Showing results 351 - 400 of 415

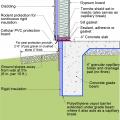

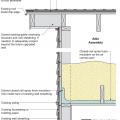

This basement is insulated on the exterior with rigid foam over dampproofing, with granular backfill and footing drains to facilitate drainage away from the foundation, a termite shield to protect from pests, and cellular PVC to protect the rigid foam.

This close-up of an exterior wall retrofit of a masonry brick home shows the fluid-applied water and air control layer (white), 2x4 furring strips and two layers of rigid foam insulation (pink), then 1x4 furring which provides a ventilation gap

This community of production homes in central New York state was built with insulated concrete forms (ICFs), which provide a highly insulated, airtight structure that is fire-, pest-, wind-, and earthquake-resistant.

This exterior insulated slab-on-grade monolithic grade beam foundation is protected from pests by termite shield at the sill plate, borate-treated framing, flashing at end of wall insulation, brick veneer over slab-edge insulation, and rock ground cover.

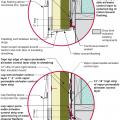

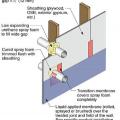

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated irregular foundation wall

This fiberglass batt insulation has a kraft paper facing that is correctly stapled to the face rather than the sides of the wall studs to minimize compression.

This home has heat loss through the roof, leading to ice dam formation and structural issues during winter months.

This home’s 2x6 advanced framed walls are insulated and air sealed with 3 inches of closed-cell spray foam.

This home’s exterior walls consist of two 2x4 walls; the R-49 double wall cavity is filled with 2 inches of closed-cell spray foam plus dense-packed cellulose.

This home’s exterior walls include Larsen trusses, 9-inch I-joists attached through exterior sheathing to wall studs creating a 9-inch wall cavity that was filled with blown insulation and forms extra deep windowsills.

This hot climate zone home uses high quality batt insulation between studs to insulate this connecting garage wall.

This hot climate zone home uses high quality batt insulation to insulate truss-joist headers.

This kneewall has no top plate and the resulting gap provides a wide-open pathway for air and vapor to travel between the living space and the attic

This unfaced fiberglass completely fills the wall cavities, with RESNET Grade 1 insulation.

To ensure a complete air barrier between the garage and the house, the wall between the garage and the house was insulated and air-sealed with four inches of high-density spray foam.

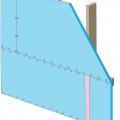

Two layers of XPS are installed with staggered seams over a liquid-applied membrane on the structural sheathing

Unfaced batt and blown fiberglass wall insulation are installed to RESENET Grade 1 standards with no gaps or voids.

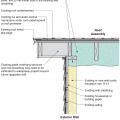

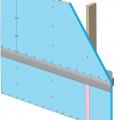

Unvented roof assembly at eave retrofitted with rigid foam, spray foam, and taped top edge of existing house wrap or building paper

Unvented roof assembly at rake retrofitted with spray foam installed along the underside of the roof deck and extended to the rake edge to insulate and air seal the attic

Use flashing tape to seal around any pipes or vents that penetrate through the foam

Vapor-permeable mineral wool insulation is installed on the exterior side of the sill beam during an exterior wall retrofit to allow the sill beam to dry to the outside

Vented roof assembly at eave retrofitted with rigid foam, spray foam, and fully adhered membrane to air seal the top of wall-to-roof transition

Vented roof assembly at rake retrofitted with spray foam and additional insulation installed at the attic floor and extended to the rake edge

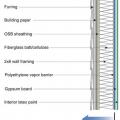

Walls in cold climates with a Class 3 vapor retarder (latex paint) and a vapor-open continuous insulation like mineral wool allow drying to the interior or the exterior

Walls in cold climates with a polyethylene vapor barrier interior of the wall cavity should have either no exterior insulation or a vapor-open continuous insulation like mineral wool that allows drying to the exterior

Windows are installed in new framing in preparation for adding exterior spray foam insulation

Wiring runs are covered with canned spray foam to maintain the continuous foam layer that covers the inside and outside of these ICF block walls.

Wrong - Continuous rigid insulation was not installed to continuously cover the sheathing.

Wrong - Craft faced batt insulation is not cut to fit around wiring and eletrical boxes and is squished into corners forming voids which could encourage cold spots in wall.

Wrong - Dark pattern on wall is showing where warm air is leaking into the wall cavity from interior of home.

Wrong - Dark patterns on the Home's exterior siding show where warm air is leaking into the wall cavities.

Wrong - Unfaced fiberglass batt is not properly cut to fit in all the stud bays.

Wrong - Wall cavities behind shower are not completely filled with insulation and are lacking the solid interior air barrier.

Wrong – A visible gap in the insulated sheathing introduces unwanted outside air, creating a thermal bypass and encouraging convective air flow

Wrong – Conventional T-post detail is extremely difficult to insulate and usually doesn't happen