Showing results 1 - 19 of 19

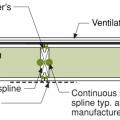

A structural spline made of a solid 2x is used where needed to meet structural load requirements at SIP panel seams

A surface spline reduces thermal bridging much more than a structural spline at SIP panel seams

An all-terrain forklift is used to move and stage the panels

An insulated spline is another option for avoiding thermal bridging at SIP panel seams

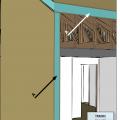

Construct exterior walls with structural insulated panels (SIPs) to provide an airtight wall with consistent insulation and very little thermal bridging.

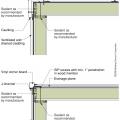

Install a housewrap drainage plane between the SIP panels and the exterior cladding

Lifting plates attached to the wall provide good bracing to tighten up SIP panel seams

Make sure the beads of caulk are continuous the full length at each SIP panel seam, such as at the wall-roof seam, to maintain air barrier continuity

Peel-and-stick panel tape provides added assurance that SIP panel seams will remain airtight

SIP panel walls are less susceptible to air leakage and convection issues than stick-built walls

SIP panels should be stacked high, dry, and flat

The back dam of the window sill will force water out

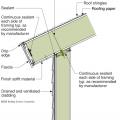

This foundation/floor/SIP wall detail shows recommended support of SIP wall panel at the sill plate

This technique for installing electrical wiring avoids the need to cut into the SIP panel

Two layers of high-permeability house wrap are installed to provide a drainage layer between the SIPS and the homes external cladding

Use a smoke pencil to check for air leaks at SIP panel seams, especially along the ridge beam

Walls are being assembled at this SIP house