Showing results 501 - 550 of 898

Right – Joists between floors are air sealed to the ceiling drywall with canned spray foam along each joist-to-drywall-seam.

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

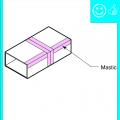

Right – Metal or fiberboard duct is mastic sealed at junction with duct register box

Right – Mineral wool batt insulation is cut to fit snuggly and to fully fill wall cavities with minimal voids and gaps.

Right – Netted blown fiberglass insulation completely fills the wall cavities with no gaps or voids.

Right – Open-cell spray foam is installed over closed-cell spray foam in this hybrid approach to achieve adequate attic ventilation while allowing some vapor permeability.

Right – Plastic tenting increases the height of the insulation above ducts that are located in the attic.

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Precast concrete basement walls come to the site with integrated insulation and steel-faced concrete studs.

Right – Prepoured foundation panels with integrated insulation and vapor barrier are installed in place.

Right – R-20 of XPS and polyiso rigid foam were added on the slab shelf that is part of this precast foundation wall system.

Right – R-23 of blown fiberglass fills the walls and unvented vaulted attic cavities of this marine-climate home while an additional R-20 (4-inches) of graphite-enhanced expanded polystyrene is installed above the roof sheathing.

Right – R-25 of open-cell spray foam lines this new home’s attic ceiling, to protect HVAC ducts from heat and cold.

Right – Raised heel trusses allow for full-height insulation over exterior wall top plates.

Right – Rigid foam is installed behind HVAC ducts to provide additional insulation to the ducts which are installed within the conditioned space.

Right – Rigid foam was attached to the tops of the precast foundation walls to form an insulated edge for the floor slab.

Right – Ripped OSB provides furring strips for a ventilation gap behind the wood siding.

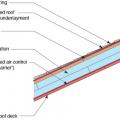

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

Right – Roof underlayment is fully adhered and roof deck seams are sealed so roof is resistant to high-wind events

Right – Spray foam air seals and insulates the walls including the walls behind the fireplace and covers the underside of the roof deck of this mixed-dry climate home to provide an insulated attic space for HVAC ducts.

Right – Spray foam completely fills the wall cavities, providing a thorough layer of insulation behind electrical boxes.

Right – Spray foam fills the roof joist cavities of this vaulted, unvented attic.

Right – Spray foam insulates the walls and ceilings separating the garage from the home.

Right – Spray foam insulation fills the header above the door and fills the rim joist between floors.

Right – Spray foam insulation is sprayed on the underside of the roof deck to provide a conditioned space in this low attic for the HVAC ducts.

Right – Spray foam insulation was sprayed onto the ground and along the sides of the foundation walls and piers of this insulated crawl space.

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – Terra cotta tiles are attached to horizontal metal furring strips as the exterior cladding over mineral wool insulation on this multi-family building in Colorado.

Right – the 2x6 walls are insulated with a flash-and-batt approach that includes spraying the wall cavities with one inch of open-cell foam to seal the sheathing to the framing then filling the wall cavities with R-19 fiberglass batts that are compressed

Right – The air- and water-barrier material lining the shower stall is mastic sealed to prevent leakage and rigid foam insulation is installed on the floor of the shower.