Showing results 251 - 300 of 415

Right - The poured concrete basement walls are insulated along the inside with 2.5 inches of extruded polystyrene insulation.

Right - The slab-on-grade foundation is insulated with two layers (R-20) of XPS foam under the-slab and R-10 on the exterior of the stem walls.

Right - These attic knee walls are insulated with rigid foam and sealed with spray foam to form a continuous air barrier at the gable end of this cathedral ceiling.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

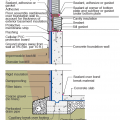

Right - This concrete basement wall has exterior rigid insulation and comprehensive moisture management details.

Right - This foil-faced polyisocyanurate rigid foam is installed on an existing exterior wall and the seams are taped so the rigid foam can serve as a water control layer

Right - This high-thermal-mass home uses masonry construction to naturally regulate temperatures inside the house

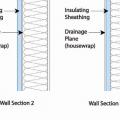

Right - XPS foam insulation is attached to the existing exterior wall with wood furring strips that serve as a nail base for the siding and are installed vertically to allow for drainage and drying behind the siding

Right – All insulated sheathing boards are installed according to the manufacturer’s recommended fastening schedule and taping specifications

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – Ladder blocking allows the exterior wall to be insulated where intersected by an interior wall.

Right – Mineral wool batt insulation is cut to fit snuggly and to fully fill wall cavities with minimal voids and gaps.

Right – Netted blown fiberglass insulation completely fills the wall cavities with no gaps or voids.

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right – Raised heel trusses allow for full-height insulation over exterior wall top plates.

Right – Spray foam completely fills the wall cavities, providing a thorough layer of insulation behind electrical boxes.

Right – Spray foam insulates the walls and ceilings separating the garage from the home.

Right – Structural insulated sheathing can provide racking strength (lateral load resistance), and serve as an air barrier and thermal barrier if installed according to manufacturer’s specifications with taped, sealed seams

Right – Terra cotta tiles are attached to horizontal metal furring strips as the exterior cladding over mineral wool insulation on this multi-family building in Colorado.

Right – the 2x6 walls are insulated with a flash-and-batt approach that includes spraying the wall cavities with one inch of open-cell foam to seal the sheathing to the framing then filling the wall cavities with R-19 fiberglass batts that are compressed

Right – The builder constructed a mock up of the wall assembly for this multi-family building.

Right – The exterior wall cavities are completely filled with dense-packed cellulose.

Right – The window header is filled with spray foam and sealant is used to air seal wood-to-wood seams; however, it would be preferable to design the wall to avoid so many stacked studs around the windows because they prevent wall insulation installation.

Right – This attic knee wall and the floor joist cavity openings beneath it are being sealed and insulated with spray foam.

Right – This foil-faced foam sheathing has taped seams and proper flashing details so it can serve as a drainage plane.

Right – This home is framed with double walls – two 2x4 walls set next to each other then sheathed with OSB on the exterior and netted on the interior face to create an extra-deep wall cavity that can be filled with blown-in insulation.

Right-- IR photo shows how effectively spray foam insulated/air sealed attic kneewall and the floor cavities under kneewall

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

Rigid foam insulated sheathing placed exterior to house wrap, interior to house wrap, or take the place of the house wrap