Showing results 101 - 150 of 214

Right – Spray foam was installed at the sheathing intersection as well as the sill plate to sub-floor connection.

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – The sill plate was sprayed with foam prior to installation atop foundation.

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

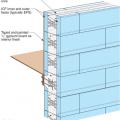

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

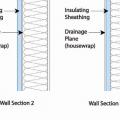

Rigid foam insulated sheathing placed exterior to house wrap, interior to house wrap, or take the place of the house wrap

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

Siding has been removed so cellulose insulation can be dense-packed into the exterior walls of this home

Single framed wall converted to double wall and insulated with closed-cell spray foam

Single framed wall converted to double wall and insulated with closed-cell spray foam and loose-fill fibrous insulation

Single framed wall converted to double wall and insulated with open-cell spray foam

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

Spray foam provides a critical seal between the subfloor, rim joist, and sill plate

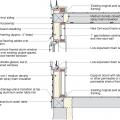

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The back dam of the window sill will force water out

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

The wall behind the fireplace is an exterior wall and requires a thermal barrier that is continuous with the rest of the wall’s insulation

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

These walls are made of autoclaved aerated concrete blocks that are lightweight, easy to cut, bug-resistant, moisture-resistant, fire-resistant and steel-reinforced to form structurally solid, air-tight, thermally resistant walls.

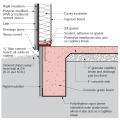

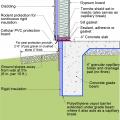

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This foundation/floor/SIP wall detail shows recommended support of SIP wall panel at the sill plate

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

This technique for installing electrical wiring avoids the need to cut into the SIP panel

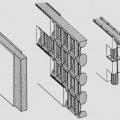

Three common ICF wall systems: the flat wall, the waffle wall, and the post-and-beam wall