Showing results 101 - 141 of 141

The basement is constructed with precast concrete walls lined with R-21.3 foil-faced rigid foam while an R-10 layer of XPS rigid foam covers the ground under the slab.

The basement slab is wrapped in a blanket of insulation including R-27 of closed-cell spray foam under the slab and R-22 ICF blocks wrapping the slab edges.

The builder laid down a 4-inch base of aggregate rock, then covered that with a plastic vapor barrier that is taped at all seams and around all penetrations before installing the rigid foam under-slab insulation.

The builder’s crews spray foam directly onto the ground to provide a vapor barrier and insulation layer under the slab.

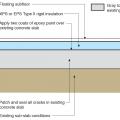

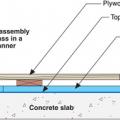

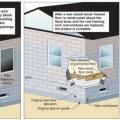

The existing slab is retrofitted by coating with epoxy paint, then installing rigid foam insulation and a floating subfloor.

The existing slab is retrofitted with epoxy paint, rigid foam insulation, sleepers (furring strips), and subfloor.

The floor slab is completely insulated with ICF foundation walls and R-20 (3 inches) of closed-cell foam that is sprayed directly onto the ground before pouring the slab.

The foundation walls are ICF block providing two continuous layers (R-23) of insulation around the slab, which will sit on an additional 4 inches (R-20) of low-VOC EPS foam.

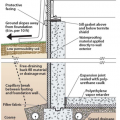

The goal of foundation moisture management is to construct the basement, crawlspace, or slab in a way that keeps moisture from getting in in the first place

The Habitat affiliate makes its own “ICF” foundation walls with rigid foam held in place with wood spacers.

The home’s slab-on-grade foundation is wrapped in a blanket of rigid foam extending completely under the slab and along the edges.

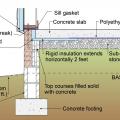

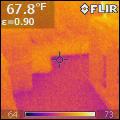

The seams of the rigid insulation are not taped and it will not provide a complete capillary break

There is polyethylene sheeting installed to provide a capillary break between the ground and slab

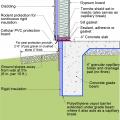

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This house with an insulated slab is protected from pests with a termite shield at the sill plate, borate-treated framing, insect screen covering bottom of furring air gap, and brick veneer over slab-edge insulation

This left-to-right sequence shows the method of wall extension to flood-proof a masonry house on a slab foundation. Here the new, raised floor is wood-framed over a wet-floodproofed crawlspace, but using fill to create a new raised slab is also an option.

This plumbing pipe is wrapped with a stainless steel mesh skirt that is clamped to the pipe before the concrete slab is poured to to keep out bugs and rodents

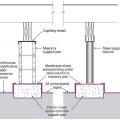

This raised-slab CMU and brick foundation includes flood-resistant features such as a sloped grade, capillary break under the slab (gravel or sand), vapor barrier under the slab (polyethylene sheet), and capillary break at the top of the foundation wall

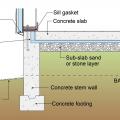

This raised-slab poured concrete foundation includes flood-resistant features such as a sloped grade, capillary break under the slab (gravel or sand), vapor retarder under the slab (rigid insulation), and capillary break at the top of the foundation wall

This Texas homes uses a slab foundation including a 4-in.-thick post-tensioned monolithic slab with turned-down edges poured over a 6-mil polyethylene vapor barrier and capillary break; slab edge insulation is not used due to termite risk.

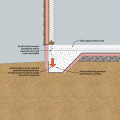

To help keep the monolithic slab-on-grade foundation dry, the site’s surfaces is graded away from the structure, the slab is poured on a bed of gravel, and using a vapor barrier will separate the foundation from the sill plates.

Two inches (R-10) of rigid foam line the interior of the perimeter footing walls before the post-tensioned slab is poured.

When adding an addition to an existing home, the new construction must meet current code.

Wrong - Polyethylene sheeting should be lapped up sides of walls and pillars and taped

Wrong – Drain pipe has been cut and foundation penetration has not been properly sealed

Wrong – No polyethylene sheeting vapor barrier is installed on the crawlspace floor

Wrong – Polyethylene sheeting does not completely cover the aggregate and the footing

Wrong – Polyethylene sheeting does not extend beyond edge of aggregate to separate the footer from the stem wall which will be poured next

Wrong – The footing drain pipe should end at least 10 feet from the foundation if above ground or should drain into a drywell or storm sewer.