Showing results 1 - 50 of 66

A sill-sealing foam gasket is placed under 8-inch plywood base and two beads of caulk air seal the 2x6 sill plate to it; two more beads of caulk will top the 2x6 which will serve as a spline for the SIP wall panel.

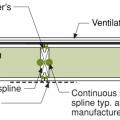

A structural spline made of a solid 2x is used where needed to meet structural load requirements at SIP panel seams

A surface spline reduces thermal bridging much more than a structural spline at SIP panel seams

All seams between structural insulated panels (SIPs) foamed and/or taped per manufacturer's instructions

Amerisips Homes LLC of South Carolina, built this traditional home on Johns Island, SC, and certified it to DOE Zero Energy Ready Home specifications in 2014.

An all-terrain forklift is used to move and stage the panels

An insulated spline is another option for avoiding thermal bridging at SIP panel seams

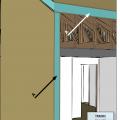

Because all of the structural load is carried by the SIP roof and wall panels, no trusses are needed, allowing the home to have vaulted ceilings and open interiors throughout.

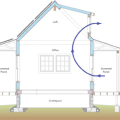

Building Science Corporation used convection to help cool this structural insulated panel (SIP) cottage in Georgia.

Carl Franklin Homes built this custom home in the cold climate in Garland, TX, and certified it to DOE Zero Energy Ready Home specifications in 2015.

Clifton View Homes built this custom for buyer home in the marine climate in Anacortes, WA, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Clifton View Homes built this custom for buyer home in the marine climate in Anacortes, WA, and certified it to DOE Zero Energy Ready Home specifications in 2017.

Clifton View Homes built this custom for buyer home in the marine climate in Anacortes, WA, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Clifton View Homes built this custom home in the marine climate in Coupeville, WA, and certified it to DOE Zero Energy Ready Home specifications in 2015.

Clifton View Homes built this custom home in the marine climate in Coupeville, WA, and certified it to DOE Zero Energy Ready Home specifications in 2014.

Clifton View Homes built this custom home in the marine climate in Port Hadlock, WA, and certified it to DOE Zero Energy Ready Home specifications in 2015.

Clifton View Homes built this system home in the marine climate in Whidbey Island, WA, and certified it to DOE Zero Energy Ready Home specifications in 2013.

Clifton View Homes employs a SIP precision construction system consisting of structural insulated panels that come to the site precut for quick assembly, providing a continuous thermal blanket around the home.

Construct exterior walls with structural insulated panels (SIPs) to provide an airtight wall with consistent insulation and very little thermal bridging.

Extra-wide air sealing tape seals seam where the structural insulated panels (SIPs) that form the roof and walls meet.

Ferrier Custom Homes built this custom for buyer home in the hot-humid climate in Fort Worth, TX, and certified it to DOE Zero Energy Ready Home specifications in 2017.

Ferrier Custom Homes built this custom for buyer home in the mixed-humid climate in Mineral Wells, TX, and certified it to DOE Zero Energy Ready Home specifications in 2019.

High Performance Homes built this custom for buyer home in the cold climate in Gettysburg, PA, and certified it to DOE Zero Energy Ready Home specifications in 2017.

High Performance Homes built this custom for buyer home in the mixed-humid climate in Easton, MD, and certified it to DOE Zero Energy Ready Home specifications in 2019.

High Performance Homes built this custom for buyer home in the mixed-humid climate in Westminster, MD, and certified it to DOE Zero Energy Ready Home specifications in 2018.

High Performance Homes built this production home in the cold climate in Gettysburg, PA, and certified it to DOE Zero Energy Ready Home specifications in 2015.

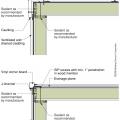

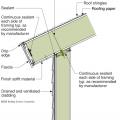

Install a housewrap drainage plane between the SIP panels and the exterior cladding

Insulated splines consisting of boards layered with rigid foam minimize energy loss at joints between the SIP wall panels.

Joints between SIP panels can be connected with solid lumber splines or SIP panel pieces. SIP panel pieces help to ensure a continuous layer of insulation across the building shell.

Lifting plates attached to the wall provide good bracing to tighten up SIP panel seams

Make sure the beads of caulk are continuous the full length at each SIP panel seam, such as at the wall-roof seam, to maintain air barrier continuity

Peel-and-stick panel tape provides added assurance that SIP panel seams will remain airtight

Peppertree Homes built this custom for buyer home in the cold climate in Waitsfield, VT, and certified it to DOE Zero Energy Ready Home specifications in 2016.

Right - Hole drilled to verify sealant is present - Hole will be sealed after verification

Right – A double bead of sealant seals the seams between the SIP panel and spline.

Right – A mall crew with a crane can assemble a home of structural insulated panels (SIPs) in just a few days.

Right – Graphite enhanced EPS fills these SIP panels, providing additional insulation value.

Right – SIP panels assemble quickly on site to provide sturdy walls and a roof that needs few interior supports so there is great flexibility in the layout of interior spaces.

Right – Structural insulated panels are quickly assembled on site for this SIP house.

Right – This home’s roof and walls are constructed of SIP panels; metal studs provide fastening surfaces across the long expanses of ceiling in the open interiors.

SIP homes built in coastal locations should be constructed so that the lowest level is well above the BFE.

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

SIP wall and roof panels can be sealed at all seams with a tenacious air sealing tape.

SIP walls do not require interior walls or trusses for support, providing for open interiors.