Showing results 1 - 34 of 34

A gut rehab that includes drywall removal provides the opportunity to thoroughly insulate the walls.

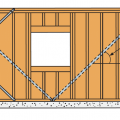

Add metal connectors to strengthen framing connections in an existing wall from inside the home by removing drywall.

Completed wall retrofit of masonry home (on right) showing new lap siding attached over four inches of rigid foam; windows were boxed with plywood to accommodate depth of foam plus 1x4 furring strips

Correct seismic retrofit hardware for securing the sill plate to foundation wall

Detail for reinforcing a cripple wall to resist earthquake movement by installing anchor bolts and plywood reinforcement.

Extension boxes of plywood built around the windows on this wall retrofit will be flush with the outer layer of exterior rigid insulation

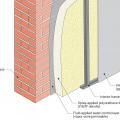

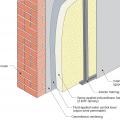

In this exterior wall retrofit of a masonry brick home, first the brick was covered with a fluid-applied water and air control layer (white), then 2x4 furring strips and two layers of rigid foam insulation, then 1x4 furring strips to attach cladding to

Incorrectly done seismic retrofit, the plywood sheathing is not nailed to the mud sill and therefore it is not providing any shear strength

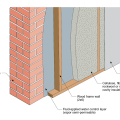

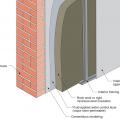

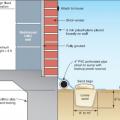

Masonry wall interior retrofit with fluid-applied water control layer and wood-framed wall with cavity insulation (climate zones 1-4 only)

Masonry wall interior retrofit with fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

Masonry wall interior retrofit with fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, mineral wool rigid foam, and wood or metal stud service cavity (climate zones 1-4 only)

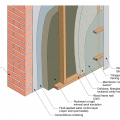

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, rigid mineral wool, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, spray foam, and wood or metal stud service cavity

Masonry wall interior retrofit with parge coat, fluid-applied water control layer, wood-framed wall with cavity insulation, smart vapor barrier, and wood or metal service cavity

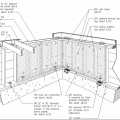

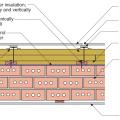

Plan view of exterior masonry brick wall retrofitted with furring strips, three layers of rigid mineral wool insulation staggered and taped at the seams, and topped with metal hat channel providing a ventilation gap surface to nail under the lap siding

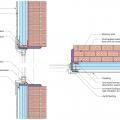

Side and plan views of window-to-wall interface in masonry wall retrofit including three layers of rigid foam exterior insulation, box extensions, and flashing around new windows.

Step 1. Remove the existing wall cladding to prepare to retrofit an exterior wall.

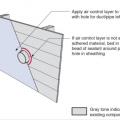

Step 2. Install a continuous air and water control layer over the existing wall sheathing.

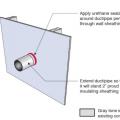

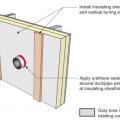

Step 3. Apply urethane sealant around the duct or pipe in the retrofitted exterior wall.

Step 4. Install insulating sheathing and vertical furring strips on the retrofitted exterior wall; seal around pipe or duct with urethane sealant.

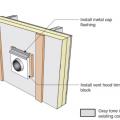

Step 5. Install sheathing tape flashing over the duct or pipe and wood blocking on either side for later attachment of trim.

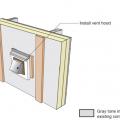

Step 6. Install vent hood trim block, metal cap flashing; seal top edge of flashing with sheathing tape.

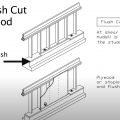

The flush cut method for seismic retrofit bracing of a cripple wall allows the plywood sheathing to be attached directly to both the cripple studs and the notched section of the mudsill

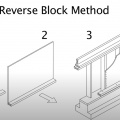

The reverse block method for seismic retrofit bracing of a cripple wall uses a 2x4 attached to the sill plate to provide a means to attach the plywood cripple wall sheathing to the sill plate

This close-up of an exterior wall retrofit of a masonry brick home shows the fluid-applied water and air control layer (white), 2x4 furring strips and two layers of rigid foam insulation (pink), then 1x4 furring which provides a ventilation gap

This simple decision tree can help homeowners and contractors make decisions about re-siding a home and upgrading windows

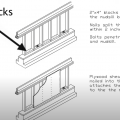

With the nailed block method, wood blocks are attached to the sill plate and the cripple wall plywood is attached to the block to provide shear strength for correctly bracing a cripple wall in a seismic retrofit