Showing results 1 - 59 of 59

A blower door is installed in a doorway and is ready for testing

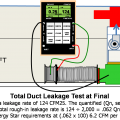

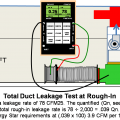

A duct leakage test is performed on a ducted heat pump system using a duct tester (blower fan) and a digital manometer.

A flow grid is inserted into the filter grille/slot to directly measure airflow.

A home is tested at two points for enclosure air leakage

A manometer is used to measure pressure differentials between indoors and outdoors when testing whole-house air leakage.

A nitrogen pressure test was completed on this ductless mini-split heat pump using a digital manifold gauge.

A static pressure measurement is taken on this air handler using probes on the supply and return sides of the fan.

A vacuum decay test is performed on this ductless mini-split heat pump using a digital micron gauge for accurate measurement; a deep vacuum is achieved quickly by using large diameter, vacuum-rated hoses, and removing valve cores

An energy rater uses a duct blower to test HVAC duct air leakage.

An infrared camera can show heat transfer and air leaks not visible to the naked eye.

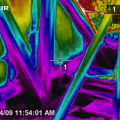

An IR camera image shows gaps around HVAC flue pipes allow conditioned air to leak through blown fiberglass into the attic

Builders use an infrared camera to “see” heat flow and air leakage around a window during construction.

Calibrated blower door fans are used for envelope leakage testing

Equipment needed to pressure test the airtightness of walls separating the house from an attached garage

Floor cavity air pressure is measured by placing a tube into the floor cavity through a small drilled hole

Floor cavity pressure is measured by inserting a tube into the floor cavity using an extension pole

Gas sensors are used for gas leak detection and carbon monoxide detection

Infrared imaging shows cold conditioned air pouring out of the open floor cavities under this attic kneewall into the hot unconditioned attic

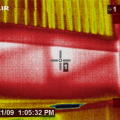

Infrared thermography during depressurization testing reveals air leakage at corner of spray foam-insulated room where wood-to-wood seams in framing were not air sealed

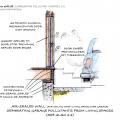

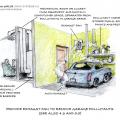

Install a self-closing door with weatherstripping and thoroughly air-seal the shared house-garage walls to help keep automobile exhaust and other pollutants out of the home.

Installing a garage exhaust fan is one important step in keeping auto exhaust and other pollutants out of the home

Limited attic access can make inspections for missing air barriers and insulation challenging

Limited attic access may make it necessary to use a bore scope when inspecting for missing air barriers and insulation in existing buildings.

Moisture levels are checked in the blown cellulose insulation before enclosing the walls.

Pressure manometers are used to determine the level of pressurization and rate of leakage when conducting blower door testing and building diagnostics

Right - Manometers are placed away from the indoor side of the fan during blower door testing

Right - This air flow testing station includes a manometer to determine air flow rate for a whole house ventilation system.

Right – An infrared image of this home shows very little heat transfer through the exterior walls.

Right – The blower door is installed snugly and securely to the door frame during testing

Right – The blower door pressure reference hose is placed well away from the outdoor side of the fan

Right – The energy rater used a window to test whole-house air leakage with this blower door testing equipment.

Right – This IR image shows very little heat loss through the home’s exterior walls.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Smoke generators are used to identify air leakage sites during depressurization testing

The air tightness of the garage-to-house air barrier can be tested with a blower door kit and two manometers

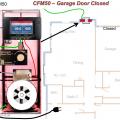

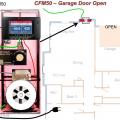

The air tightness of the house-garage air barrier can be tested using a CFM50 test that is first run with the garage door to outdoors closed

The air tightness of the house-garage air barrier can be tested using a CFM50 test that is run first with the garage door to outdoors closed and then with the overhead garage door to outdoors open

The moisture level of the cellulose wall insulation is tested with a moisture meter to verify that the insulation is sufficiently dry before installing drywall.

The moisture level of the wall studs is tested with a moisture meter to verify that the wood is sufficiently dry before installing drywall.

These ICF homes are blower door tested during construction, before the drywall is installed, when air leaks can be easily sealed.

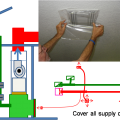

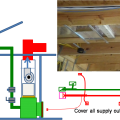

To prepare for a total duct test at final, cover all of the supply outlets and return inlets

To prepare for a total duct test at rough-in, cover all of the supply outlets and return inlets

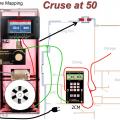

To test house-to-garage airtightness, after connecting the green tubing as shown, connect the red tubing as follows: connect the input tap on channel “A” of the two-channel manometer (2CM) to the reference tap on channel “B” of the 2CM

To test house-to-garage airtightness, first set up the blower door kit with the smart manometer in the blower door

Two manometers are used when pressure testing the airtightness of the walls separating the house from an attached garage

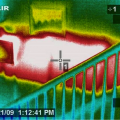

Wrong - This IR image of a second-floor landing shows that attic air is flowing far into the interstitial floor cavity of the second-floor landing

Wrong - This IR image shows where hot attic air has penetrated into the floor cavity that lies behind the stairwell wall

Wrong – The blower door is installed improperly with a gap at the corner and along the side of the frame that will allow air leakage and could allow the frame apparatus to become dislodged during testing

Wrong – The blower door pressure reference hose (blue) ends too close to the outdoors side of the fan. Air moving across the end of the hose will affect the pressure reading

Wrong – The gas water heater is left on during enclosure leakage testing, which could result in dangerous backdrafting of the water heater when the home is depressurized

Wrong – this framing material has a moisture content above 18% as shown by the moisture meter