Showing results 101 - 150 of 415

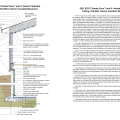

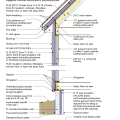

2021 IECC Climate Zone 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement (with notes)

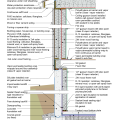

2021 IECC Climate Zones 7 and 8: Vented Attic, 2x4 Wall, Interior Insulated Basement

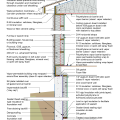

2021 IECC Climate Zones 7 and 8: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zones 7 and 8: Vented Attic, ICF Wall, ICF Basement Foundation

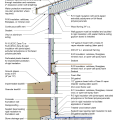

2021 IECC Climate Zones 7 and 8: Vented Attic, Interior Double Wall, Interior Insulated Basement

2021 IECC Climate Zones 7 and 8: Vented Attic, Strapped 2x6, Interior Insulated Basement

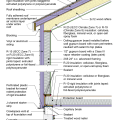

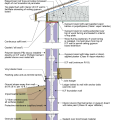

2021 IECC Climate Zones 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

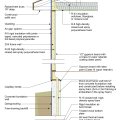

2021 IECC Climate Zones 7 and 8: Vented Cathedral Ceiling, 2x6 Wall, Slab on Grade

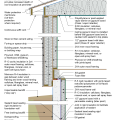

2021 IECC Climate Zones 7 and 8: Vented Over-Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

A builder, energy efficiency consultant, and crew supervisor inspect a spray foam installation.

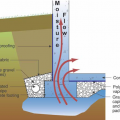

A continuous layer of polyethylene covers the crawlspace floor and is attached to the wall with wood nailing strips

A gut rehab that includes drywall removal provides the opportunity to thoroughly insulate the walls.

A typical Las Vegas hot-dry climate home made of wood frame construction and insulated with R-25 expanded polystyrene externally over a drainage plane, with an unvented wood frame insulated attic and roof assembly.

Adding air-sealing and rigid foam insulation at the wall-to-overhanging floor juncture at the outside corner of an existing home

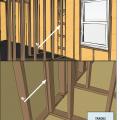

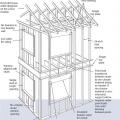

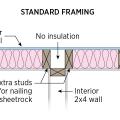

Advanced framing details include corners that are constructed with fewer studs or studs aligned so that insulation can be installed in the corner.

Advanced framing details include framing aligned to allow for insulation at interior-exterior wall intersections.

Advanced framing details include open headers and reduced framing around windows and two-stud corners to allow more room for insulation in the wall cavities while reducing lumber costs.

Advanced framing techniques including 2x6 walls spaced at 24 inches on center and ladder blocking at wall intersections allow more space for insulation in the wall cavities while open-web floor joists provide space between floors for ducting.

After attaching netting to the 2x6 studs, workers fill the wall cavities with R-23 of blown fiberglass made from recycled bottles.

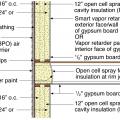

After spraying the 2x6 wall cavities with 2 inches (R-13) of closed-cell spray foam, the walls are covered with netting and an additional 3.5 inches of fiberglass (R-13) is blown in.

Air seal floor joist cavities under kneewall with rigid foam, plywood, or OSB caulked in place

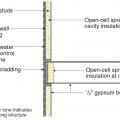

An installer fills these wall cavities with spray foam insulation, which will be trimmed flush with the stud faces after it dries and hardens.

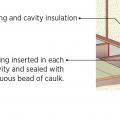

Attach the interior 2x4 wall to the exterior wall top plate with a flat metal connector plate

Baffles will keep insulation out of the soffit vents and wind out of the insulation in this vented attic.

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

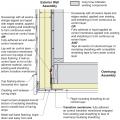

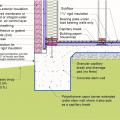

Brick veneer framed wall supported by a concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

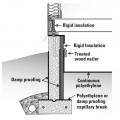

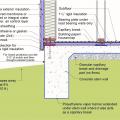

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and lapped up each wall or pier and fastened with furring strips or equivalent

Closed-cell spray foam insulation is added to the wall cavities of an existing exterior wall

Completed wall retrofit of masonry home (on right) showing new lap siding attached over four inches of rigid foam; windows were boxed with plywood to accommodate depth of foam plus 1x4 furring strips

Concrete is poured into the rigid foam shell of the insulated concrete form (ICF) walls; a plastic water barrier has already been installed to protect the below-grade wall surfaces.

Concrete slab-on-grade foundation with a turn-down footing insulated on its top surface, showing anchorage of the wall to the foundation for seismic resistance

Construct a double wall consisting of two framed walls forming a wide wall cavity for more insulation in the home’s exterior walls.

Deep energy retrofit showing insulation sprayed on exterior of walls over existing siding

Dense-packed blown fiberglass insulation completely fills the wall cavities with no gaps or voids.

Drywall was removed and the existing 2x4 walls were filled with 3.5 inches of dense-packed cellulose. Outside, the ½-inch plywood was topped with house wrap, 1.5 inches closed-cell rigid foam, 1x3 furring strips, and fiber cement siding.

Existing low-slope (“flat”) roof and brick masonry walls with a new fully adhered air barrier membrane plus polyisocyanurate rigid foam insulation and a roofing membrane water control layer

Expanded polystyrene insulation is installed with joints taped and lath attached in preparation for the application of stucco

Extension boxes of plywood built around the windows on this wall retrofit will be flush with the outer layer of exterior rigid insulation

Exterior fiberglass insulation on this new home was (incorrectly) cut to terminate below-grade after backfill, which will expose the above-grade portions of the foundation wall to cold temperatures