Showing results 701 - 750 of 898

The home is sheathed with rigid foam insulation and all seams and holes are taped to provide a continuous air barrier.

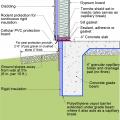

The home’s slab-on-grade foundation is wrapped in a blanket of rigid foam extending completely under the slab and along the edges.

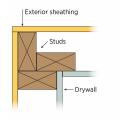

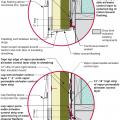

The improved three-stud corner allows insulation to be installed later, in sequence

The inner liner of the flex duct is fastened to the collar with a tension tie, the connection is sealed with mastic, then the outer layer is pulled over and sealed with mastic or foil tape (Steven Winter Associates 2013).

The Larsen-truss 9-inch wall cavities were covered with a smart vapor membrane that was fastened to the trusses with furring strips, which also provide an air gap behind the wood siding; each truss cavity is then filled with blown cellulose.

The main trunk line of the ducts runs within an insulated duct chase installed in a notch designed into the roof trusses that runs the length of the home to provide supply air directly to most of the home’s ceiling registers.

The missing top plate in a kneewall was covered with lumber and rigid foam insulation and then sealed with spray foam

The original corner seam is air-sealed with caulk, then rigid foam is installed on the existing garage ceiling and walls, and finally covered with drywall.

The OSB roof decking product comes with an adhered radiant foil barrier which helps to prevent heat transfer in or out of the vented attic, while R-13 unfaced fiberglass fills the advanced-framed 2x6 walls.

The retrofitted flat roof has PV panels and walking mats installed over the roofing membrane

The rim band connecting the insulated precast concrete basement walls to the floor joists above is spray foamed to provide air-sealing and insulation in this hard-to-seal juncture.

The rim joists and top plates are air sealed and insulated with open-cell spray foam while the walls are filled with blown fiberglass.

The sealed, insulated crawlspace is a clean, dry location to house the main floor heating ducts and also provides bonus storage space.

The seams in the ceiling drywall are sealed from the attic side with spray foam.

The soffit dam and baffle allow air to flow through the vents without disturbing the insulation covering the top plates

The spray foam-insulated attic provides a temperate place for the ERV ducts, which provide filtered fresh air to every room in the house.

The tape is covered with mastic to ensure an airtight seal between the duct and the fitting

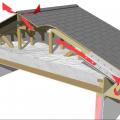

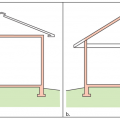

The thermal boundary for a gable roof can be located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

The unvented attic is insulated along the underside of the roof deck with 7 inches (R-49) of closed-cell spray foam, providing vaulted ceilings and a conditioned knee wall space for ducting.

The use of blown-in fiberglass insulation allows the double wall cavity to be filled in completely with no voids that could create cold spots in the walls.

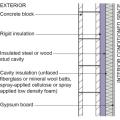

The wall’s concrete blocks are filled with foam and covered with an interior continuous thermal blanket of rigid foam insulation.

The walls and ceilings of this post-and-beam home are filled with netted blown fiberglass.

The wood blocking for future PV panel installation extends above the surface of the top layer of polyisocyanurate rigid foam insulation installed as part of a flat roof retrofit

Thermally isolate heated garages in multifamily buildings from ambient space, and thermally isolate all garages in multifamily buildings from interior occupied space. This parking garage is thermally isolated from space above with spray foam insulation.

These below-grade walls are insulated along the exterior with R-5 of bug-resistant high-density rigid fiberglass insulation installed over damproofing.

These factory-built walls consist of 9.5-inch I-studs sheathed with coated OSB, faced with OSB, and dense-packed with cellulose; a second interior surface of drywall is added to provide a 1.5-inch cavity for electrical wiring.

This 2x6 wall is advanced framed and filled with dense-packed cellulose insulation.

This 4-inch layer of rigid foam insulation (R-20) will be sandwiched between two layers of concrete poured on site for a highly insulated foundation wall.

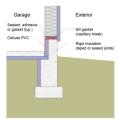

This assembly can be used to thermally isolate heated or partially heated garages with slab foundations from the exterior in multifamily row houses/townhouses in IECC Climate Zones 3 and higher.

This assembly for above-grade and below-grade garage walls in any climate zone uses continuous rigid insulation along the interior of the wall.

This assembly for above-grade or below-grade garage walls in any climate zone uses a hybrid of continuous rigid insulation and cavity insulation on the interior side of the wall.

This attic is insulated to R-64 with a hybrid application of 11 inches of open-cell spray foam (R-4.45/in) plus 2 inches of closed-cell spray foam (R-7.4/in) that completely fills the roof rafter cavities and encases the rafters.

This attic was insulated with 5 inches of closed-cell spray foam on the underside of the roof deck plus 6.5 inches of blown fiberglass covered with sheetrock as a firebreak for a total R-58 roof assembly insulation value.

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This builder applied an air-sealing layer of spray foam along the underside of the roof deck and the inside of the walls before filling the wall cavities with blown cellulose.

This builder installs spray foam in exterior wall cavities where tubs and showers will be installed to air seal and insulate the exterior wall.

This close-up of an exterior wall retrofit of a masonry brick home shows the fluid-applied water and air control layer (white), 2x4 furring strips and two layers of rigid foam insulation (pink), then 1x4 furring which provides a ventilation gap

This community of production homes in central New York state was built with insulated concrete forms (ICFs), which provide a highly insulated, airtight structure that is fire-, pest-, wind-, and earthquake-resistant.

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

This fiberglass batt insulation has a kraft paper facing that is correctly stapled to the face rather than the sides of the wall studs to minimize compression.

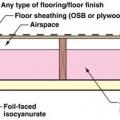

This floor assembly above a vented crawlspace controls vapor and heat transmission by using foil-faced isocyanurate rigid foam insulation installed underneath the floor joists and fiberglass insulation in the floor joist cavities

This Habitat for Humanity builder ordered roof trusses with a 2-foot by 2-foot notch next to the center post then lined the cutout with rigid foam to form an insulated central duct chase to bring the heating and cooling ducts within the conditioned space.

This heated garage plenum is insulated along the bottom and sides, and the insulation is fully aligned with an air barrier. The insulation at the bottom of the plenum space meets IECC insulation requirements.

This heated garage plenum space is insulated along its top, bottom and sides, and the insulation at the top of the plenum meets IECC requirements. The insulation along the top and sides is fully aligned with an air barrier.

This home has a cost-saving shallow frost-protected foundation that uses rigid foam laid vertically at the base of the 16-inch-deep footers to protect the foundation from frost damage.