Showing results 651 - 700 of 898

Spray foam insulation is installed in open wall cavities to air seal and insulate

Spray foam insulation used for raised ceiling duct chase

Spray foam insulation was installed on the underside of the roof deck and on gable end attic walls to create an unvented attic

Spray foam is installed between new studs over the existing siding in this deep energy retrofit

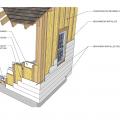

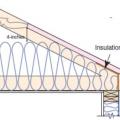

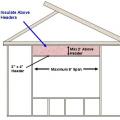

Standard roof trusses are narrow at the eaves, preventing full insulation coverage over the top plate of the exterior walls

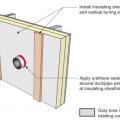

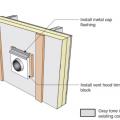

Step 4. Install insulating sheathing and vertical furring strips on the retrofitted exterior wall; seal around pipe or duct with urethane sealant.

Step 5. Install sheathing tape flashing over the duct or pipe and wood blocking on either side for later attachment of trim.

Step 6. Install vent hood trim block, metal cap flashing; seal top edge of flashing with sheathing tape.

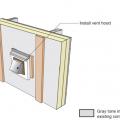

Step 8. Attach the new cladding to the furring strips over the rigid foam for the exterior wall retrofit.

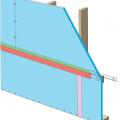

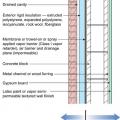

Stucco is installed over rigid insulation, which is installed over a drainage plane consisting of a drainage gap and building wrap layer over the sheathing

Stuff cavities under kneewalls with rolls of fiberglass batt and spray foam in place

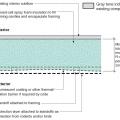

Tape horizontal joint with minimum 3" wide tape placing tape offset high on the joint, adhearing to the upper sheet without wrinkles

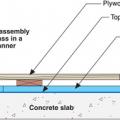

Taped plywood creates a continuous sheathing layer while cork adds a layer of continuous insulation to the outside of the wall.

Terminate 4" tape with 2" wide tape placing tape offset high on the joint, 2/3 of the tape should be adhered to the sheet of insulation

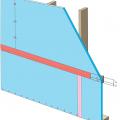

The “institutional” perfect wall works in all climate zones; water, air, vapor, and thermal control layers are exterior of the sheathing, assembly allows drying to interior and exterior

The advance-framed 2x6 24-inch on-center walls are covered with netting then filled with R-23 blown fiberglass.

The application of intumescent coating/protection layer protects this elevated floor system from below.

The attic duct chase insulated and sealed to the attic floor with spray foam

The attic is insulated along the underside of the roof deck with 8 inches of open-cell spray foam.

The attic is sealed and insulated along the underside of the roof deck with 5.5 inches of polyurethane spray foam, providing conditioned space for the HVAC system.

The attic knee walls were constructed from 2x6s and insulated with R-19 batt, backed with 1 inch of XPS foam board with taped joints to provide a solid air barrier over the insulated surfaces.

The attic kneewall and the open floor cavities under kneewall are both sealed and insulated in one step with spray foam insulation

The base of the plywood parapet is air sealed with spray foam and fibrous insulation is installed in the rafter cavities in this flat roof retrofit

The basement is constructed with precast concrete walls lined with R-21.3 foil-faced rigid foam while an R-10 layer of XPS rigid foam covers the ground under the slab.

The basement slab is wrapped in a blanket of insulation including R-27 of closed-cell spray foam under the slab and R-22 ICF blocks wrapping the slab edges.

The basement walls’ interior framing is set in 3 inches from the concrete to allow space for closed-cell foam that is sprayed directly on the concrete, then blown cellulose is added to fill the wall cavity.

The batt insulation shown here was properly installed to fill the ceiling cavities.

The builder in this very cold climate installed three layers of unfaced mineral wool batt in the double wall with a code-required vapor barrier between the middle and inner layers of wall insulation that is taped to barriers in the ceiling and floor.

The builder installed 1.5 inches of soy-based spray foam on the outside of the walls over the OSB sheathing, then kept a ¾ inch gap between the foam and the brick veneer siding to allow moisture vapor from the bricks to dissipate.

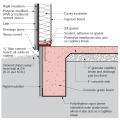

The builder laid down a 4-inch base of aggregate rock, then covered that with a plastic vapor barrier that is taped at all seams and around all penetrations before installing the rigid foam under-slab insulation.

The builder was able to pack R-41 of blown fiberglass into the wall cavity formed by the double stud walls.

The builder’s crews spray foam directly onto the ground to provide a vapor barrier and insulation layer under the slab.

The builders sprayed the underside of the roof assembly with 6 inches of open-cell spray foam to create an unvented, R-48 insulated attic.

The ceiling over an unconditioned space is insulated with closed-cell spray foam that fills the ceiling cavities and encapsulates the framing

The daylight basement walls are made of concrete walls with integrated rigid foam and steel-faced concrete studs.

The double walls form a 12-inch cavity that was sheathed with a coated OSB then coated with 3 inches of closed-cell spray foam; they will be filled with 9 inches of blown fiberglass.

The energy-saving double wall construction uses two side-by-side stud walls, providing an extra-thick wall cavity that can be filled with more than twice as much insulation as a 2x6 wall.

The enhanced comfort attic insulation consists of an ultra-efficient 25-inch-thick layer of blown cellulose providing a substantial R-90 insulation value.

The existing 2x8 roof rafters were topped with OSB; two layers of 2-inch rigid foam; plywood; ice and water shield at rakes, eaves, and valleys; underlayment; and fiberglass shingles, plus 6 inches of open-cell foam under the decking.

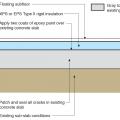

The existing slab is retrofitted by coating with epoxy paint, then installing rigid foam insulation and a floating subfloor.

The existing slab is retrofitted with epoxy paint, rigid foam insulation, sleepers (furring strips), and subfloor.

The exterior of the home is wrapped in a continuous layer of rigid foam with all seams taped to provide a thermal, air, and moisture barrier and serve as a drainage plane, eliminating the need for house wrap.

The exterior walls of this home consist of two wall cavities: a 2x6 wall with plywood sheathing plus 8-inch I-joists sheathed with engineered wood; both cavities are dense-packed with cellulose for R-60 total.

The floor slab is completely insulated with ICF foundation walls and R-20 (3 inches) of closed-cell foam that is sprayed directly onto the ground before pouring the slab.

The foam-filled concrete block walls are lined on the interior side with foil-faced rigid foam then topped with furring strips for attaching drywall.

The foil-faced insulation behind this fireplace provides an air barrier and thermal shield.

The foundation walls are ICF block providing two continuous layers (R-23) of insulation around the slab, which will sit on an additional 4 inches (R-20) of low-VOC EPS foam.