Showing results 801 - 898 of 898

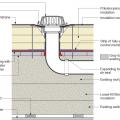

Water management details for a roof drain installed along with rigid foam on a flat roof

When architects and builders think of the house as a systems, all of the parts are designed to work together for a healthy, durable home that minimizes builder callbacks while cutting energy, maintenance, and repair costs down the road.

When condensation forms on the interior side of wall sheathing and is not able to dry out, it can lead to mold growth and rotting of wall sheathing and framing

When wrapping metal ducts with insulation allow two inches of overlap and staple along the seam with outward clinching staples

Windows are installed as “outies” in this wall assembly using a self-adhered membrane water and air control layer with continuous exterior insulation

Windows are installed in new framing in preparation for adding exterior spray foam insulation

Wiring runs are covered with canned spray foam to maintain the continuous foam layer that covers the inside and outside of these ICF block walls.

Wood blocking for future PV panel installation is installed in the layers of polyisocyanurate rigid foam insulation during a flat roof retrofit

Wrap batt insulation around pipe loosely enough not to compress the insulation and secure with wire or tape

Wrong - Air leakage from the conditioned space to the basement foundation wall can lead to condensation or moisture issues in a conventional blanket insulation installation.

Wrong - Batt insulation does not provide complete coverage across the attic floor so ceiling joists are exposed resulting in thermal bridging.

Wrong - Ceiling insulation is not completely installed and air barrier is missing.

Wrong - Cold spots along the top plate combined with lack of ventilation have encouraged mold growth along this bathroom ceiling.

Wrong - Continuous rigid insulation was not installed to continuously cover the sheathing.

Wrong - Craft faced batt insulation is compressed behind PEX pipe instead of being sliced to fit around it.

Wrong - Craft faced batt insulation is not cut to fit around wiring and eletrical boxes and is squished into corners forming voids which could encourage cold spots in wall.

Wrong - Dark pattern on wall is showing where warm air is leaking into the wall cavity from interior of home.

Wrong - Dark patterns on the Home's exterior siding show where warm air is leaking into the wall cavities.

Wrong - Foil air barrier was ripped to install wiring; foil should be replaced with a solid air barrier and wiring hole should be caulked.

Wrong - Insulation beneath window is compressed and there are more support studs than necessary to left of window.

Wrong - Lack of insulation in the wall above this window combined with poor bathroom ventilation has contributed to mold growth.

Wrong - Moisture from within the basement foundation wall can migrate into the insulation cavity in a conventional blanket insulation installation.

Wrong - Plastic-covered blanket insulation that is installed directly against concrete walls with no rigid foam or closed-cell spray foam covering the concrete could trap moisture coming through the concrete, leading to mold, moisture, and odor problems.

Wrong - Polyethylene sheeting should be lapped up sides of walls and pillars and taped

Wrong - The basement blanket insulation is loosely attached to the interior of the basement wall, does not cover the entire wall, is not sealed at the edges, and is not installed over rigid foam that covers the entire surface of the foundation walls.

Wrong - The fiberglass blanket insulation has no perforated vapor retarder, does not cover the entire basement wall, is not sealed at the edges, and is not installed over rigid foam.

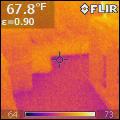

Wrong - The roof insulation panels for this building were not installed in multiple layers with joints offset. The snow melt pattern shows thermal bypasses at the insulation panel joints.

Wrong - This plastic-covered blanket insulation is not perforated, does not cover the entire basement wall, is not sealed at the edges, and is not installed over rigid foam.

Wrong - Unfaced fiberglass batt is not properly cut to fit in all the stud bays.

Wrong - Wall cavities behind shower are not completely filled with insulation and are lacking the solid interior air barrier.

Wrong – A clothes dryer that vents to the crawlspace can contribute moisture to the crawlspace; this can result in damp, molding, and rotting insulation

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – Compression and misalignment because insulation is not split around plumbing

Wrong – Compression and misalignment because insulation is not split around wires

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen

Wrong – Design walls so that windows are positioned to fit regularly spaced studs so less additional studs are needed.

Wrong – Don’t use nails to fasten poly vapor barrier around flex ducts; it will allow moist air to reach the ducts where it could condense and ruin the insulation.

Wrong – Either this tape was not pressed down firmly or the surface was wet or dirty so the tape is not sticking properly even during construction.

Wrong – If the insulated sheathing will serve as an air barrier and drainage plane, any cuts and seams must be taped or sealed.

Wrong – No blocking installed to prevent attic insulation from falling into stairs and opening

Wrong – Roof underlayment is not fully adhered and roof deck seams are not sealed so roof is susceptible to high-wind events

Wrong – The backing on this knee wall was not air sealed prior to adding insulation.

Wrong – The batt insulation on this knee wall is not properly supported and there is no air sealed rigid backing to provide a solid air barrier.

Wrong – The framing and wind baffle installation will not allow for required insulation depth.

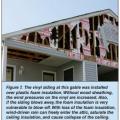

Wrong – The gable end wall failed because the rigid foam sheathing was not backed up by plywood or OSB.

Wrong – The polyethylene sheeting vapor barrier is not attached to the piers with mechanical fasteners

Wrong – When insulated sheathing is installed correctly, you should not see daylight. Nail holes were also left unplugged.

Wrong – When insulating with spray foam, care should be taken to completely fill areas around piping and other penetrations to avoid leaving air gaps.

Wrong – When more than one layer of insulation is installed, the seams should be staggered to discourage ground water from reaching the foundation wall.

Wrong- A tie strap should not be used over the duct outer liner because it can compress the insulation. Tuck in the fibrous insulation and seal the outer liner to the connecting duct with mastic or foil tape (Steven Winter Associates 2013).

Wrong: Closed-cell spray foam roof insulation was not thick enough to meet IRC levels so the foam surface is colder than the dew point of the interior air and condensation formed on surface of the foam

Wrong: Ducts are held above the ceiling plane with strapping to provide a good angle into top-entry boots. Once the ceiling insulation is added, this duct will protrude from the ceiling insulation and will not be buried

Wrong: Ducts are held from the rafters with strapping and a large beam prevents ducts from properly lying on the ceiling plane

Wrong: Ducts are not laid across the lower truss cords or ceiling, but are hung from the rafters by straps. As a result, ductwork is not buried

Wrong: Ductwork is not fully encapsulated with ccSPF insulation. The duct jacket is still fully visible at sections of the duct

Wrong: This exhaust fan duct is too long and terminates in the attic instead of going through the roof and it is improperly supported; it needs straps all along its length to prevent sagging.