Showing results 1 - 37 of 37

A continuous layer of polyethylene covers the crawlspace floor and is attached to the wall with wood nailing strips

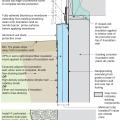

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

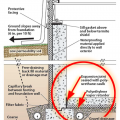

Capillary break at all crawlspace floors using ≥ 6 mil polyethylene sheeting, lapped 6-12 in., and lapped up each wall or pier and fastened with furring strips or equivalent

Concrete is poured into the rigid foam shell of the insulated concrete form (ICF) walls; a plastic water barrier has already been installed to protect the below-grade wall surfaces.

Existing low-slope (“flat”) roof and brick masonry walls with a new fully adhered air barrier membrane plus polyisocyanurate rigid foam insulation and a roofing membrane water control layer

Exterior fiberglass insulation on this new home was (incorrectly) cut to terminate below-grade after backfill, which will expose the above-grade portions of the foundation wall to cold temperatures

Exterior XPS basement insulation is correctly installed to completely cover the foundation wall

Foil-faced rigid foam and spray foam can be used to insulate a basement on the interior; use good moisture management techniques to keep the basement dry

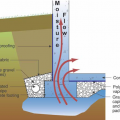

Good water management practices like sloping grade away from house, and installing gutters, perimeter drain pipe, a capillary break, and free-draining soils or drainage mat protect the foundation from water saturation.

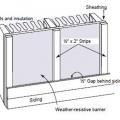

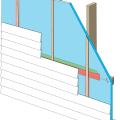

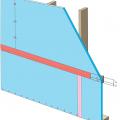

Over the taped rigid foam board, 2x4 furring strips provide a ventilating air gap and drainage plane under the engineered wood lap siding. The furring strips were attached with structural screws to provide an attachment surface for the siding.

Polyethylene completely covers the floor of this crawlspace and is attached to the walls and piers as well

Polyethylene is being attached to the crawlspace floor and walls with plywood furring strips

Proper flashing around windows is especially important when the rigid foam serves as the drainage plane in the wall

Right - Basement slab with a capillary break of either gravel or a drainage mat.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Polyethylene sheeting vapor barrier is installed and sealed to the crawlspace walls with mastic

Right: All joints in the rigid foam are taped to keep stucco out of joints for even drying. Mesh tape (shown here) is used with expanded polystyrene (EPS); acrylic sheathing tape or self-adhered membrane is used with XPS

Rigid foam insulation can serve as the drainage plane when all seams are taped. Furring strips provide an air gap behind the cladding.

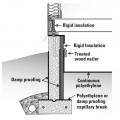

Rigid insulation and water control layers are installed on the exterior of a flat foundation wall; spray foam insulates the rim joist

Seams in the ICF block are sealed so the EPS foam surface can serve as the drainage plane; no house wrap is needed.

Spray foam extends down the inside of the foundation wall to the uninsulated slab; because the wall lacked exterior perimeter drainage, the slab was cut and an interior footing drain was installed.

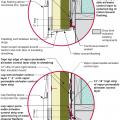

Tape horizontal joint with minimum 3" wide tape placing tape offset high on the joint, adhearing to the upper sheet without wrinkles

Terminate 4" tape with 2" wide tape placing tape offset high on the joint, 2/3 of the tape should be adhered to the sheet of insulation

This exterior wall retrofit permits drying to the exterior of a sill plate installed on an untreated flat foundation wall

Vapor-permeable mineral wool insulation is installed on the exterior side of the sill beam during an exterior wall retrofit to allow the sill beam to dry to the outside

Wrong – The polyethylene sheeting vapor barrier is not attached to the piers with mechanical fasteners