Showing results 1 - 100 of 104

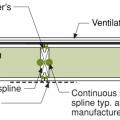

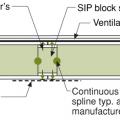

A structural spline made of a solid 2x is used where needed to meet structural load requirements at SIP panel seams

A surface spline reduces thermal bridging much more than a structural spline at SIP panel seams

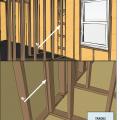

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

Advanced framing details include using the minimum amount of wall studs permitted by code.

An all-terrain forklift is used to move and stage the panels

An insulated spline is another option for avoiding thermal bridging at SIP panel seams

Construct exterior walls with insulated concrete forms (ICFs) that provide insulation without thermal bridging, as well as air sealing, a drainage plane, and high structural strength.

Construct exterior walls with structural insulated panels (SIPs) to provide an airtight wall with consistent insulation and very little thermal bridging.

Floor cavity pressure is measured by inserting a tube into the floor cavity using an extension pole

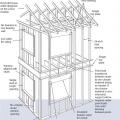

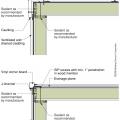

ICFs provide continuous wall insulation from the roof to the footing with very little thermal bridging

In cold climates, install slab edge insulation when pouring slab on grade foundations.

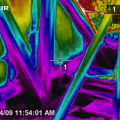

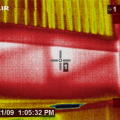

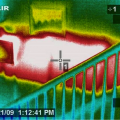

Infrared imaging shows cold conditioned air pouring out of the open floor cavities under this attic kneewall into the hot unconditioned attic

Infrared thermography during depressurization testing reveals air leakage at corner of spray foam-insulated room where wood-to-wood seams in framing were not air sealed

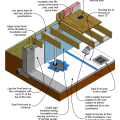

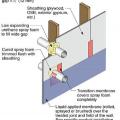

Install a housewrap drainage plane between the SIP panels and the exterior cladding

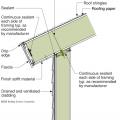

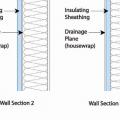

Install continuous rigid foam insulation or insulated siding to help reduce thermal bridging through wood- or metal-framed exterior walls.

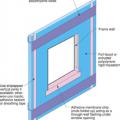

Lay out the rigid foam sheathing joints so they do not align with the window and door edges

Lifting plates attached to the wall provide good bracing to tighten up SIP panel seams

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

Make sure the beads of caulk are continuous the full length at each SIP panel seam, such as at the wall-roof seam, to maintain air barrier continuity

Peel-and-stick panel tape provides added assurance that SIP panel seams will remain airtight

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Reduce thermal bridging in hot climate zones by using an intersecting exterior wall framing technique as shown here.

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

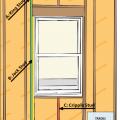

Right – Appropriate use of framing members to support double windows and additional cripples for drywall purposes

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – Rigid air barrier installed between double-wall assembly. Inside cavity will be insulated

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Rigid foam insulated sheathing placed exterior to house wrap, interior to house wrap, or take the place of the house wrap

Scaffolding is continually raised as courses of foam brick are added so that the pour man can see both sides of the wall during the pour.

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

Special molded corners provide continuous insulation layer at the corners to improve structural strength and minimize thermal bridging

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The back dam of the window sill will force water out

The floor cavities under this attic kneewall are completely open to the unconditioned attic space and a prime target for wind washing

The ICF consists of foam forms that are held in place with plastic or metal spacers and reinforced with metal rebar

Thermal bridging is eliminated at the rim joist with the use of joist ledgers that are anchored in the wall

This foundation/floor/SIP wall detail shows recommended support of SIP wall panel at the sill plate

This technique for installing electrical wiring avoids the need to cut into the SIP panel

This wall and window assembly has excessive framing around the windows, which can lead to heat gain in how climate zones.

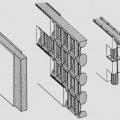

Three common ICF wall systems: the flat wall, the waffle wall, and the post-and-beam wall

Two layers of high-permeability house wrap are installed to provide a drainage layer between the SIPS and the homes external cladding

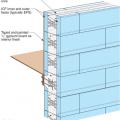

Two layers of XPS are installed with staggered seams over a liquid-applied membrane on the structural sheathing

Use a smoke pencil to check for air leaks at SIP panel seams, especially along the ridge beam

Use a truss joist header assembly as shown here to reduce thermal bridging in hot climate zones.

Use flashing tape to seal around any pipes or vents that penetrate through the foam

Utilities are commonly recessed into cutouts in the foam after concrete has been poured

Walls are being assembled at this SIP house

Window and door rough openings in the ICF wall are surrounded with pressure-treated wood

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen

Wrong – Either this tape was not pressed down firmly or the surface was wet or dirty so the tape is not sticking properly even during construction.

Wrong – If the insulated sheathing will serve as an air barrier and drainage plane, any cuts and seams must be taped or sealed.

Wrong – No air barrier installed between the walls and a larger gap between the walls that needs sealing