the top of the window and the water-resistant barrier is layered over to create a complete drainage system

Right – There is flashing installed at the bottom of the wall to create a satisfactory drainage system

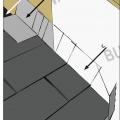

Right – This low-slope roof and parapet assembly has continuity of both the air and water barriers

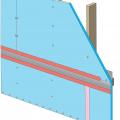

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

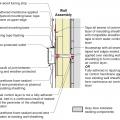

Right: Brick veneer is flashed correctly with weep holes and a fine mesh screen is installed to prevent pest entry.

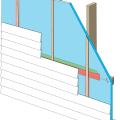

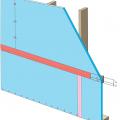

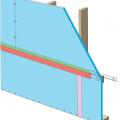

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

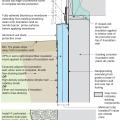

Rigid insulation and water control layers are installed on the exterior of a flat foundation wall; spray foam insulates the rim joist

Seams in the ICF block are sealed so the EPS foam surface can serve as the drainage plane; no house wrap is needed.

Section view of electric box installation in exterior wall showing flashing and air sealing details

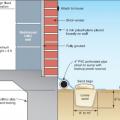

Spray foam extends down the inside of the foundation wall to the uninsulated slab; because the wall lacked exterior perimeter drainage, the slab was cut and an interior footing drain was installed.

Step 1. Apply roof underlayment over roof deck and up the sidewall over the rigid foam insulation

Step 2. Install shingle starter strip then kick-out diverter as first piece of step flashing.

Step 3. Place the first shingle and the next section of sidewall flashing over upper edge of diverter

Step 4. Install remaining sidewall flashing, appropriate counter flashing, and shingles

Step 5. Apply self-adhesive flashing over top edge of the wall flashing, diverter, and rigid foam insulation

Step and kick-out flashing at all roof-wall intersections extending ≥ 4 in. on wall surface above roof deck and integrated with drainage plane above

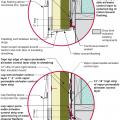

Tape horizontal joint with minimum 3" wide tape placing tape offset high on the joint, adhearing to the upper sheet without wrinkles

Tape the joint between the top insulation sheet and the Z-flashing with 2" wide tape to improve air tightness

Terminate 4" tape with 2" wide tape placing tape offset high on the joint, 2/3 of the tape should be adhered to the sheet of insulation

The sheathing has rotted because there was not a sufficient drainage gap behind the stucco cladding

The walls of this mixed-humid location home are constructed with moisture-resistant steel-framed expanded polystyrene R-34 wall panels that are designed to withstand winds up to 200 mph and level D seismic forces.

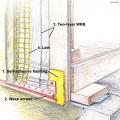

The water-resistant barrier, weep screed, and stucco lathe are not properly layered

The water-resistant barrier, weep screed, and stucco lathe are properly layered and will create a complete drainage system

The weep holes are spaced at the correct distance to provide a complete drainage system

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This farmhouse was retrofit by removing the existing siding and adding taped insulated sheathing and battens before installing new siding

This flood-resistant exterior wall with brick or fiber-cement siding will limit moisture damage in exterior walls.

This flood-resistant masonry wall design with metal framing and rigid foam insulation will limit moisture damage in exterior walls.

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

Vapor-permeable mineral wool insulation is installed on the exterior side of the sill beam during an exterior wall retrofit to allow the sill beam to dry to the outside