Showing results 51 - 100 of 192

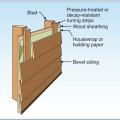

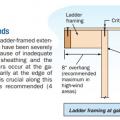

Install furring strips over house wrap to provide a rainscreen behind wood siding.

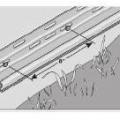

Install shingle starter strip then kick-out diverter; attach to roof deck but not sidewall

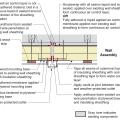

Over the taped rigid foam board, 2x4 furring strips provide a ventilating air gap and drainage plane under the engineered wood lap siding. The furring strips were attached with structural screws to provide an attachment surface for the siding.

Place first shingle and next section of sidewall flashing over upper edge of diverter

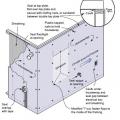

Plan view of electric box installation in exterior wall showing flashing and air sealing details

Polyethylene completely covers the floor of this crawlspace and is attached to the walls and piers as well

Polyethylene is being attached to the crawlspace floor and walls with plywood furring strips

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Right – The ties are bent at a 90 degree angle at the nail head and embedded into the mortar joint at least 1.5 inches.

Right - Basement slab with a capillary break of either gravel or a drainage mat.

Right - Below-grade concrete has been properly sealed against moisture and is now having insulation installed.

Right - Furring strips create an air gap to allow penetrating moisture to drain instead of wicking into walls; they also provide a nailing surface for siding.

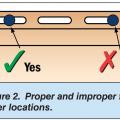

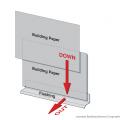

Right - House wrap is overlapped “shingle” style to direct moisture down and away from the house; seams will be taped so house wrap serves as both an air and weather barrier.

Right - Permeable rigid mineral wool insulation and appropriate water-management flashing details are integrated with new rigid foam siding to keep water away from the sill beam above the foundation wall

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Half-inch furring strips provide a rain screen and air gap between the weather-resistant membrane and the fiber cement siding on the exterior walls of this marine-climate home.

Right – Moisture-resistant backing material has been used above and behind the tub enclosure.

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – The base of the wall is water proofed and the seam between the base of the wall and the sidewalk is air sealed.

Right – The building felt is installed on all exterior walls and provides a complete drainage system

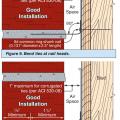

Right – The flashing is properly installed to create a complete drainage system with continuous rigid insulation sheathing/siding

Right – The insulated concrete forms that are below-grade have a damp-proof coating to prevent moisture seeping into the foundation

Right – The rigid insulation covers all exterior walls and all seams are taped to provide a complete drainage system

Right – The water-resistant barrier covers the entire house and the seams are taped to provide a complete drainage system

Right – The water-resistant barrier is layered over the step flashing to provide a complete drainage system

Right – There is a self-sealing bituminous membrane installed at the valley of the roof prior to the roof felt