Showing results 101 - 128 of 128

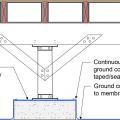

The polyethylene ground cover in the crawlspace is continuous at interior posts and piers

The recommended approach for groundwater management in cases where the foundation is entirely above the groundwater table.

The sheathing has rotted because there was not a sufficient drainage gap behind the stucco cladding

The top course of these concrete masonry unit (CMU) crawlspace foundation walls and piers is filled with grout then sprayed with a waterproofing membrane that acts as a capillary break and prevents moisture from migrating into the framing material.

This asphalt-based, vapor-permeable coating is painted directly onto the OSB sheathing to provide a weather-resistant barrier that also reduces air leakage.

This building foundation has a drainage layer located on the exterior of the waterproofing membrane.

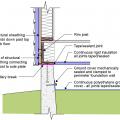

This farmhouse was retrofit by removing the existing siding and adding taped insulated sheathing and battens before installing new siding

This HRV, installed in a conditioned attic, provides balanced ventilation to the whole home

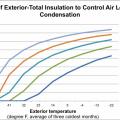

To reduce the risk of condensation on the interior of the roof sheathing in cold weather, the ratio of exterior (above-deck) insulation must be increased as a percent of total attic insulation as outside temperature decreases

Traditional methods of site drainage, such as site grading, can be difficult to achieve on urban sites.

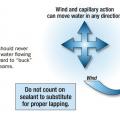

Weather barrier should be taped and sealed around all edges and penetrations to prevent moisture infiltration.

When architects and builders think of the house as a systems, all of the parts are designed to work together for a healthy, durable home that minimizes builder callbacks while cutting energy, maintenance, and repair costs down the road.

When condensation forms on the interior side of wall sheathing and is not able to dry out, it can lead to mold growth and rotting of wall sheathing and framing

When flood waters reach living areas, the resulting mold and contamination can greatly increase clean up time and costs.

When moisture is trapped inside walls, mold can grow unchecked, causing damage to the walls and health impacts for the occupants.

When rigid foam insulation is applied to the exterior side of the wall cavity under the cladding, with seams taped and an air gap provided, it acts as a vapor barrier, air barrier, and rain screen.

Wrong - Air leakage from the conditioned space to the basement foundation wall can lead to condensation or moisture issues in a conventional blanket insulation installation.

Wrong - Moisture from within the basement foundation wall can migrate into the insulation cavity in a conventional blanket insulation installation.

Wrong - Plastic-covered blanket insulation that is installed directly against concrete walls with no rigid foam or closed-cell spray foam covering the concrete could trap moisture coming through the concrete, leading to mold, moisture, and odor problems.

Wrong – A clothes dryer that vents to the crawlspace can contribute moisture to the crawlspace; this can result in damp, molding, and rotting insulation

Wrong – Don’t use nails to fasten poly vapor barrier around flex ducts; it will allow moist air to reach the ducts where it could condense and ruin the insulation.

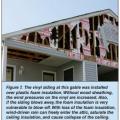

Wrong – The gable end wall failed because the rigid foam sheathing was not backed up by plywood or OSB.

Wrong: The fiber-cement siding has cracked due to over-driven nails located too close to the edge of the board; these cracks provide a pathway for bulk water entry and offer little resistance to high winds.

Wrong: The waterproofing around this hose bib was haphazardly detailed allowing water a pathway to wick behind the siding.