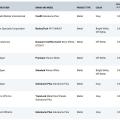

Showing results 451 - 500 of 578

The base of the plywood parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

The blocking for a new PV roof-mounting system is integrated with new rigid foam and the air and water control layers installed over an existing flat roof

The blocking is completely flashed with roofing membrane before the PV rack hardware is attached on a flat roof

The builder installed 1.5 inches of soy-based spray foam on the outside of the walls over the OSB sheathing, then kept a ¾ inch gap between the foam and the brick veneer siding to allow moisture vapor from the bricks to dissipate.

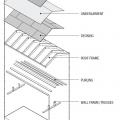

The components of a roof include the rafter framing or trusses, purlins, plywood roof decking, underlayment, and the roof covering.

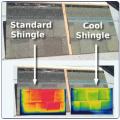

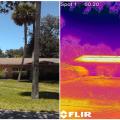

The cool shingles on the right have been coated with a ceramic coating to reflect near-infrared radiation, resulting in a cooler roof as shown by these thermal images (red and yellow are hotter, green and blue are cooler).

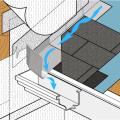

The diverter should be adequately sized to direct all of the water away from the wall and into the gutter.

The entire roof of the home is covered with an ice-and-water shield to help protect against moisture damage.

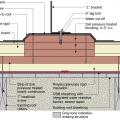

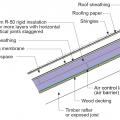

The existing 2x8 roof rafters were topped with OSB; two layers of 2-inch rigid foam; plywood; ice and water shield at rakes, eaves, and valleys; underlayment; and fiberglass shingles, plus 6 inches of open-cell foam under the decking.

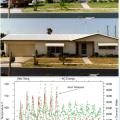

The existing dark tile roof on this home (top photo) was covered with a light -colored coating on day 6 (middle photo), resulting in a significant reduction in attic temperature and cooling energy consumption (bottom)

The existing flat roof before removal of membrane shows lack of slope allowing water to pool on the surface

The existing sheathing boards are removed near the perimeter of the flat roof and pressure-treated plywood is installed at the vertical face of the parapet

The geometry of this roof encouraged drifting of snow leading to heavy accumulation between the gables

The green framing is lumber that was pressure treated with borate to increase its resistance to termites, mold, and moisture

The icicles and the bare spot along the left roof ridge indicate that heat from the second-story room may be heating the underside of the roof deck, melting the snow and likely leading to ice dam formation.

The mechanical curb for a skylight is integrated with the water management and air control layers on a flat roof retrofitted to include new above-deck rigid foam insulation

The open-web roof and floor joists, laminated beams, and I-beams reduce raw lumber use and increase load-bearing capacity, while resisting shrinking, twisting, splitting, and warping.

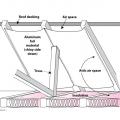

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The photovoltaic panels sit in a waterproof plastic tray that was installed directly on the roofing underlayment, then surrounded with roofing shingles.

The polyethylene ceiling vapor barrier is sealed to form an air barrier around the exhaust fan in this very cold climate location (≥ CZ 6).

The retrofitted flat roof has PV panels and walking mats installed over the roofing membrane

The roof trusses and all other framing in this hot-humid climate home is treated with borate for mold and termite resistance.

The simple gable roof is constructed at an unusual 6.55 pitch that allows exactly four and a half sheets of 4-foot- wide coated, taped roof sheathing to be installed as the roof deck with enough space at the peak for a continuous ridge vent.

The standard asphalt shingle roof on this Florida home readily absorbs solar energy, allowing it to heat up to 140°F (60°C) as shown in the thermal image on the right

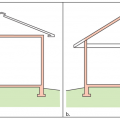

The thermal boundary for a gable roof can be located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

The varied roof pitches offer multiple options for solar panel placement regardless of home orientation for these production homes in Colorado.

The ventilation space in this vented over-roof keeps the roof cool to prevent ice dams over the unvented attic

The white TPO membrane roof on the row house on the right performs extremely well at reflecting solar energy and maintaining cool surface temperatures while the black EPDM membrane roof on the left heats up rapidly in the sunlight

The wood blocking for future PV panel installation extends above the surface of the top layer of polyisocyanurate rigid foam insulation installed as part of a flat roof retrofit

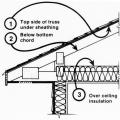

There are three potential locations for an attic radiant barrier – adhered to the underside of the roof decking, hanging from the rafters, or on the ceiling insulation

These snow guards help to keep snow from sliding off the roof and injuring people below.

This chimney was not adequately attached to the structure and fell away during an earthquake

This finished retrofit installation of radiant barrier in attic shows the air spaces at the soffit and ridge to promote attic ventilation

This home has heat loss through the roof, leading to ice dam formation and structural issues during winter months.

This home uses light-colored standard paints and finishes on siding and roofing materials to reduce cooling loads without adding material cost.

This home was designed with continuous roof vents and few roof penetrations, allowing more room for the solar shingles that integrate with the asphalt shingles installed to meet IBHS Fortified Roof criteria for increased resistance to high winds and rain

This home’s south-facing roof provides adequate space for both a solar electric system and solar thermal hot water system.

This house design in the Hot-Humid climate uses a slab foundation, masonry walls, and an Exterior Insulation Finish System (EIFS) cladding.

This roof is hurricane proofed with a coated insulated OSB deck sheathing that is caulked and taped at all seams with a water-resistant tape, then fully covered with a peel-and-stick membrane, and asphalt shingles.

This roof was constructed to meet the IBHS Fortified Roof standard by sealing the decking seams with flashing tape, installing synthetic roof underlayment secured with metal drip edge and nailed every six inches, and using self-adhered starter shingles.

This roof was insulated above the roof deck with 5.5 inches (R-38.5) of closed-cell spray foam.

This search for metal roofing products on the CRRC Rated Roof Products Directory highlights the initial and 3-year aged SRI values for each product

This simplified decision tree can help a homeowner or contractor assess how appropriate a cool roof or wall will be for a particular home

Three inches of closed-cell spray foam (R-19) and 7.5 inches (R-28) of open-cell spray foam was installed below the roof sheathing in this cathedral ceiling.

Three locations and methods for installing a roof deck radiant barrier in new construction

To keep water out, flashing should be integrated with the house wrap, siding, and shingles or roof tiles.

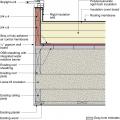

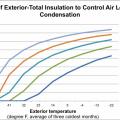

To reduce the risk of condensation on the interior of the roof sheathing in cold weather, the ratio of exterior (above-deck) insulation must be increased as a percent of total attic insulation as outside temperature decreases