Showing results 451 - 500 of 898

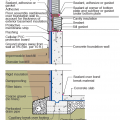

Right - This concrete basement wall has exterior rigid insulation and comprehensive moisture management details.

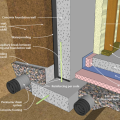

Right - This concrete basement wall is insulated on the interior basement walls with spray foam and under the slab with rigid foam; footing details are shown.

Right - This concrete basement wall is insulated on the interior with rigid insulation; sill details are shown.

Right - This concrete basement wall is insulated on the interior with spray foam insulation; sill detail are shown.

Right - This foil-faced polyisocyanurate rigid foam is installed on an existing exterior wall and the seams are taped so the rigid foam can serve as a water control layer

Right - This heated garage plenum is insulated along the bottom of the plenum space.

Right - This heated garage plenum is insulated and has an opening to access the interior, allowing for repairs and maintenance.

Right - This high-thermal-mass home uses masonry construction to naturally regulate temperatures inside the house

Right - This new sealed attic has 5.5 inches (R-20) of spray foam insulation along the underside of the roof deck providing a conditioned attic space for the heating and cooling ducts.

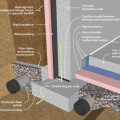

Right - This poured concrete basement wall is insulated on the exterior and under the slab with rigid insulation; footing details include interior and exterior footing drain pipe.

Right - This rigid insulation is correctly installed in a level layer over aggregate; the seams will be taped

Right - This unvented crawlspace is insulated along interior walls with rigid foam and air-sealed by covering the floor with vapor retarder that is sealed to the rigid foam which is taped at the seams.

Right - This unvented crawlspace is insulated along the walls and between the floor joists with 2-inch foil-faced polyisocyanurate; a termite inspection gap is visible above of the wall insulation and below the band joist.

Right - Workers installed rigid foam on the floor and the sill plates of these pre-cast, pre-insulated concrete wall panels to provide a continuous layer of insulation under and around the not-yet-poured basement floor slab.

Right - XPS foam insulation is attached to the existing exterior wall with wood furring strips that serve as a nail base for the siding and are installed vertically to allow for drainage and drying behind the siding

Right - XPS rigid foam board is tightly installed against a concrete foundation wall and seams are sealed with tape prior to installing fibrous blanket insulation.

Right – Attic access hatch has been properly insulated by attaching a fiberglass batt, gasketed, and opening has blocking

Right – 11-inch ICFs provide R-50 of wall insulation from the footing to the roof on this cold-climate home.

Right – A 1-inch layer of XPS rigid foam covers the 2x6 wall studs and is topped by ½-inch-thick plywood sheathing, which is covered with draining house wrap and serves as a nailing surface for siding and trim.

Right – A termite inspection gap is left at the top of the rigid foam board basement wall insulation.

Right – After installing the insulated concrete foundation wall panels, the builder installed underslab rigid foam, which was topped by 4 inches of crushed rock then the poured slab.

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

Right – All supply ducts in this home were located in conditioned space; any return ducts that were located in the attic were insulated with closed-cell spray foam and buried in the blown-in attic insulation to prevent air leakage and heat loss.

Right – an instructor shows a student how to cut batt insulation around wiring rather than compressing the batt behind the wiring.

Right – An insulated space is provided in the home’s attic to house the HVAC equipment.

Right – Attic access door has foam and rubber weatherstripping installed that remains in contact when closed.

Right – Batt insulation provides additional insulation for the home’s main duct chase.

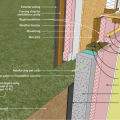

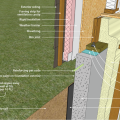

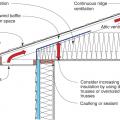

Right – Battens were installed above the cork insulation to provide a ventilating layer between the insulation and the roof sheathing on this “hot roof” design.

Right – Blocking has been installed around the perimeter of this attic access to prevent insulation falling into the house

Right – Closed-cell polyurethane foam is sprayed on the underside of the roof deck to provide structural connections and seal seams in the sheathing to increase wind resistance

Right – Construction adhesive is applied to the rigid foam panels that will be installed on the interior basement walls.

Right – Even house wrap is installed in the factory for these modular homes where each floor is factory assembled.

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Furring strips provide a drainage and ventilation gap between the siding and the cork insulation.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Furring strips were installed to provide a 3/8-inch drainage plane over the rigid foam and under the fiber cement lap siding.

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – Insulated concrete forms (ICFs) provide the insulated stem wall for the slab-on-grade foundation for this SIP house.

Right – Insulation installed to correct depth and will be aligned with air barrier